Autonomous mobile robots (AMRs) are genuinely revolutionizing warehouse operations. As a Warehouse Operations Manager, Director, or VP of Supply Chain, you understand the constant push for efficiency and innovation in logistics.

The global market of AMRs for warehouses and distribution centers surpassed $1.8 billion last year and is expected to reach US$41.B within the next 3 years. This represents remarkable growth in a short period, especially when compared to the global industrial robotics market, which stands at $17.7 billion. To understand this rapid expansion, we should examine how companies benefit from AMRs and how these robots, equipped with advanced navigation and automation capabilities, are dramatically altering warehouse operations, streamlining processes, and enhancing productivity.

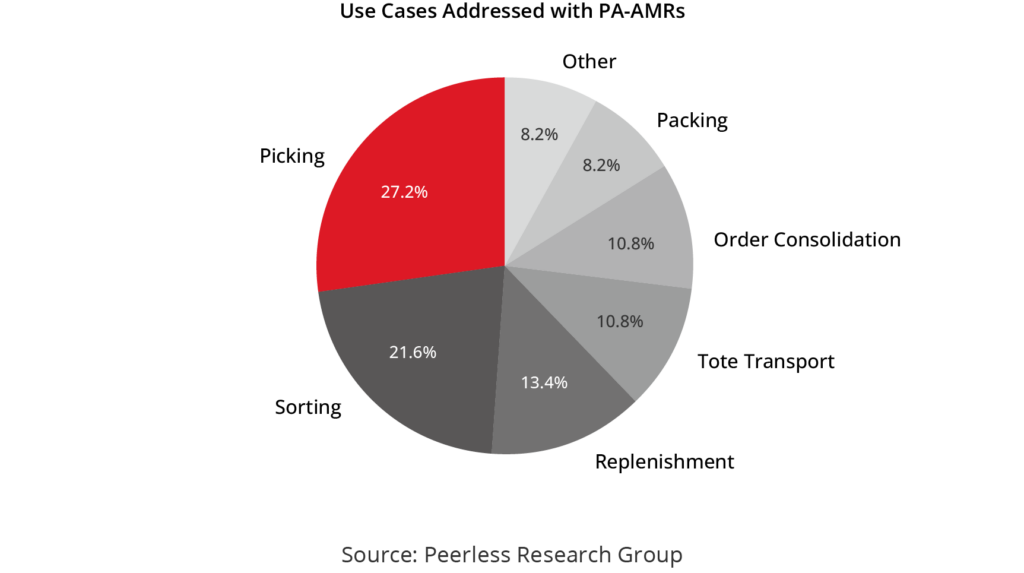

The pie chart illustrates the distribution of use cases addressed with PA-AMRs today:

Specifically, Rapyuta’s automated robots are changing the game by seamlessly integrating into existing workflows, offering your warehouse flexibility, scalability, and significant cost savings. AMRs are reshaping the future of warehouse management, bringing a new level of precision and performance to the industry.

Top 10 Benefits of Implementing AMRs in Warehouses

Automated robots navigate their environment without human intervention, using a combination of sensors, artificial intelligence. They can understand and interpret their surroundings to move efficiently and complete tasks like transporting goods within a warehouse. Unlike traditional mobile industrial robots, which typically follow fixed paths or rely on extensive programming, Rapyuta PA-AMRs are more flexible and adaptive. They can dynamically adjust their routes in real time, responding to changes and obstacles in their environment, making them ideal for complex and constantly evolving warehouse settings.

Increased Efficiency

In metropolitan areas of the US, direct labor rates exceed $20 per hour to attract workers. Despite this, retention remains low, with average turnover rates for US warehouses exceeding 37%. These challenges are compelling warehouse operations to minimize repetitive and low-value tasks, reduce unnecessary walking, and ensure that associates are focused on the most effective activities.

Increasing efficiency and effectiveness are classic challenges of Industrial Engineering and Operations Management that AMRs have proven to solve exceptionally well. AMRs streamline operations by taking over repetitive and time-consuming tasks, such as transporting goods within the warehouse, without large capital equipment. Connected to warehouse software through the Rapyuta.io platform, associates spend less time searching for items. Rapyuta.io streamlines deployment, site management, and dev ops, enhancing overall operational efficiency. This automation reduces the dependency on manual labor, allowing your workforce to focus on more strategic activities. This also makes their work more engaging, increasing retention. By optimizing the movement of materials and focusing on efficiency, AMRs enhance overall productivity and minimize delays, ensuring that your operations run smoothly and efficiently.

To learn more, read the linked case study of a company who faced challenges of hiring and retention, where traditional push carts and handheld devices were central to their operations.

2. Flexibility and Scalability

One of the standout features of AMRs is their adaptability to different and changing warehouse environments. Whether you are a 3PL adding new clients (and products) frequently or need to scale up operations during peak seasons, AMRs can seamlessly adjust to new configurations and increased workloads. This flexibility means you can rely on them to meet the dynamic demands of your business without significant disruptions.

3. Cost-Effectiveness

As an automated solution to common warehouse operation challenges, the cost of implementing AMRs, especially PA-AMRs, has been rapidly decreasing as their popularity has skyrocketed and the technology has scaled.

While any change may seem daunting, Rapyuta offers a unique ROI guarantee program and flexible pricing options to reduce the risk. Businesses can opt for low upfront costs, eliminating initial financial barriers and allowing them to seamlessly integrate Rapyuta Robotics’ solutions into their operations. Additionally, shorter minimum contract periods provide flexibility for businesses seeking to test the waters of automation before committing to a long-term engagement. By reducing the reliance on manual labor, AMRs help decrease labor costs and minimize errors that can lead to costly mistakes.

4. Enhanced Picking Accuracy and Speed

Pick assist robots are game-changers when it comes to enhancing picking accuracy and speed in warehouses. These robots work alongside human workers to streamline the picking process, reducing errors and significantly boosting efficiency. By handling the more mundane aspects of picking, such as locating and transporting items, pick assist robots free up your team to focus on more complex tasks, ultimately leading to faster order fulfillment and improved customer satisfaction.

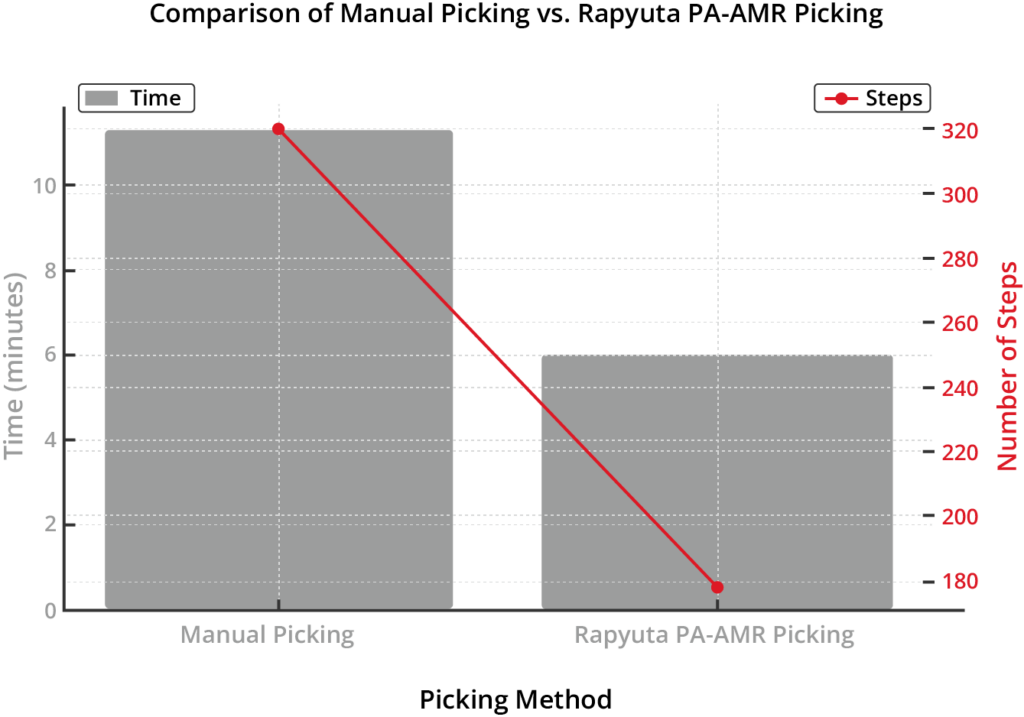

Below infographic illustrates the efficiency gains achieved by using Rapyuta PA-AMR Picking over Manual Picking.

Measurement Conditions: The comparison between Manual Picking and Rapyuta PA-AMR Picking was conducted under the following conditions:

- Area: The picking operations were performed in a 4,300 square feet area.

- Number of Lines: The setup included 22 lines.

- Number of Products: A total of 34 SKUs

5. Seamless Integration with Existing Workflows

Our PA-AMR (Pick Assist Autonomous Mobile Robot) solution takes warehouse automation to the next level. Designed to integrate seamlessly into your existing workflows, PA-AMRs enhance productivity by supporting your picking operations with precision and reliability.

6. Gain Storage Space

Real estate in warehousing is a major portion of operating costs, and construction or moving are herculean tasks everyone is happy to dodge. Improved slotting and better movement of goods from inbound to shelf to outbound and keeping products off the floor will obviously make better use of the available cubic space.

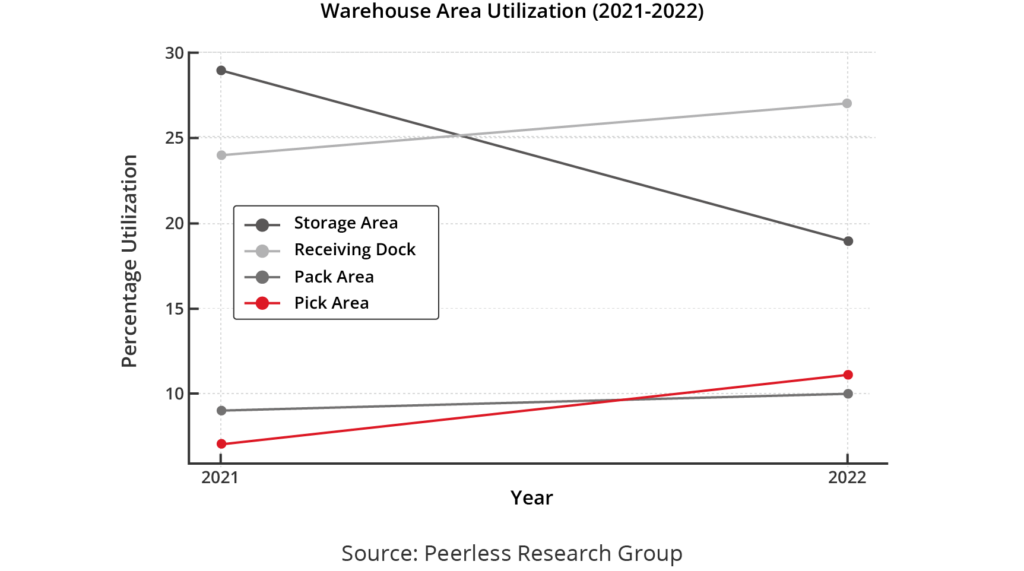

The line chart highlights the varying trends in warehouse area utilization from 2021 to 2022, showing a notable shift in how different areas are used. The most significant concern is the Pick Area, which saw an increase from 7% in 2021 to 11% in 2022. This upward trend suggests growing pressure on the picking operations, which could impact overall efficiency and productivity. Assuming this trajectory continues, we can expect the Pick Area utilization to potentially reach 15% by 2025.

Pick Assist Robots can be deployed without warehouse modifications. However, for those aiming to significantly enhance efficiency and companies in dramatic need for space, racks or shelves can be arranged in exceptionally dense configurations. Rapyuta PA-AMR excels in navigating aisles as narrow as 3 feet, offering a 20% space-saving solution, and thus optimizes warehouse space by increasing rack density within the same area.

7. Improved Worker Safety

By taking over physically demanding and repetitive tasks, AMRs reduce the risk of injuries and fatigue among warehouse workers. This leads to a safer working environment and allows employees to engage in more value-added activities, improving overall job satisfaction and productivity.

8. Enhanced Collaboration Between Humans and Robots

AMRs are designed to work alongside human employees, creating a collaborative environment that leverages both strengths. This synergy enhances overall efficiency and ensures that tasks are completed more effectively, combining the precision of robots with the decision-making abilities of humans.

9. Future-Proofing Operations

As technology continues to evolve, AMRs are proving to be the most popular choice for increasing ROI compared to conventional capital equipment. For instance, according to 2023 data from the market research firm Interact Analysis, AMRs contradicted the trend of slowing investments in warehouse automation last year. The research showed a decline in demand for warehouse automation overall, driven by an 8% drop in order intake for fixed systems (defined as anything bolted to the floor, including conveyors and shuttles). However, during the same period, demand for mobile robotic solutions grew by 38%. More warehouse and distribution center leaders see AMRs as their best strategic choice. They are perfectly suited for warehouse and distribution center operations. By investing in AMRs now, you are future proofing your warehouse operations, ensuring that you remain competitive and can adapt to technological advancements without significant overhauls. For further evidence and an example of how to proceed, consider this case study of how one company chose their path forward.

10. Reach Goals Faster

All these capabilities and advancements can be implemented and achieved more swiftly. Rapyuta dashboards, designed for transparency and clarity, simplify staff training and enhance productivity. In addition to user-friendly dashboards, Rapyuta reduces complexities in robot-human interactions by offering LED lights to guide associates in picking and placing items quickly and accurately. Achieve your ROI goals faster and maintain them effectively.

Explore a case study detailing how a third-party logistics provider (3PL), grappling with labor shortages and relying on short-term non-native speakers, transitioned from a paper-based pick-list process with high error rates to a digital process utilizing autonomous mobile robots (AMRs). Discover how this digital transformation reduced their labor dependency from 22 associates to 9, increased productivity to an astounding 800 picks per hour, and required less than one hour of operator training.

Conclusion

Autonomous mobile robots are transforming the landscape of warehouse operations by increasing efficiency, flexibility, and cost-effectiveness. From pick assist robots to advanced inventory management, AMRs offer a myriad of benefits that can significantly enhance your operations. As technology evolves, the integration and collaboration between humans and robots will become more seamless and productive. Explore the potential of AMRs in your warehouse to stay ahead of the curve and drive your business toward a more efficient and innovative future.Consider Rapyuta’s unique low-barrier to entry, low risk, high return-on investment with guarantees for your next strategic move. Contact Rapyuta Robotics to take your warehouse operations to the next level!