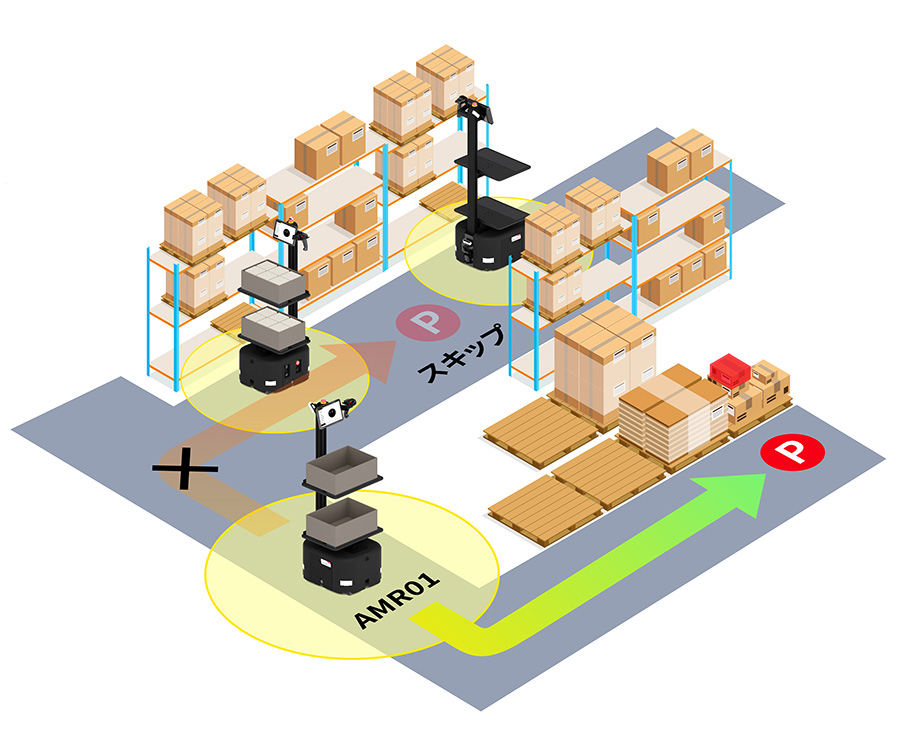

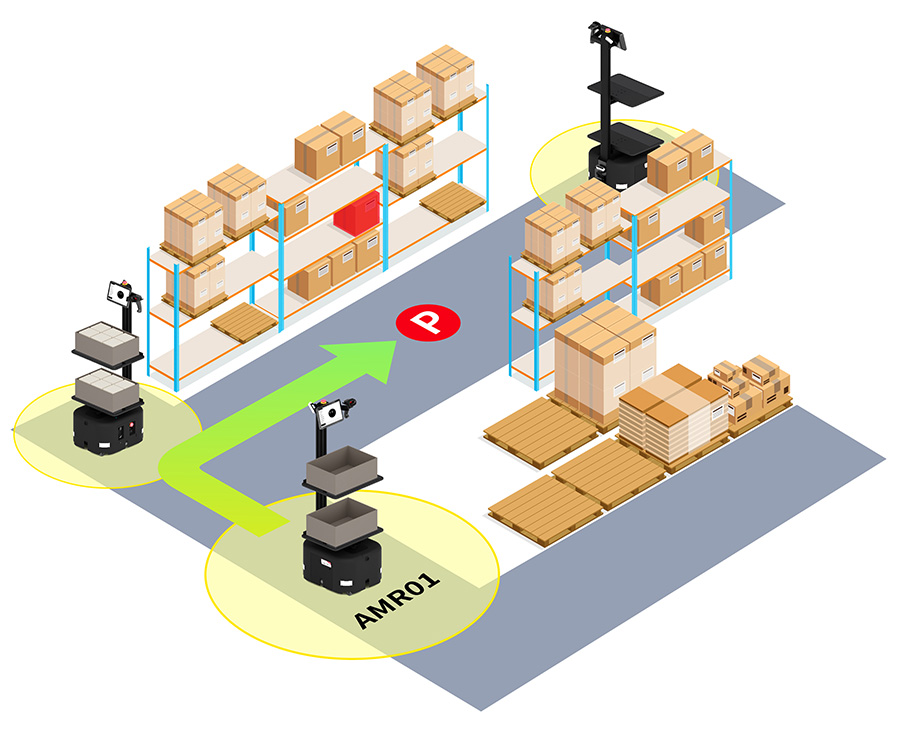

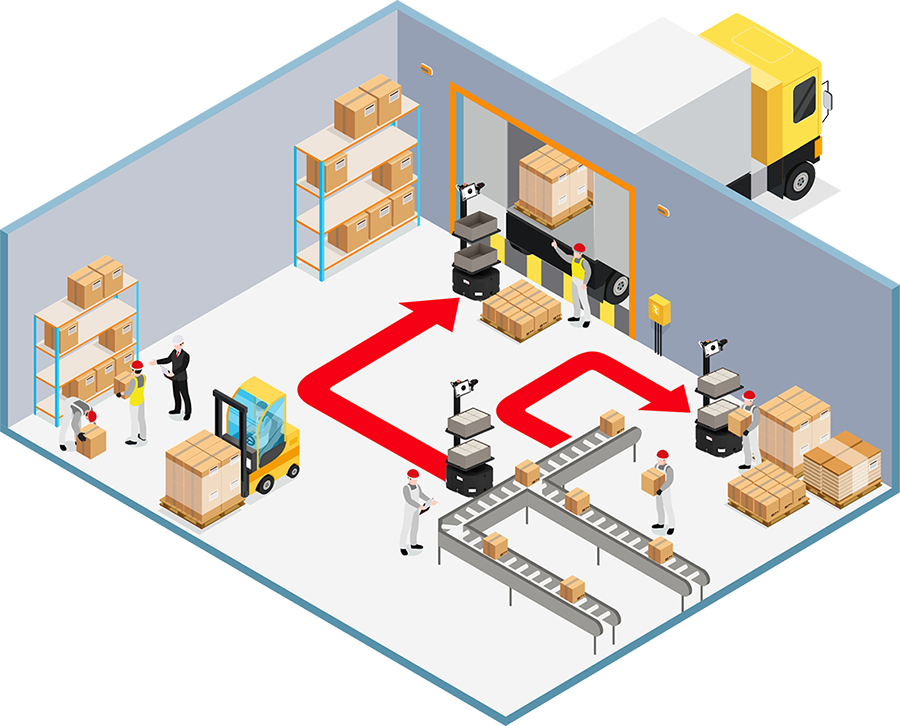

Situations may occur in warehouses where multiple robots cause excessive congestion near products and shelves where orders overlap.

The Dynamic Picking Function added in this update avoids traffic jams by automatically optimizing the order in which products are picked up between robots, achieving greater productivity than ever before.

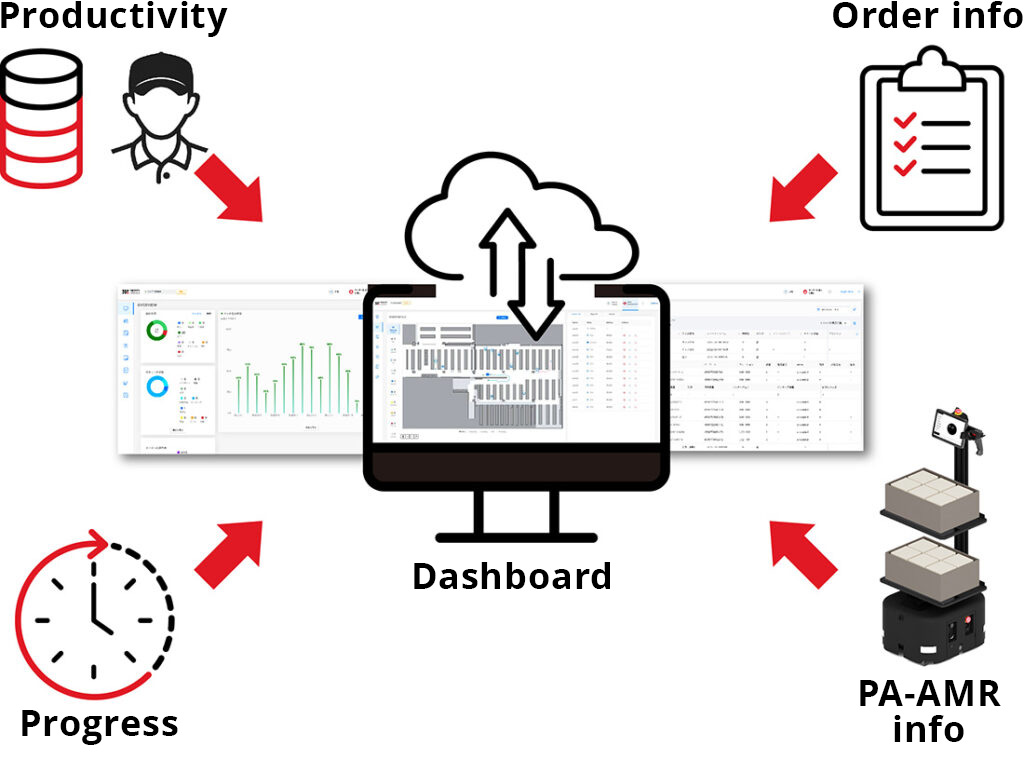

This dashboard update adds “overall productivity”, “individual productivity”, and a heat map showing the status of the picking area that visualizes order priority and progress management at the site.

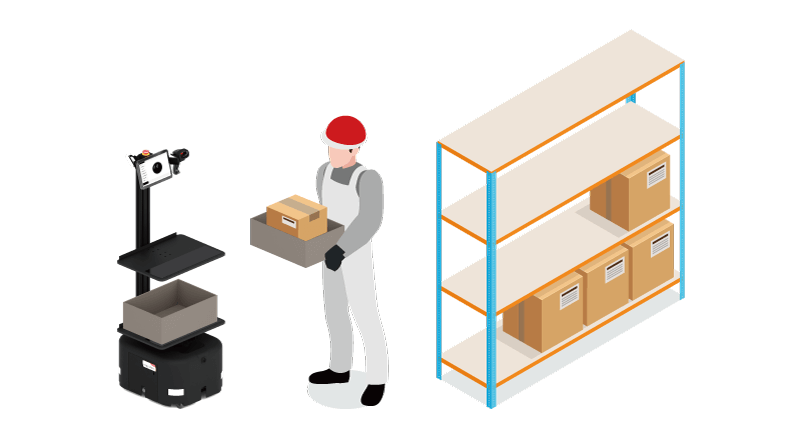

Rapyuta PA-AMR, when set to storage mode, transports the products that are scheduled to be stored at the temporary storage area to the designated location.

Store the product on the designated shelf based on the shelf number, product code, product name, or replenishment location displayed on the AMR operation panel.

High precision and efficiency in product storage can be achieved by this simple operation.

*This feature is provided as an option.

Pick the item from the temporary storage area and load it into the PA-AMR.

PA-AMR autonomously transports the items to the designated replenishment location.

Replenish items within the replenishment location.

Pick items from storage

▼

Concentrate replenishment products in temporary storage areas

Pick items from storage

▼

Concentrate replenishment products

in temporary storage areas

Set PA-AMR to

refill mode

▼

PA-AMR moves to the pre-registered loading location

Set PA-AMR to refill mode

▼

PA-AMR moves to the pre-registered

loading location

STEP1

Loading process

STEP2

PA-AMR moves to replenishment location

STEP2

PA-AMR moves to

replenishment location

STEP3

Replenishment

After the work is

completed,

PA-AMR moves

to the loading area.

After the work is completed,

PA-AMR moves to the loading area.

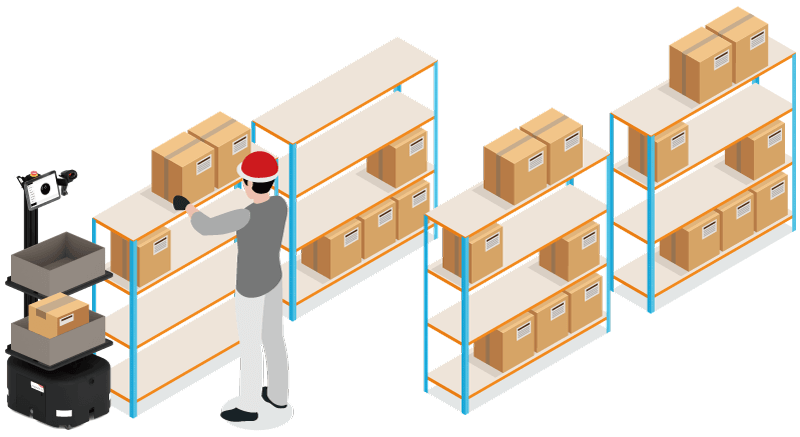

Pick the item from the temporary storage area and load it into the PA-AMR.

PA-AMR autonomously transports the items to the designated replenishment location.

Scan

product

barcode

Input

quantity

with control

panel

Products

placed on

top of

the tray

Specify the

location on the

operation panel

and proceed to

the next step

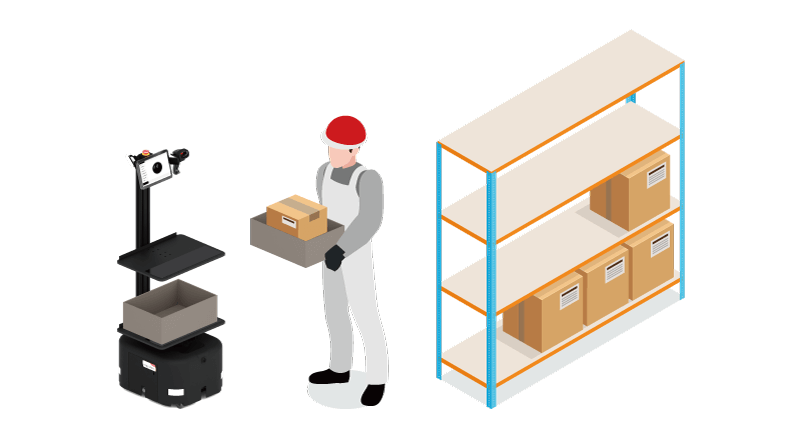

Replenish items within the replenishment location.

Scan

product

barcode

Input

quantity

with control

panel

Products

placed

on top of

the tray

Specify the location on the operation panel and proceed to

the next step

Scan

product

barcode

Display storage bin, product code, product name, and product location

Quantity

confirmation

Scan the

storage bin

and proceed

The scope of use of the Rapyuta PA-AMR can be expanded by using the “Fixed Point Transfer Function”, which allows the robot to be actively used for tasks other than picking.

Products that have been inspected at the warehouse’s inspection area are loaded onto the Rapyuta PA-AMR and transported to the shipping location (temporary storage area). After being transported, the Rapyuta PA-AMR moves back to the inspection station.

The “Put to Light” (mispicking prevention) function is an assistive function that reduces incorrect picks and improves productivity. When used,the LED lights mounted on the trays of Rapyuta PA-AMR light up to show the correct position for the picked item.

The LED lights up and specifies the location of the container, preventing containers from being placed in a wrong tray.

The color of the LED can be set to match that of the container, and the width of the indicator can be set to match the size of the container.

Specify the location of the container where the picked item will be placed by lighting the LED strip.

In connection with the touch screen display, the location of the specified container and tray can be intuitively recognized, reducing incorrect picking.

LED lights show the container to be unloaded.

We constantly listen to the issues warehouses face and develop additional functions to further improve their productivity.

When responding to such voices from logistics sites and market needs, we have for example introduced the Put to Light (mispick prevention) function.

Please contact us if you would like more information on implementation, costs, or would like to see a demonstration.

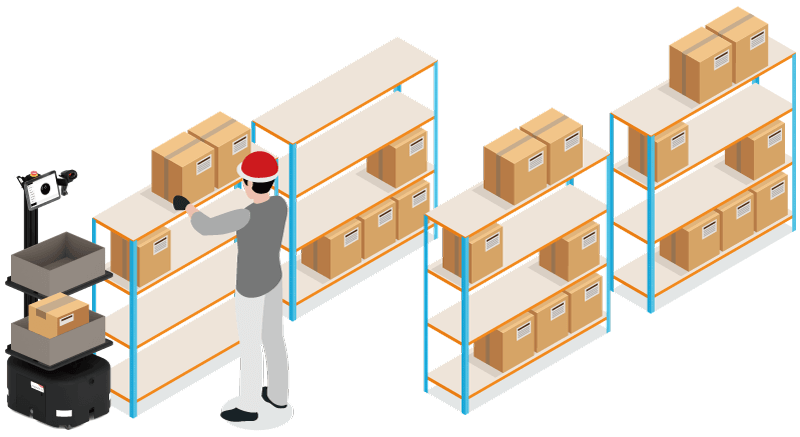

The Rapyuta PA-AMR is demonstrated at Rapyuta Robotics’ office. Shelves are arranged similar to a warehouse, allowing visitors to experience how picking is done.

| 1 | Presentation (introduction of our company and explanation of Rapyuta PA-AMR) | 30 min |

| 2 | Rapyuta PA-AMR Demonstration (Explanation of Rapyuta PA-AMR and picking demo) | 30 min |

| 3 | Q&A | 20 min |

When considering the introduction of the system, the simulator allows the expected effects of warehouse automation to be verified in advance. Using an actual on-site layout, the software used in the actual Rapyuta PA-AMR is executed in a virtual environment to achieve a high degree of institutional verification.

Japan India USA