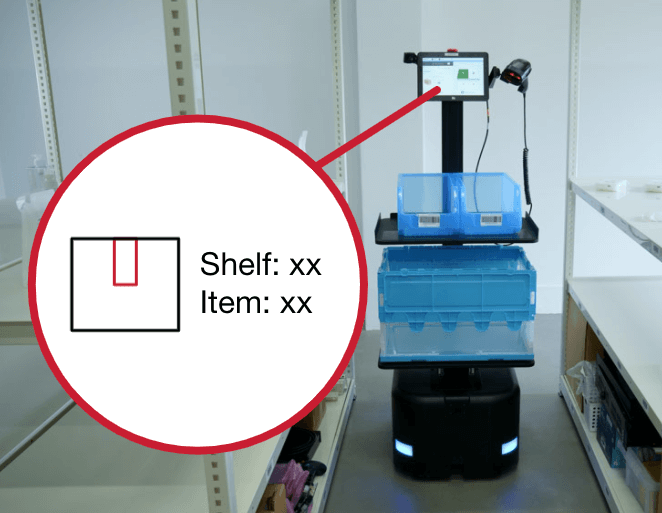

Based on the item size and order volume, container size is recommended.

| 10L container x 4 | 50L container x 2 |

|---|---|

| |

| Multi order picking for 4 orders can be handled. | Multi order picking for 2 orders, or batch picking can be handled. |

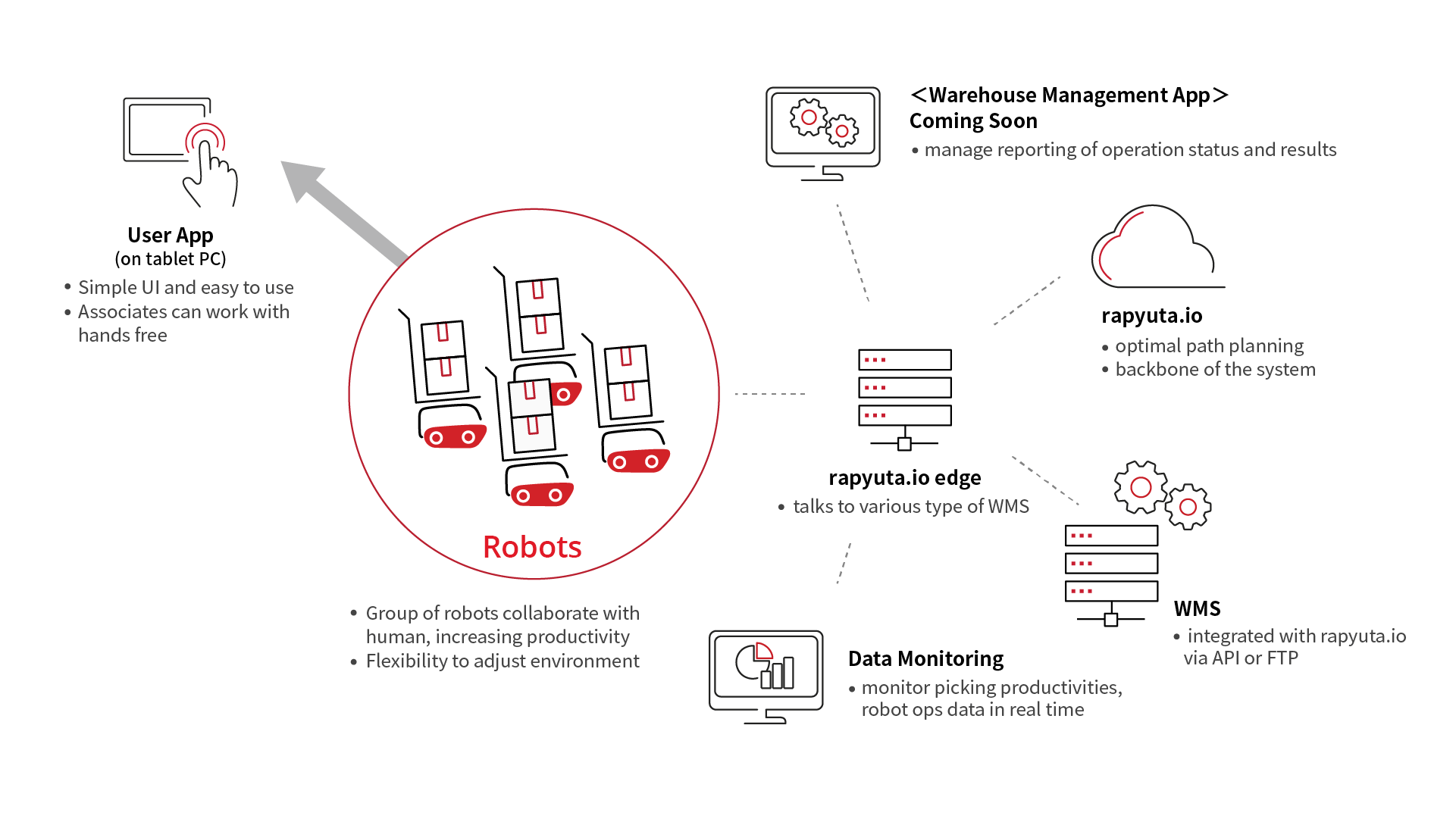

You can check the picking progress, AMRs device information, positions of all AMRs, and details of order information in one place. (Remote access is also possible)

Tablet mounted on AMR shows where to go next for the associates.

Note: You can use zone picking, if you wish.

During picking, various incidents happen such as item is missing or damaged.

Rapyuta PA-AMR has a robust error-handling process based on many user feedback. At the unloading point, you get notification if the container had a missing item and you can decide to keep the container until the missing item is collected or proceed with the available items, based on the warehouse policy or the situation.

Print out the documents required such as the packing list for inspection or the shipping label based on the request by the consignee.

During the busy season, you can run manual picking and AMR picking in parallel to increase the throughput.

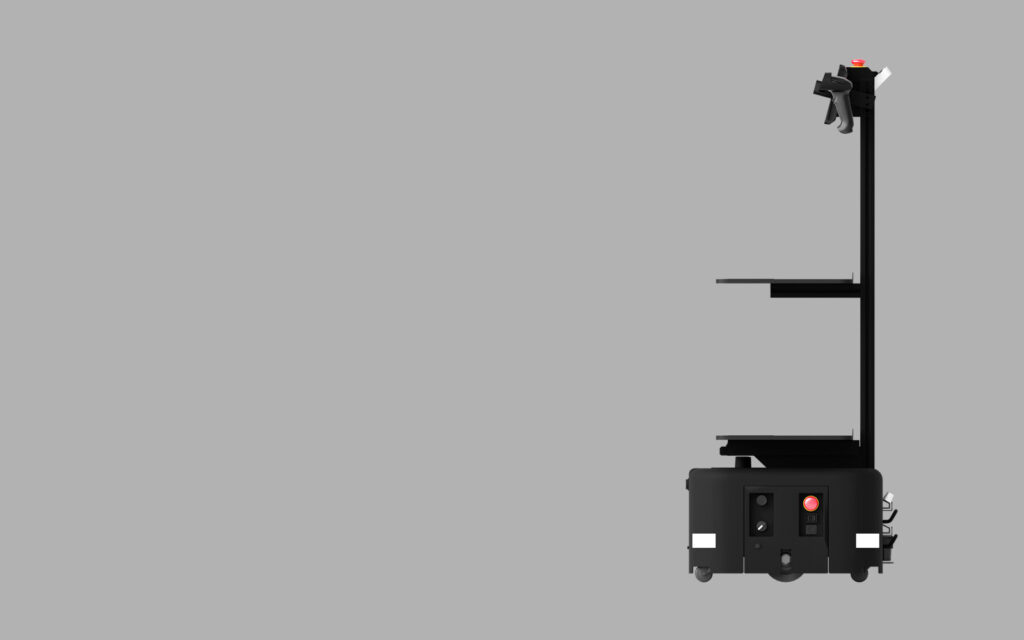

Safety is most important as AMRs work with people. Rapyuta PA-AMR has various sensors and emergency stop to ensure safety on all aspects.

For urgent orders, you can manually set the highest priority so that AMRs run to pick those orders first.

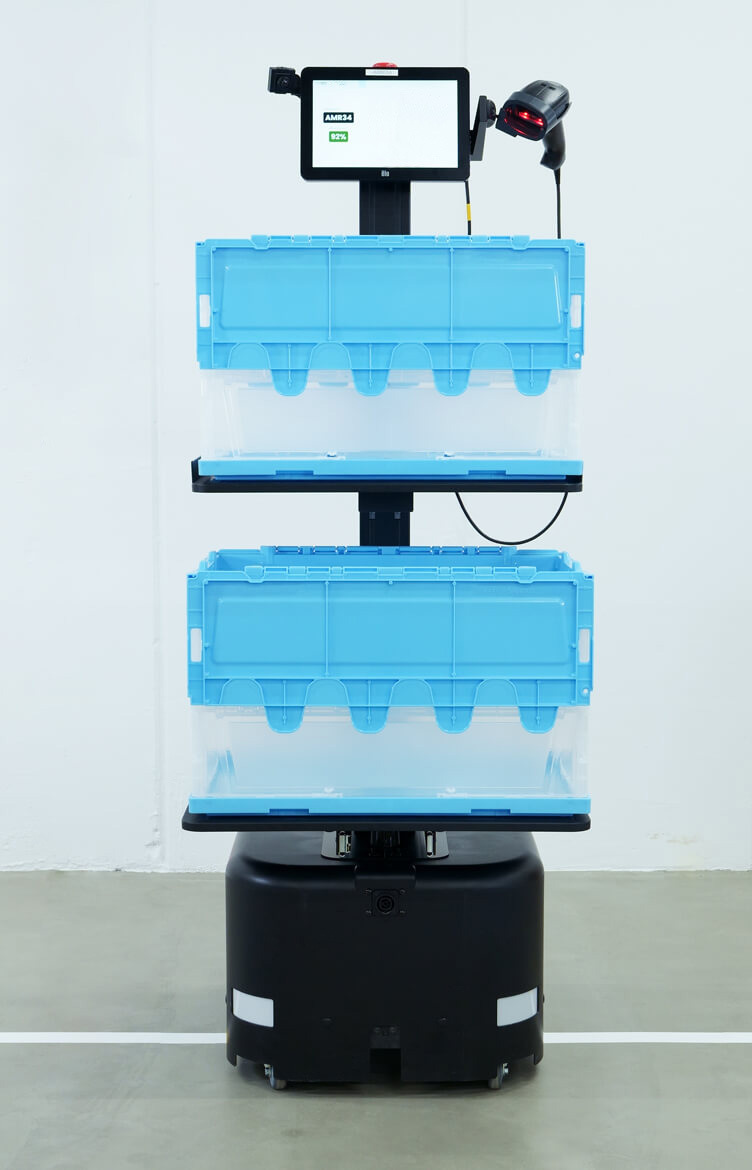

Touch Screen

Barcode Scanner

E-Stop

E-Stop

4 x Indication LED Lights

Patented retractable tray

Top Tray

Easily scan items with the rotatable barcode scanner and confirm the picked items using the touch screen. System can connect to edge PCs via WiFi and work with WMS.

Errors, charging status, etc. are indicated by LED lights. There are two emergency stop buttons on the top and bottom, allowing one to easily stop the robot.

The height of the top tray can be adjusted and it is also removable. Size of the tray can also be customized.

Both the driving and caster wheels are AGV wheels. The motor and suspension have also been adjusted, making movement smooth and quiet.

Localization with an accuracy of 10-15 cm. Two 3D cameras working in tandem for obstacle avoidance.

No need to read barcodes thus making picking easier. Can also be linked with other RFID devices.

A docking station for automatic charging. Easy charging in large warehouses. Automatically execute charging at optimal schedules.

The Rapyuta PA-AMR is demonstrated at Rapyuta Robotics’ office. Shelves are arranged similar to a warehouse, allowing visitors to experience how picking is done.

| 1 | Presentation (introduction of our company and explanation of Rapyuta PA-AMR) | 30 min |

| 2 | Rapyuta PA-AMR Demonstration (Explanation of Rapyuta PA-AMR and picking demo) | 30 min |

| 3 | Q&A | 20 min |

When considering the introduction of the system, the simulator allows the expected effects of warehouse automation to be verified in advance. Using an actual on-site layout, the software used in the actual Rapyuta PA-AMR is executed in a virtual environment to achieve a high degree of institutional verification.

Japan India USA