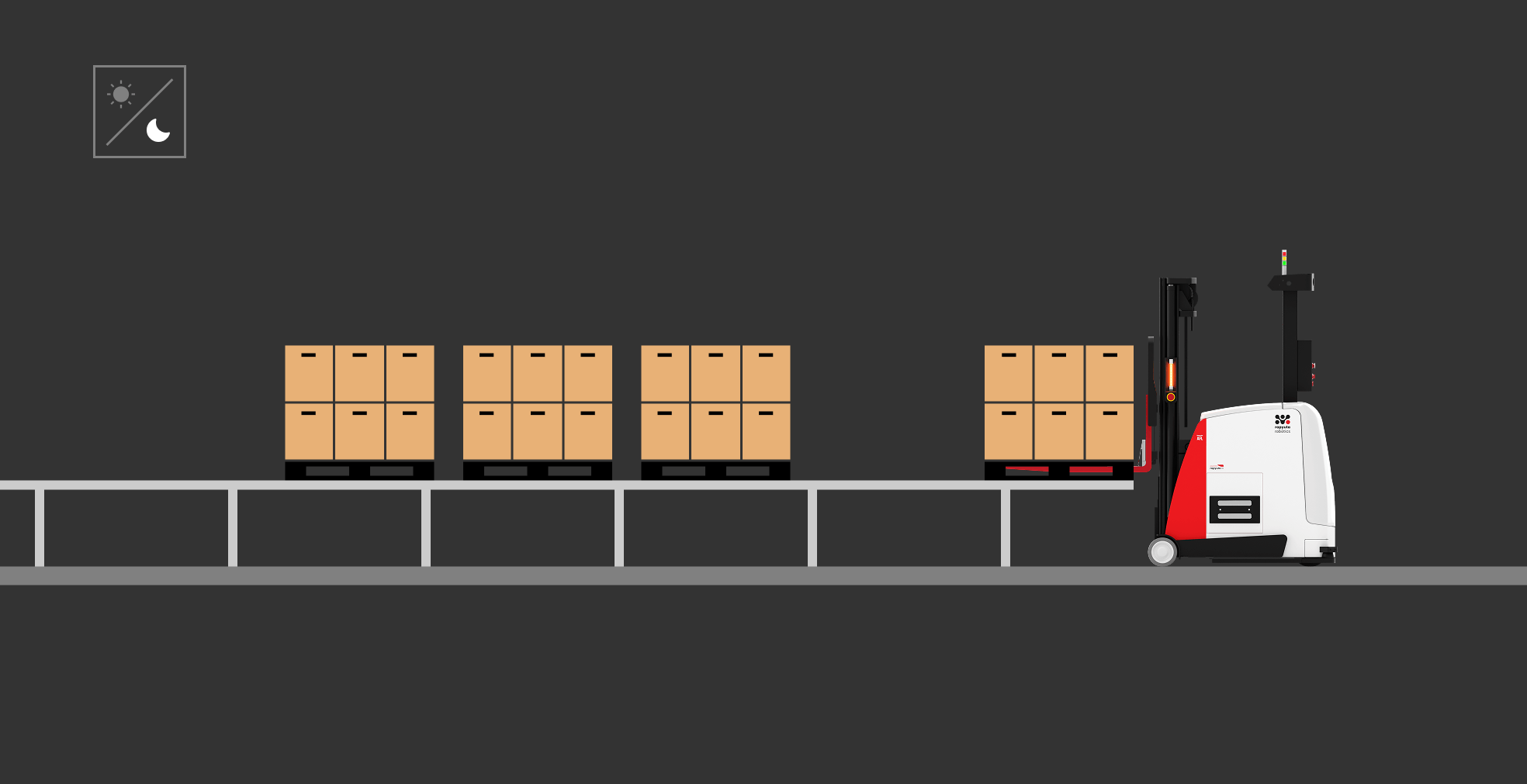

Rapyuta Autonomous Forklift uses the in-house developed robotics platform rapyuta.io™, an AI technology to flexibly respond to complex warehouse operations. The advanced self-positioning technology ensures safety and can be flexibly introduced into existing warehouses without the need for reflectors or magnetic tapes. Rapyuta AFL supports nighttime operations, allowing for early return on investment.

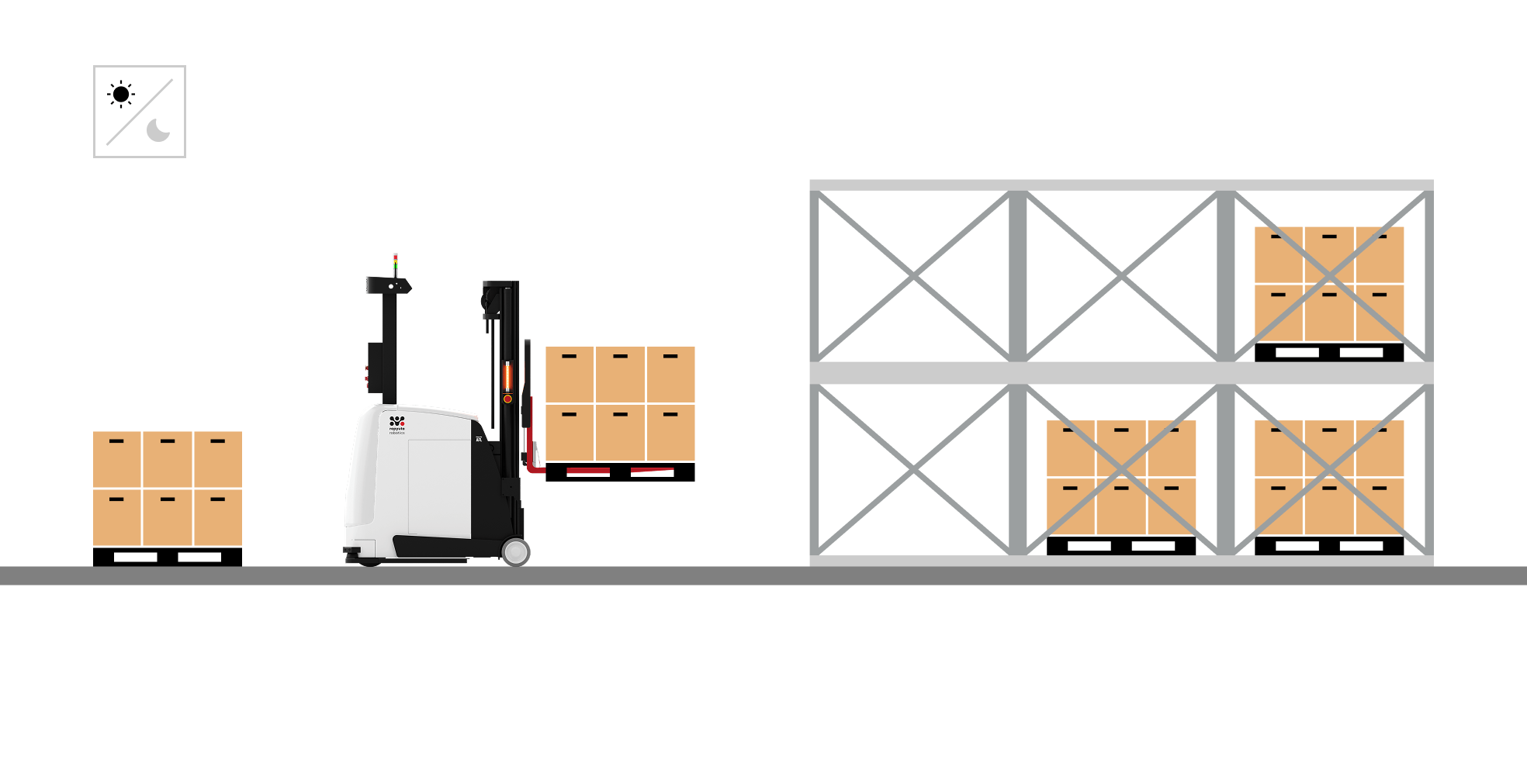

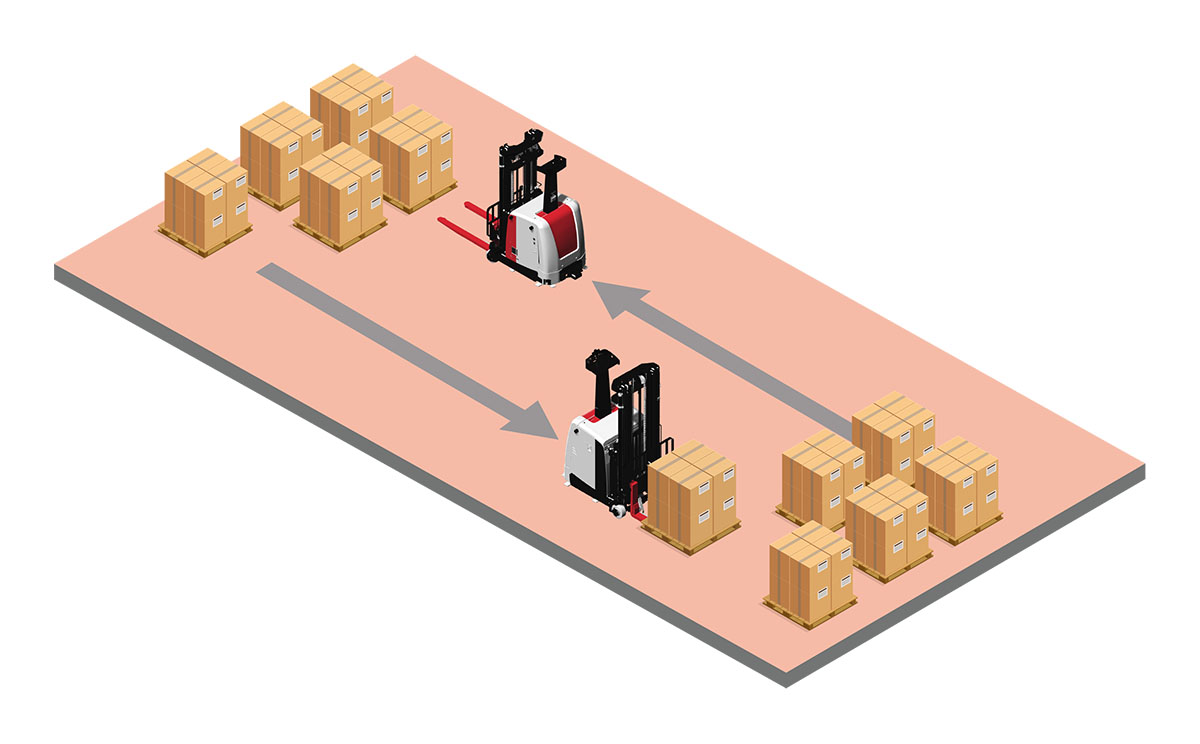

In addition to loading and unloading from standard fixed racks and storage spaces, Rapyuta AFL can also manage storage in flat areas and perform picking tasks. Furthermore, by integrating with WMS, it can be introduced to a broader range of operations and sites.

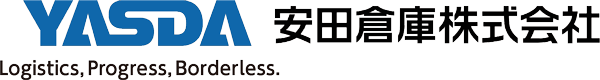

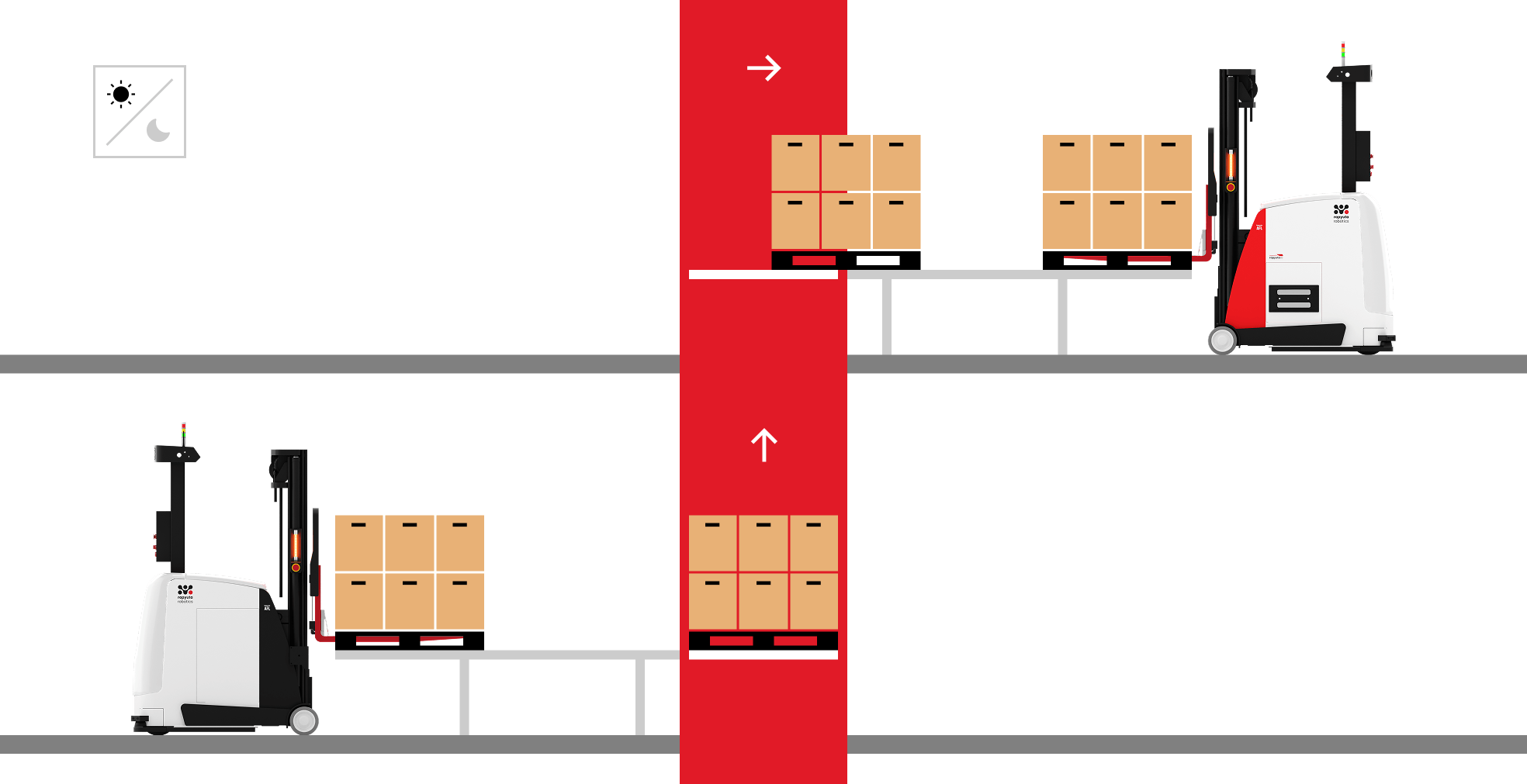

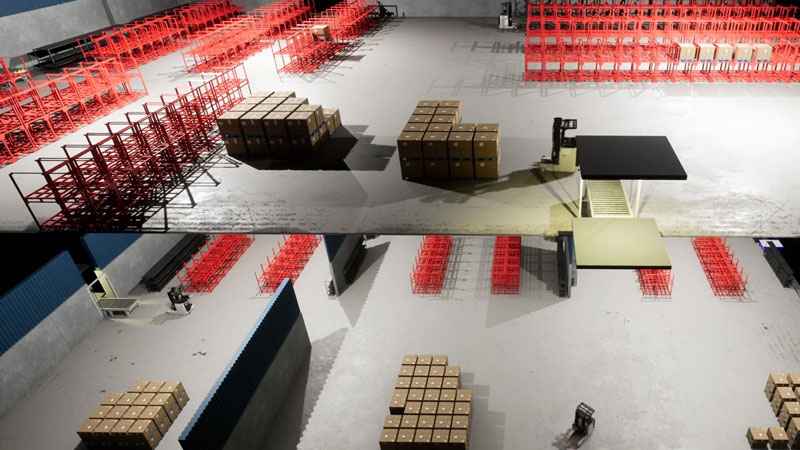

Loading of vertical conveyors from temporary storage areas on upper and lower floors.

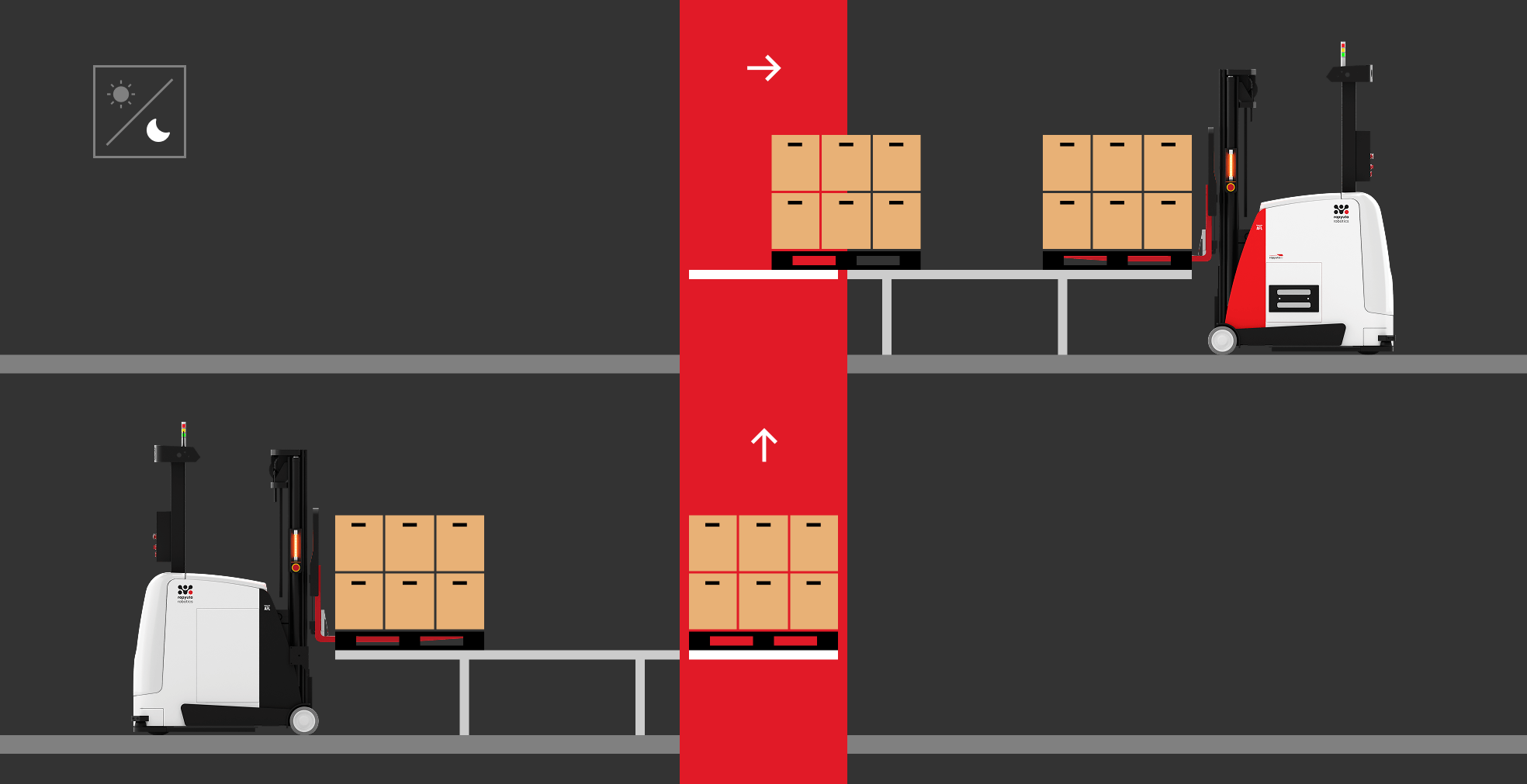

Conveyor belt transportation from shipping discharge to temporary storage area in a single-story building.

No reflectors or magnetic tape are required for robot’s self-positioning. Deployment into existing warehouses can be done smoothly and at the fastest speed in the industry*. Flexible response to operational and layout changes** is also possible.

* Based on our research results. The implementation period will vary depending on the content of the requirements at your site.

** Costs may be incurred when making layout changes.

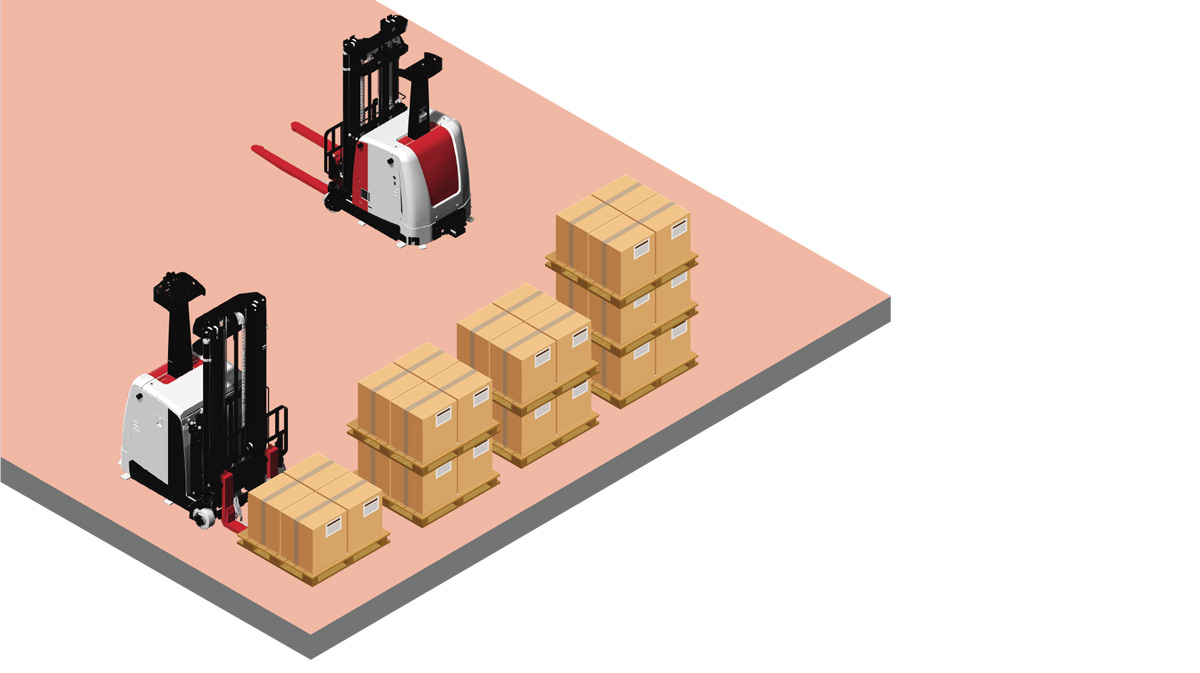

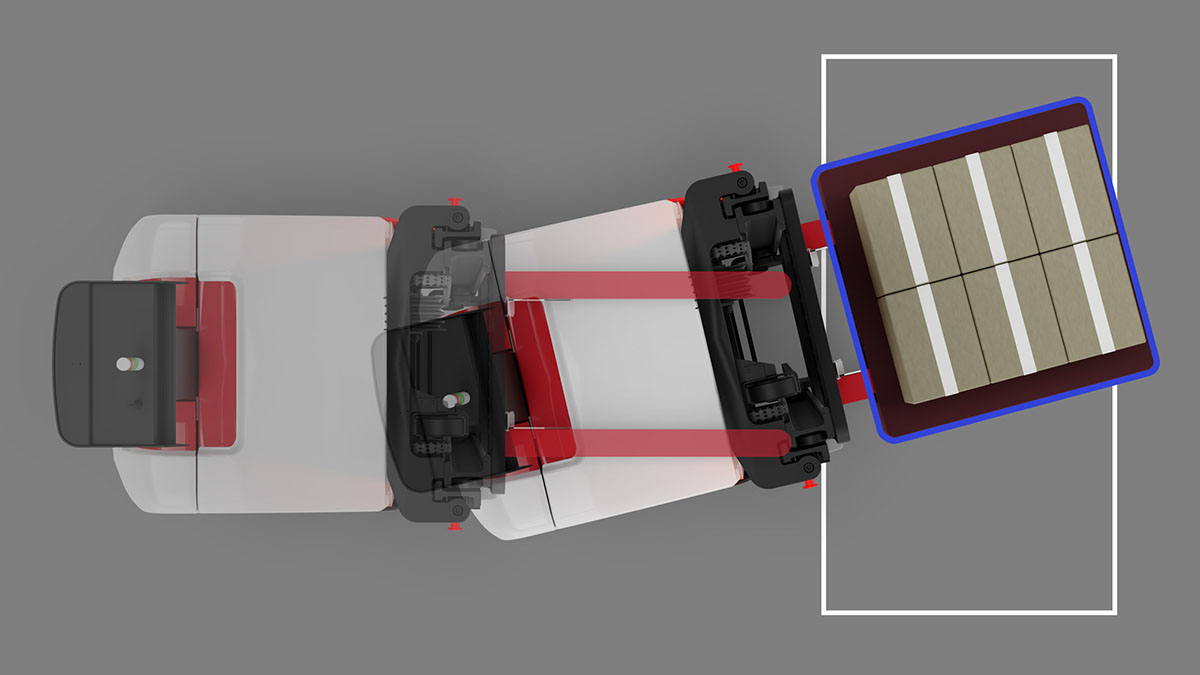

Not only can Rapyuta AFL handle pallets of various materials and sizes, but it can also flexibly handle special ones such as iron frame pallets.

Rapyuta AFL supports pallet stacking in 2 or 3 layers.

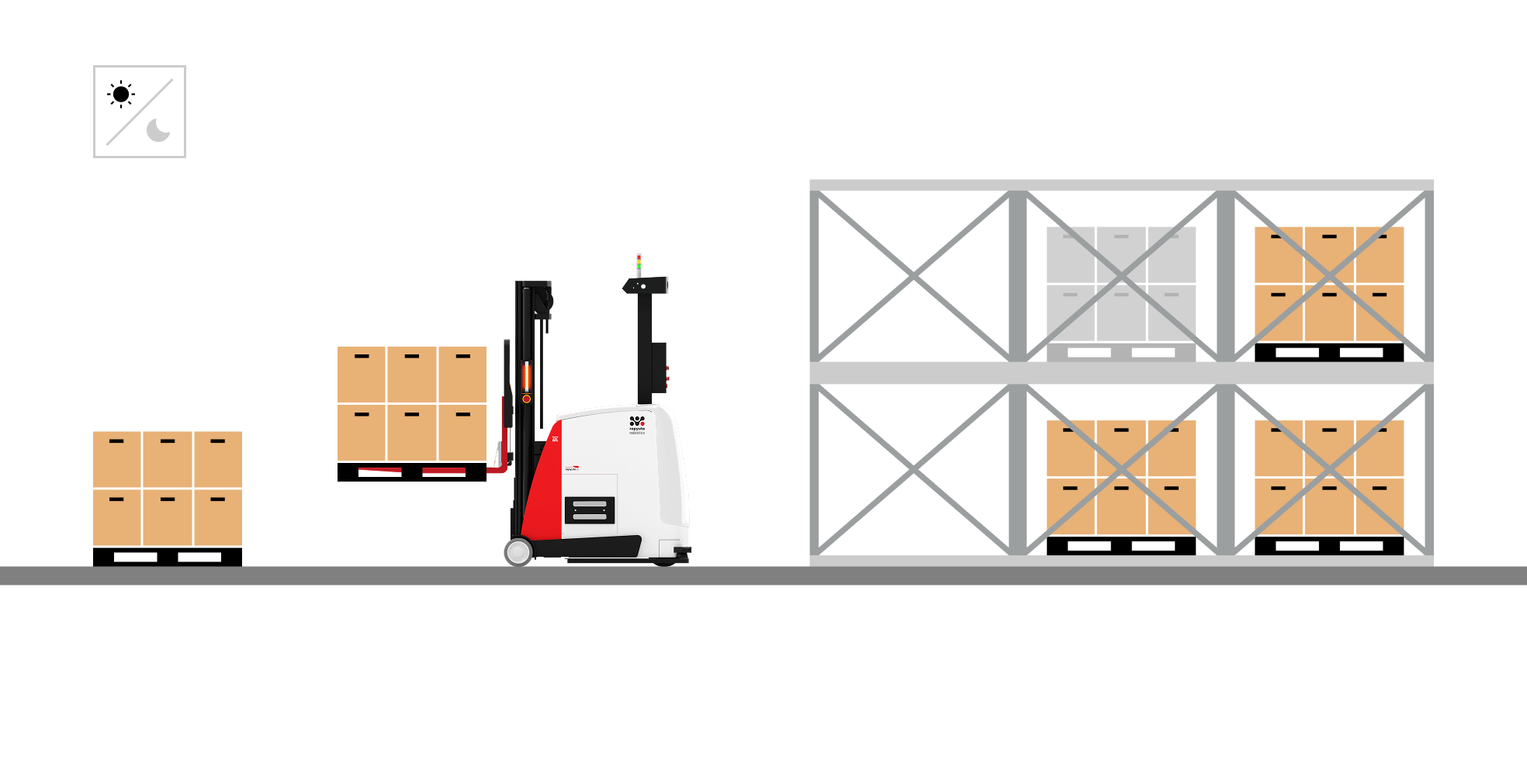

Even if the pallet is placed at an angle from the specified position, the pallet holes can be detected and the pallet picked.

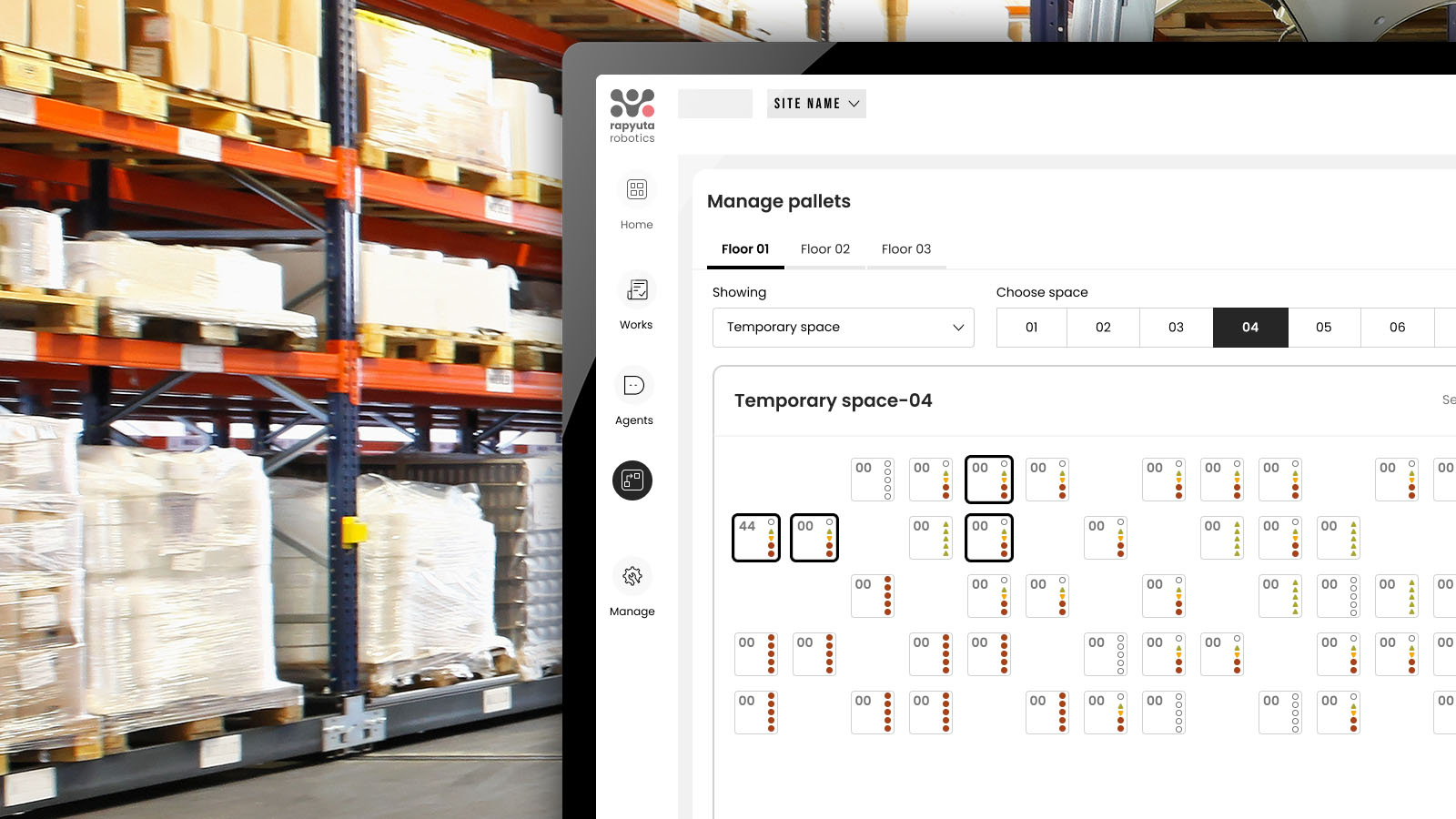

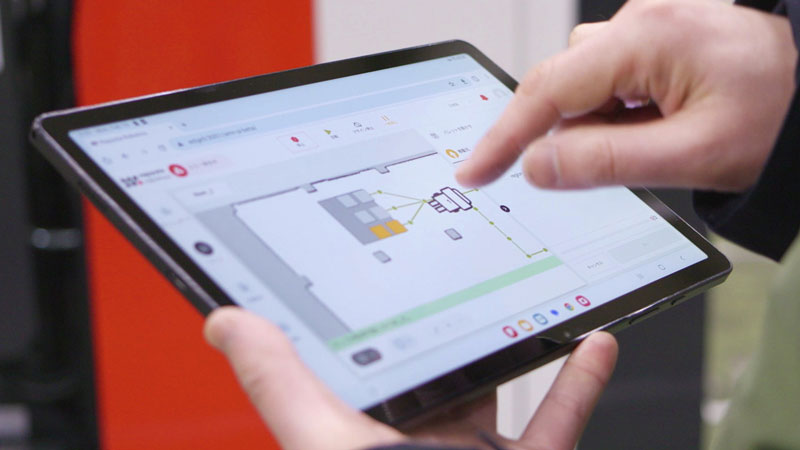

Loading instructions are easy. Just select the pick and drop locations on the tablet.

Available in Japanese and English. Easy to understand and use by everyone. Intuitive interface makes on-site operation simple.

Supports flexible and safe storage even in limited spaces. Supports 3-4 levels of fixed and mobile racks up to 4.5m.

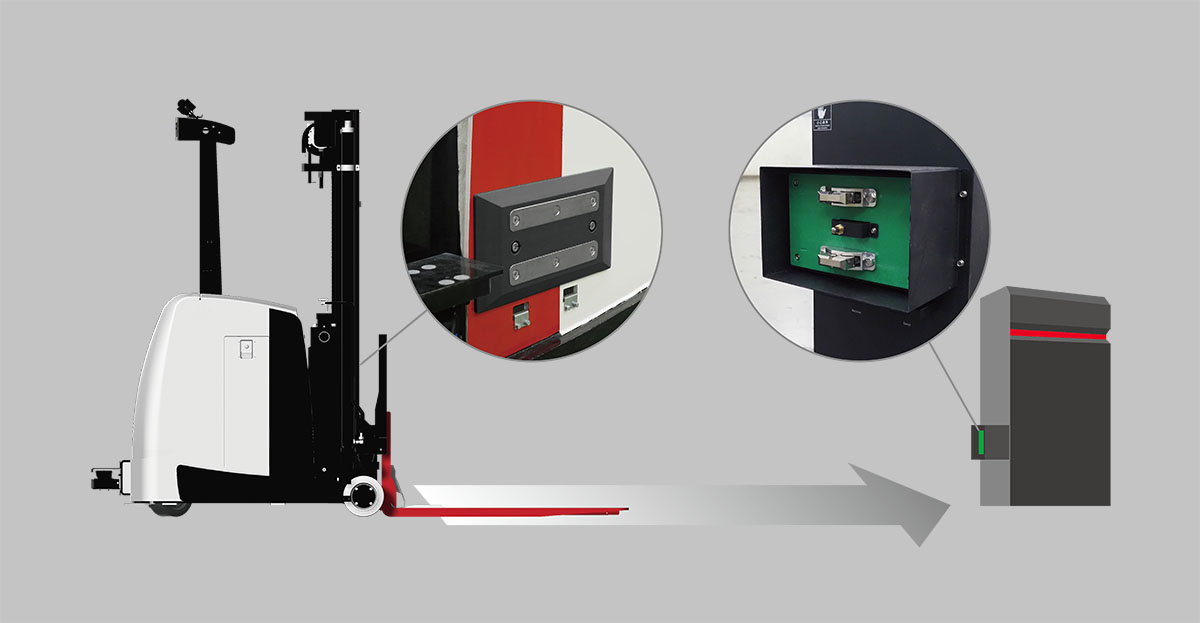

There is no need for workers to plug the device into a power outlet to charge it. The AFL automatically returns to the charging port and automatically charges. The lithium-ion battery allows charging to be completed in 3 hours.

AFL passage is possible with side clearances of 150-200mm on both sides. Clearance at the back is 50mm. Stacking and unstacking at random heights is also possible.

Supports two-tier loading and unloading, enabling efficient pallet transport.

Rapyuta AFL has allowed 30 pallets per hour to be transported at the deployment sites.

The system can be operated late at night, when it is difficult to secure staff, making it possible to realize an early return on investment.

Various dashboards are available for productivity monitoring, floor map, status monitoring, and temporary storage management. These dashboards can be accessed remotely, allowing you to see the warehouse status in real time.

The pallet can be placed further away using a “double stacking” feature by inserting the fork twice when lowering it. When there is distance between the forklift’s stop position and the conveyor, this will prevent the pallet from falling and stabilizes conveyor transport.

Customer support desk available 24 hours a day, 365 days a year. Software improvements are continued even after the robots have been deployed.

The robot performs a 360° scan from its starting point, utilizing laser point cloud data to detect obstacles and estimate its position.

Old model seen in the videos.

Rapyuta AFL is currently available in Japan. For more information, please contact us.

Japan India USA