On average, warehouse associates spend 50% to 60% of their time walking or finding the items.

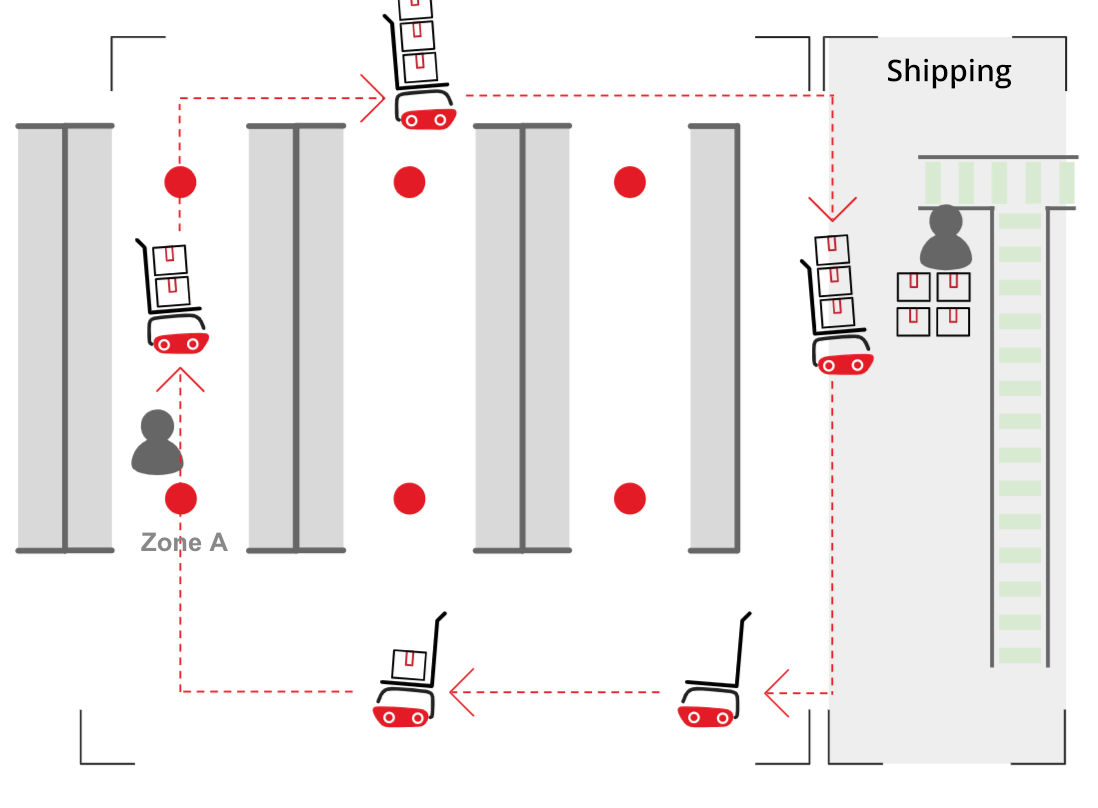

Rapyuta PA-AMR automates the walking time and lets the associate to focus on picking the items, increasing productivity.

The following two points are important to understand how AMR works.

AMRs do not work with the associates on 1 to 1 ratio, rather 2-3 units of AMRs work for every associate and s/he can keep picking the items (no idle time)

※ if AMR works on 1 to 1 ratio with associate, it becomes same as self driving picking cart. It reduces physical load but does not increase the productivity

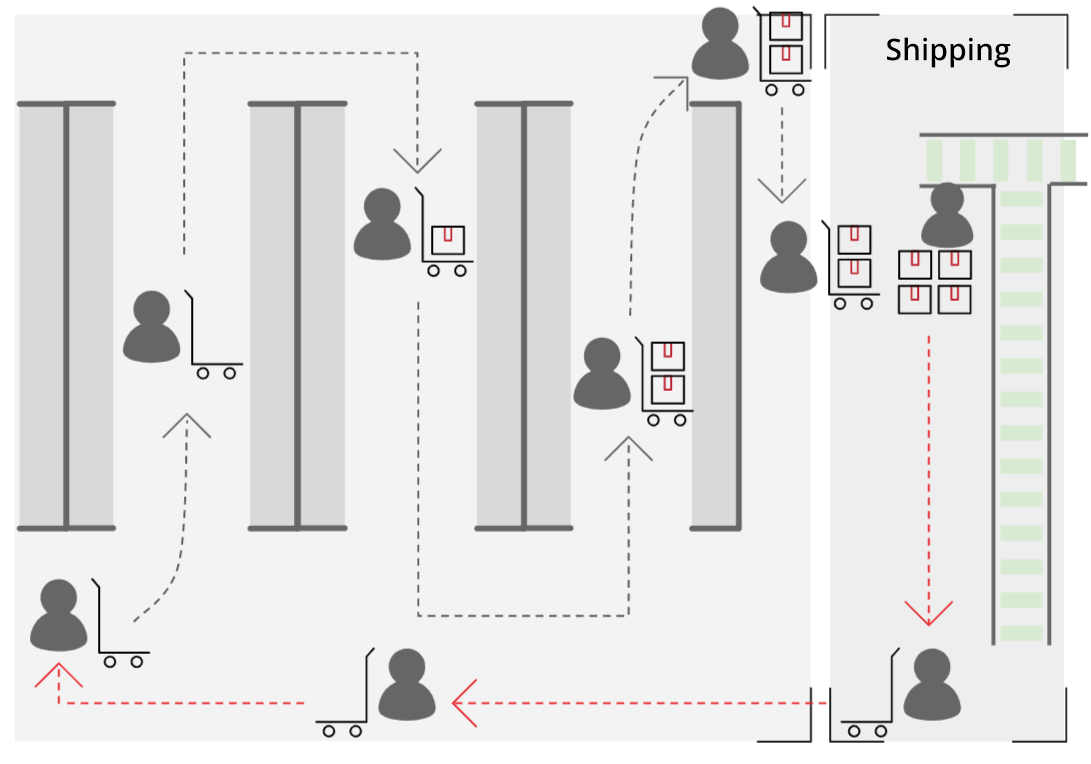

There are two types of walking: 1. Short distance walk within the same aisle; 2. Long walk across many aisles. AMR eliminates the long walk.

With short walking within the aisle and long walking across the aisles, 50% to 60% of the time is spent on walking, which does not add value.

If we can reduce walk time, pick productivity increases.

Because multiple AMRs work with every associate, there is no idle time of associates and productivity improves. With the higher productivity, handling demand fluctuation becomes easier.

The Rapyuta PA-AMR is demonstrated at Rapyuta Robotics’ office. Shelves are arranged similar to a warehouse, allowing visitors to experience how picking is done.

| 1 | Presentation (introduction of our company and explanation of Rapyuta PA-AMR) | 30 min |

| 2 | Rapyuta PA-AMR Demonstration (Explanation of Rapyuta PA-AMR and picking demo) | 30 min |

| 3 | Q&A | 20 min |

When considering the introduction of the system, the simulator allows the expected effects of warehouse automation to be verified in advance. Using an actual on-site layout, the software used in the actual Rapyuta PA-AMR is executed in a virtual environment to achieve a high degree of institutional verification.

Japan India USA