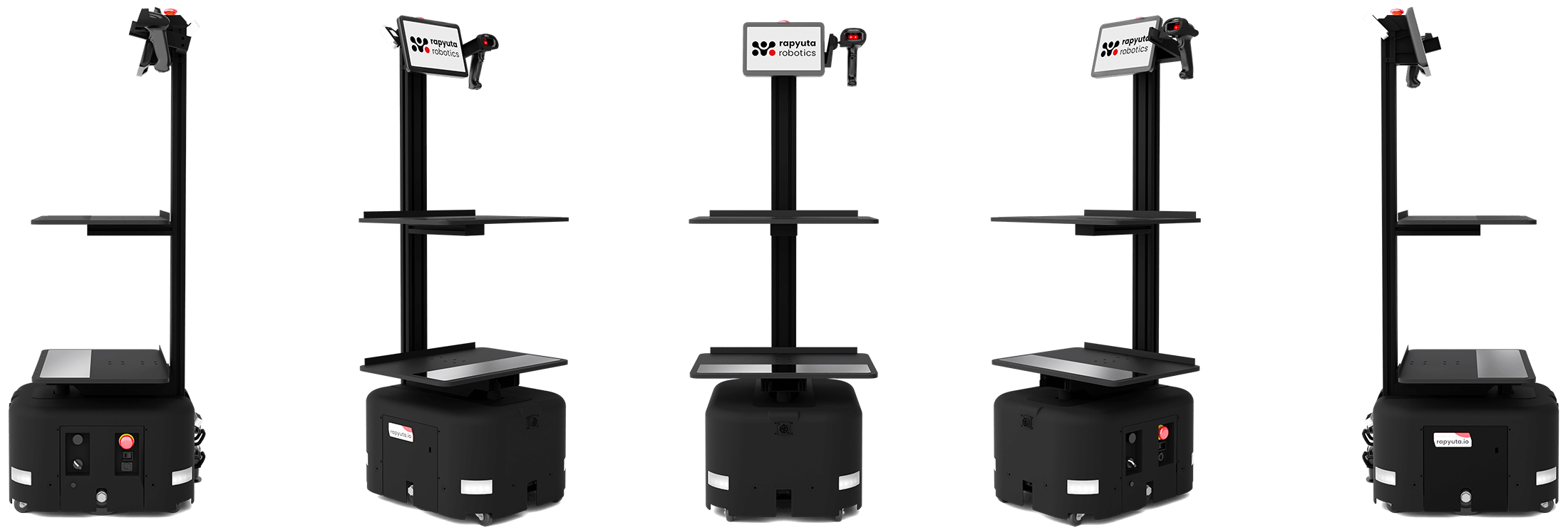

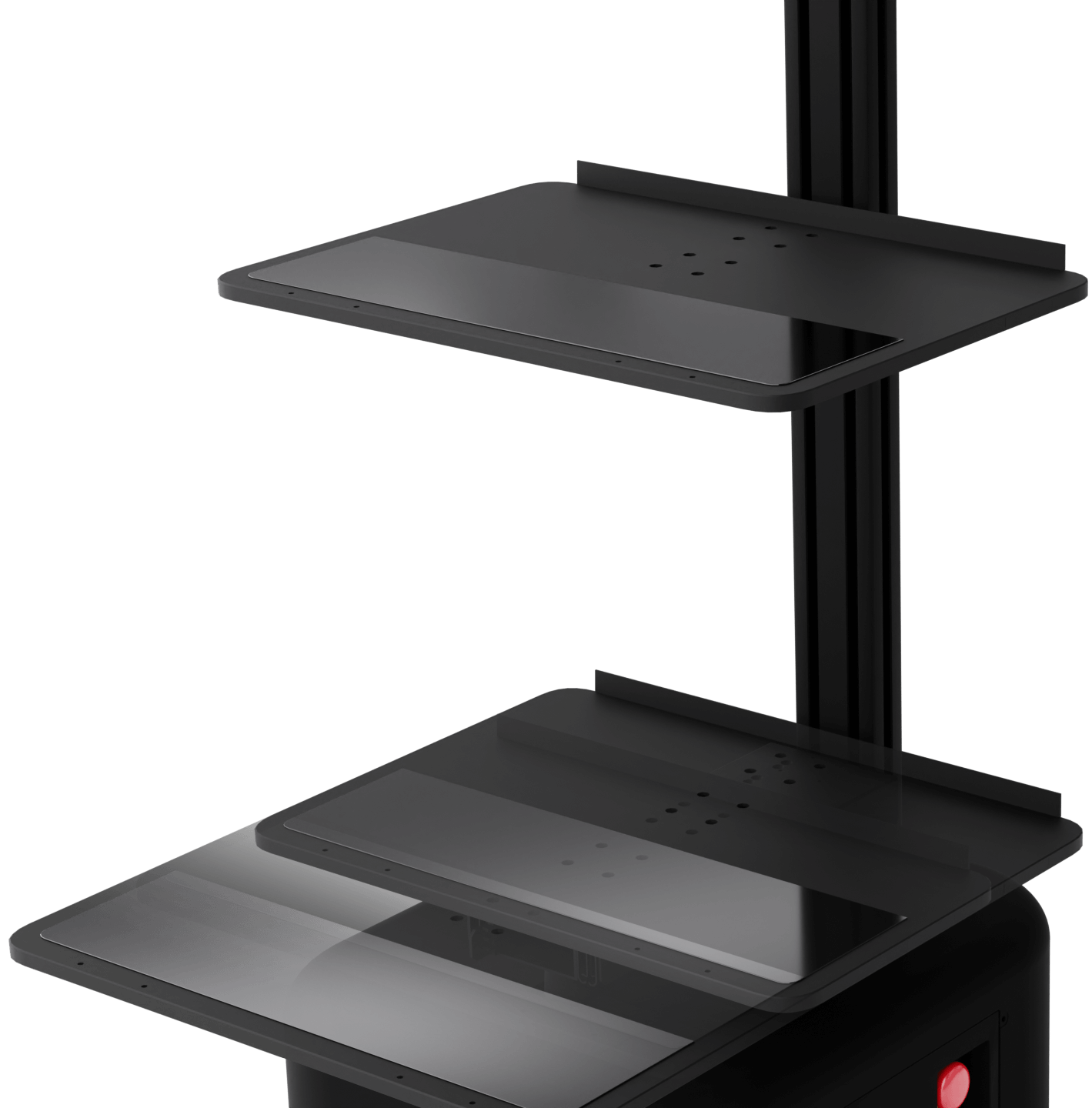

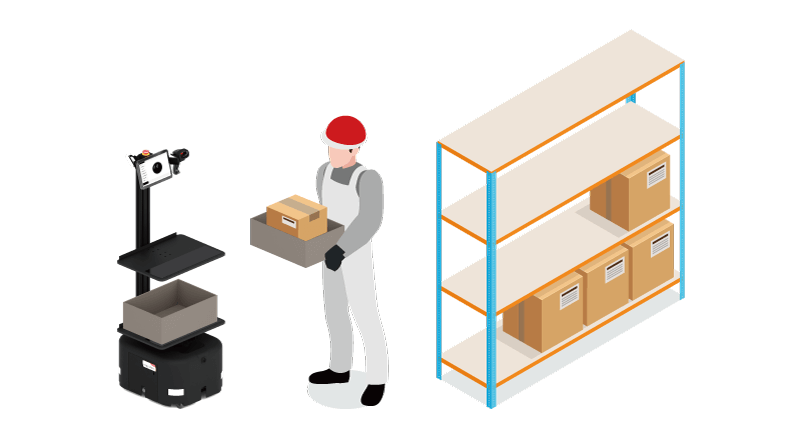

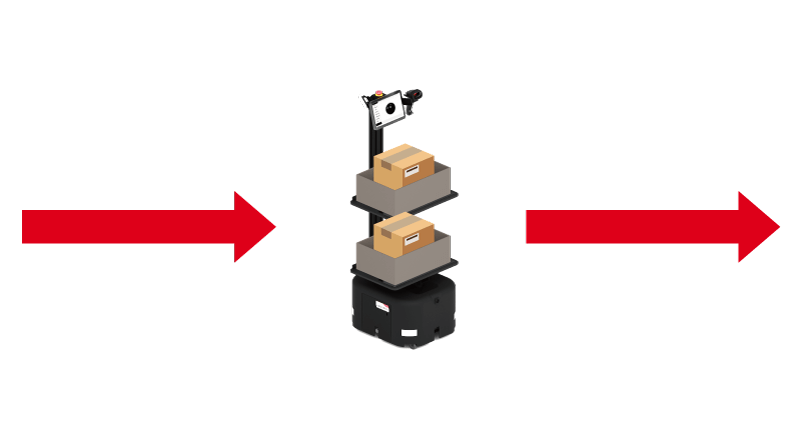

The pick assist robot Rapyuta PA-AMR developed by Rapyuta Robotics performs picking in collaboration with warehouse associates. AI suggests the shortest picking routes and also handles the transportation of items.

This robotics solution improves productivity and reduces the load on picking staff.

Rapyuta PA-AMR has been awarded the Good Design Award in 2023

Rapyuta PA-AMR has been awarded the Good Design Award in 2023

Rapyuta PA-AMR is a state-of-the-art robotic solution with simple integration, improve productivity in picking operations, reduce workers’ workload, and help the labor shortage.

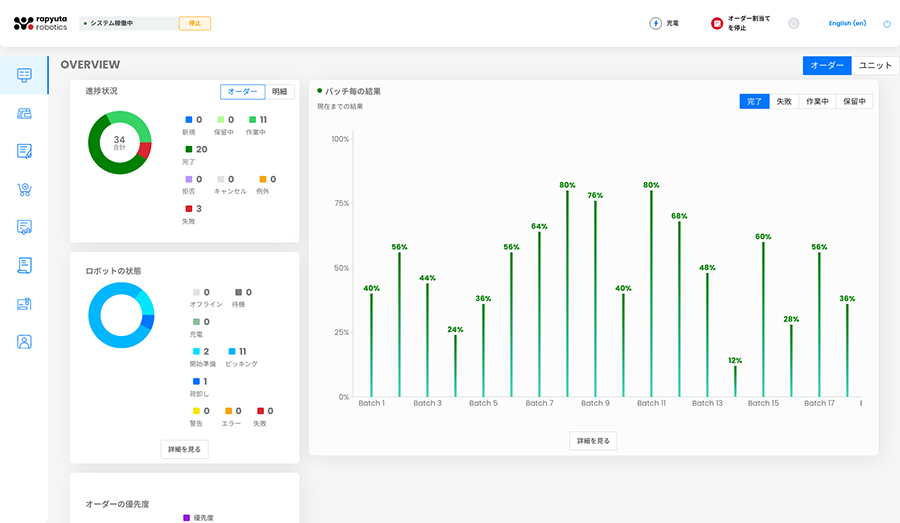

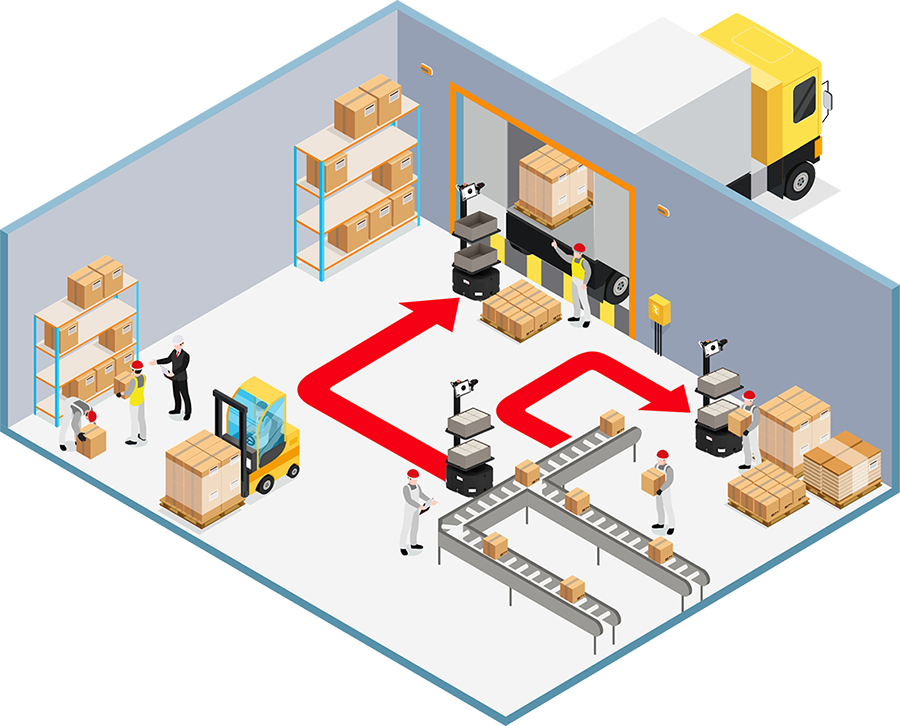

With the cloud robotics platform “rapyuta.io” and group control AI, multiple robots work together using optimal routes to transport packages.

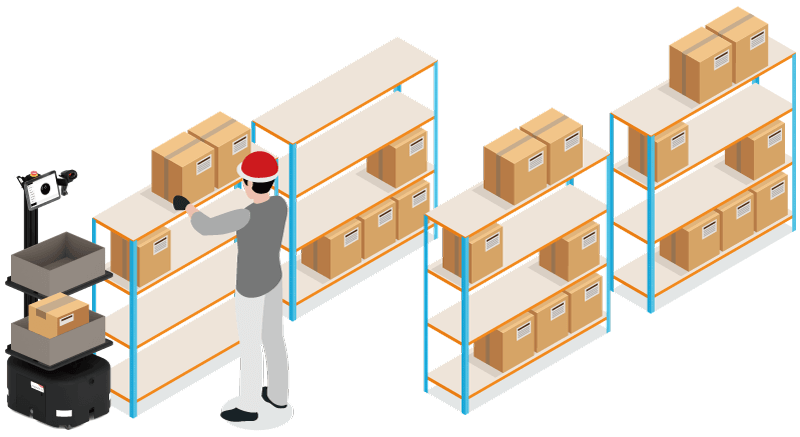

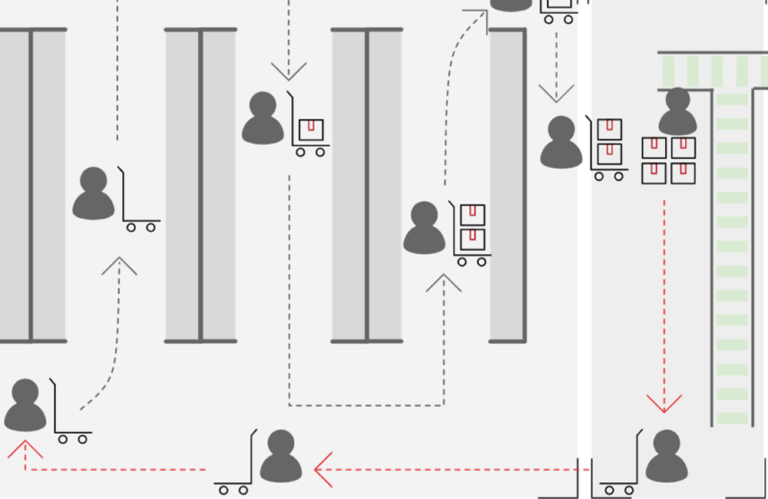

Picking staff follow the robot’s instructions and perform picking tasks accurately and efficiently, freeing them from the hassle of pushing carts, thereby increasing productivity and improving the working environment at the same time.

Since the system enables parallel processing with normal picking, it supports relatively large fluctuations in material volume.

The system is effective for sites with six or more picking associates. A fixed monthly fee (RaaS) is available to reduce the initial investment. This can be implemented directly into existing warehouse layouts, that makes it a solution many people can consider!

Rapyuta PA-AMR is used by a wide range of customers, including major Japanese 3PL operators such as Nittsu and SGL. Installation is very simple. There is no need to change the layout of the warehouse, and the system can be introduced without stopping the operation. AMR, a ready-to-use system, starts operation on the same day, just like a new warehouse associate.

Rapyuta PA-AMR consists of our original software, group control AI, and made-in-Japan hardware, making it agile and responsive to your needs. Optimization and efficiency improvement by group control not only saves manpower and labor, but also reduces the burden of hiring and training new staff. Even during busy periods, only a small number of additional staff need to be hired, making staffing easier.

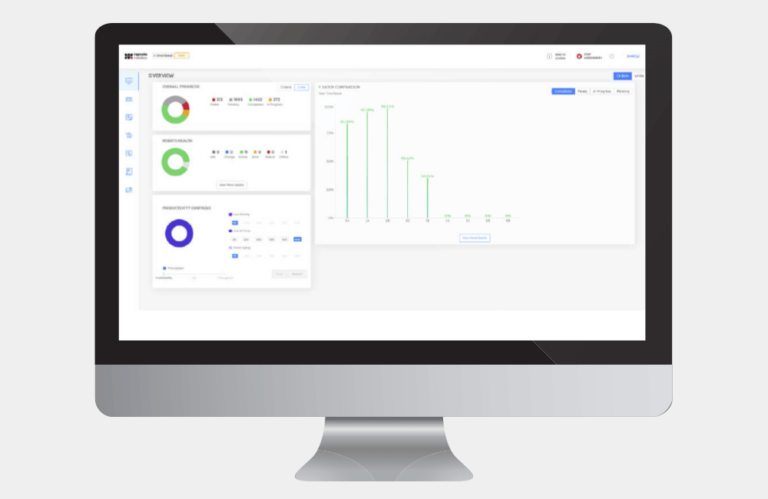

Collecting and utilizing data is a major management challenge that can determine the future success of your business. Rapyuta PA-AMR visualizes data from warehouses, which tends to rely on heavy human interaction. By collecting data efficiently and ahead of competitors, Rapyuta PA-AMR enables you to differentiate your services and support your business growth.

Easy to place and pick up items

Pick the target item from the temporary storage area and load it into AMR.

AMR autonomously transports to designated replenishment location.

Replenish the items.

From B2B parts centers that handle a variety of small items to warehouses with miscellaneous daily goods that are slightly larger in size or have a large number of items per pick, Rapyuta PA-AMR meet the needs of various industries.

In addition to an overview of how to use Rapyuta PA-AMR, product specifications and system configuration diagrams, key features such as “Container Size Change,” “Order Split” and “Picker Guide System” are introduced.

Picking staff spends 50-60% of their day walking and searching for items. Rapyuta PA-AMR improves productivity by automating this “walking” so that the staff can just pick and place.

No matter how good the vision or how good the robot looks, it is useless if it is not usable in the site.

We provide robotics and support for our customers to ensure that work efficiency is improved after the introduction of the robot in the facility.

Japan India USA