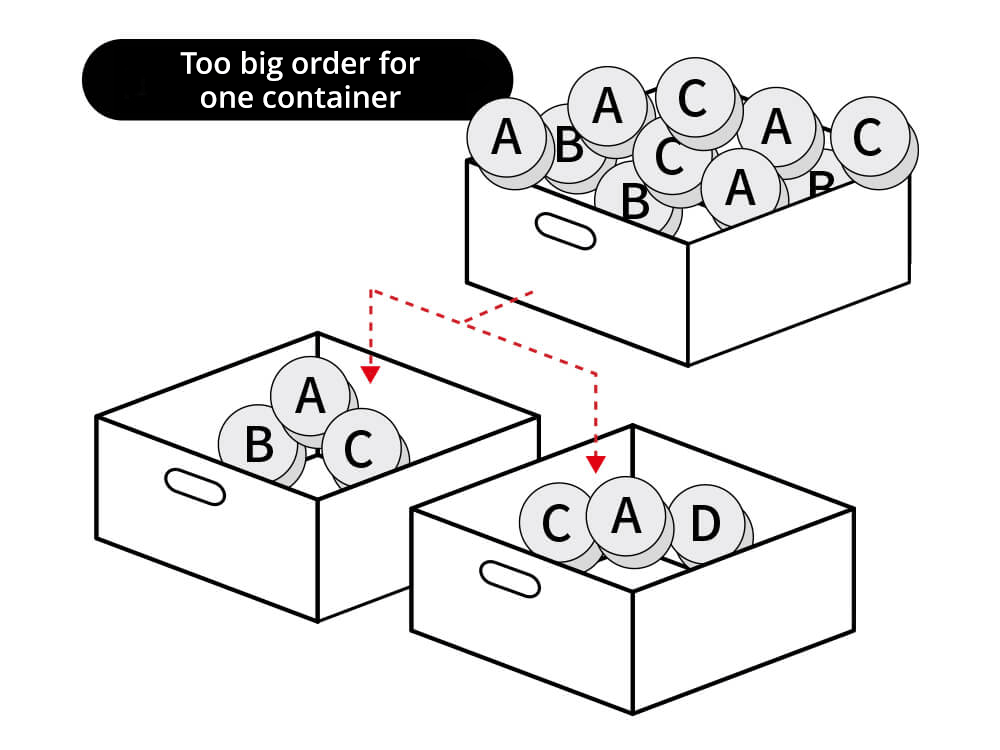

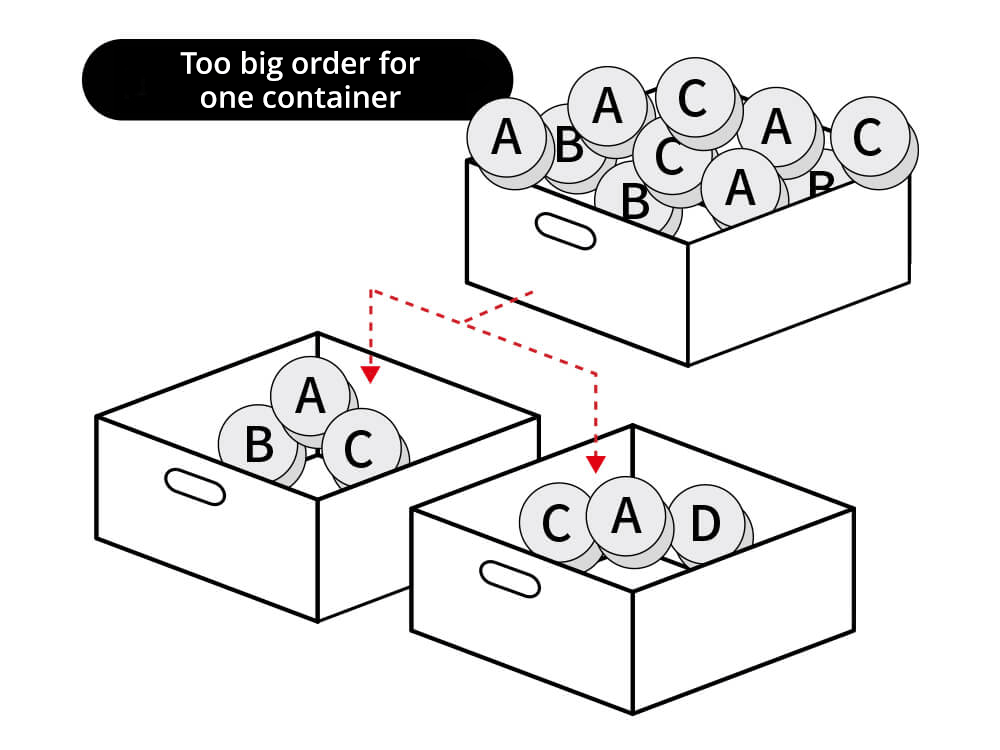

If one order does not fit into one container, the order is split into multiple containers. With WMS integration, our system keeps the item volume and size below the target threshold.

In addition to various container sizes, you can put cardboard partitions.

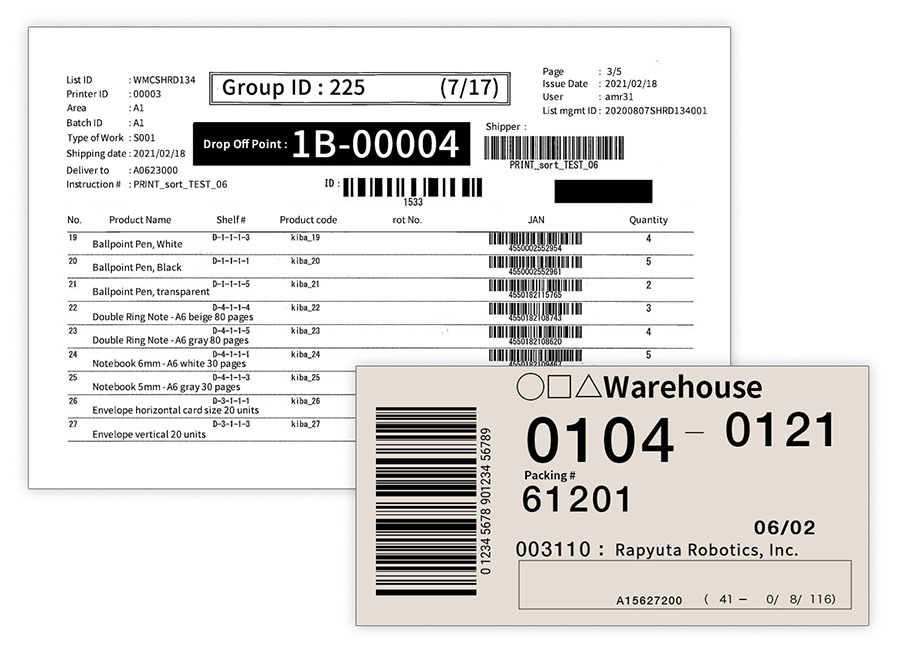

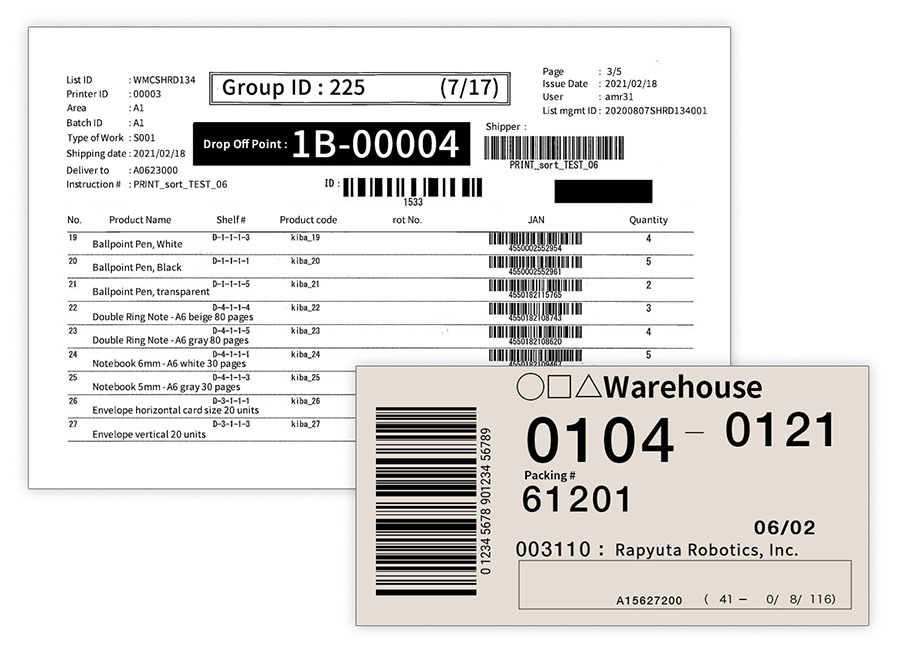

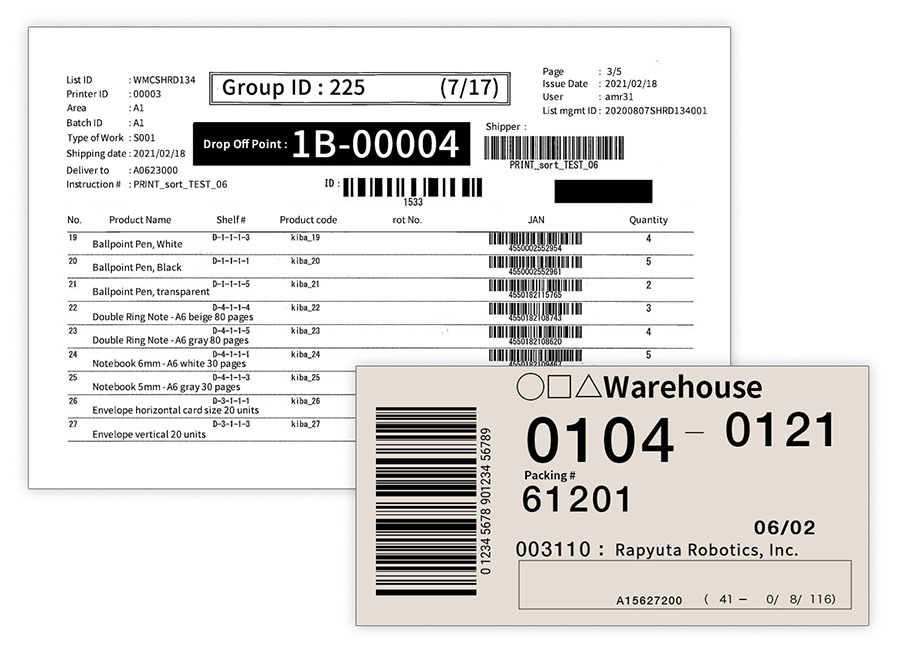

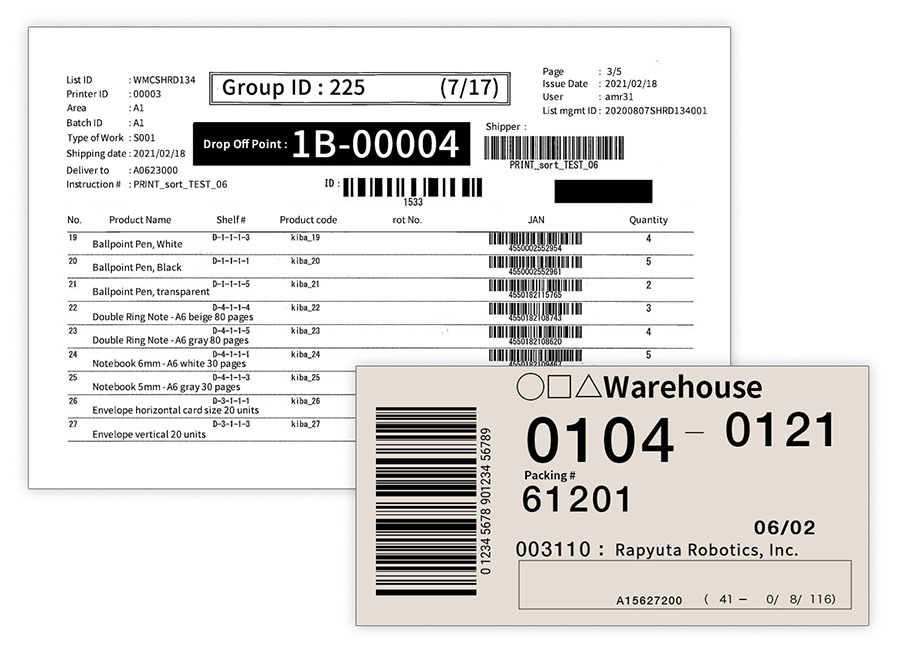

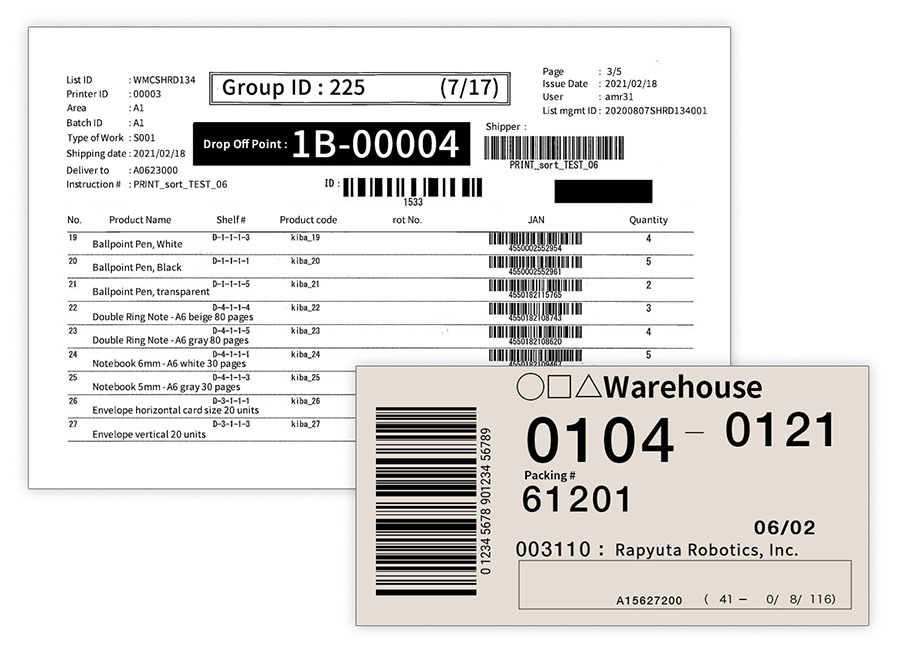

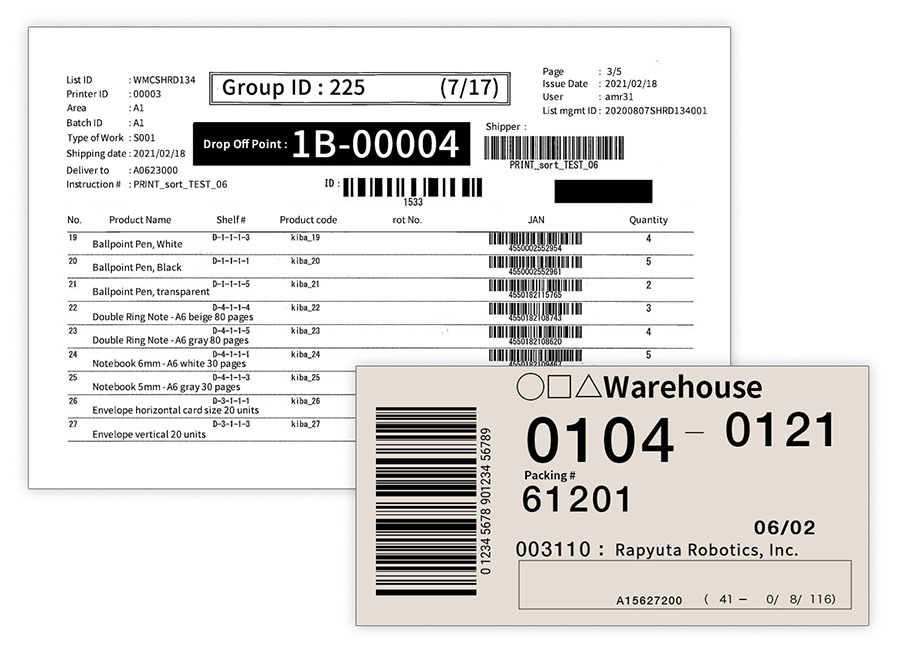

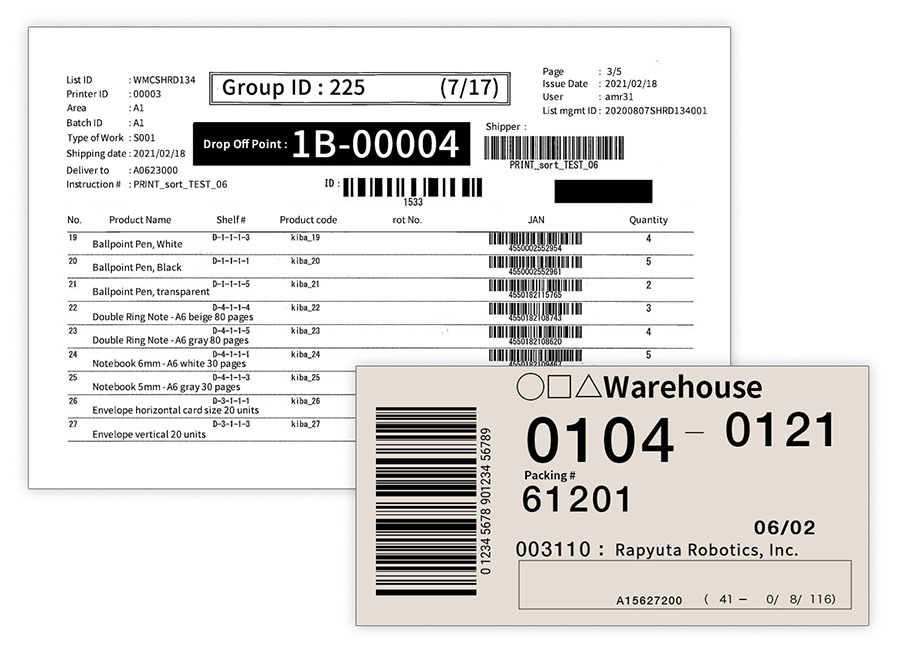

A Shipping label and packing list can be printed on paper or stickers to accomodate requests from the consignee.

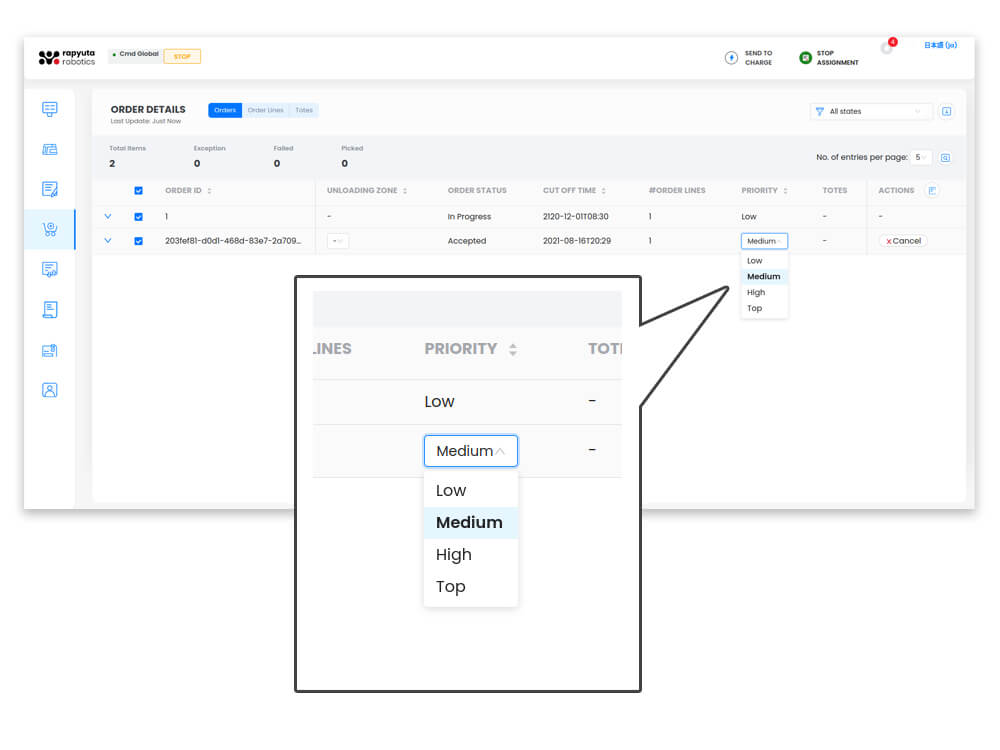

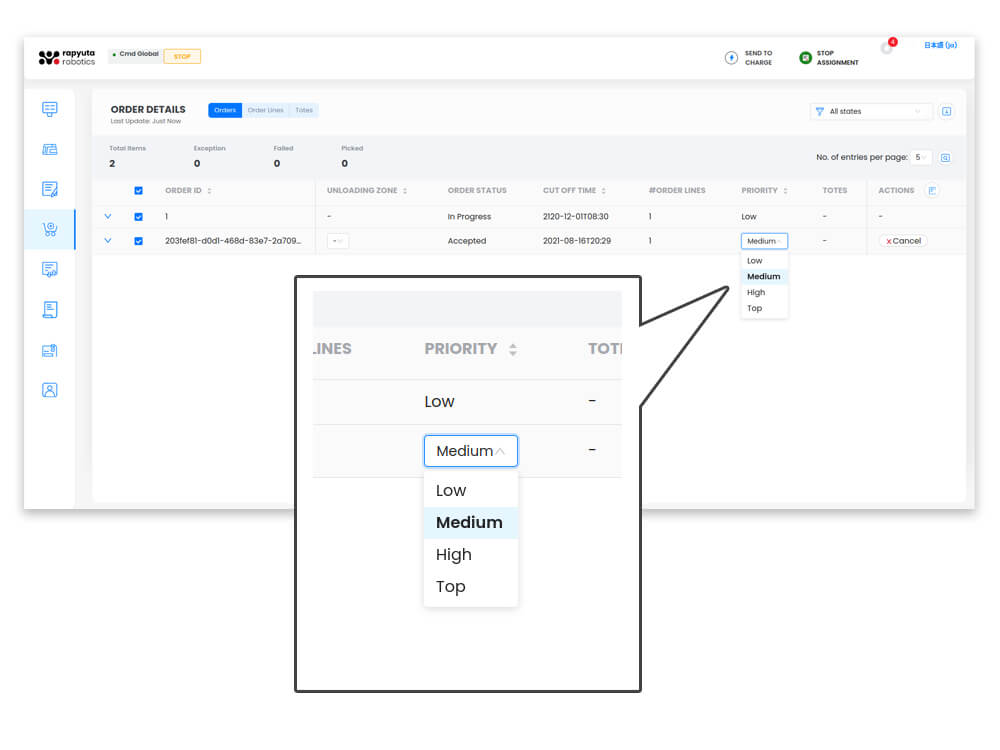

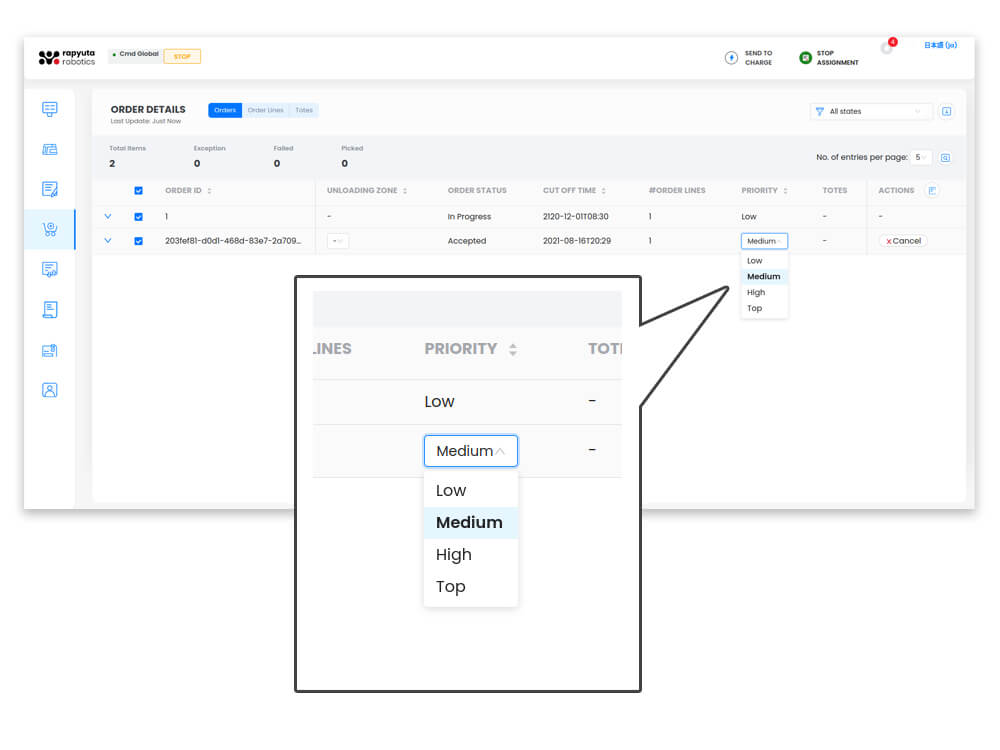

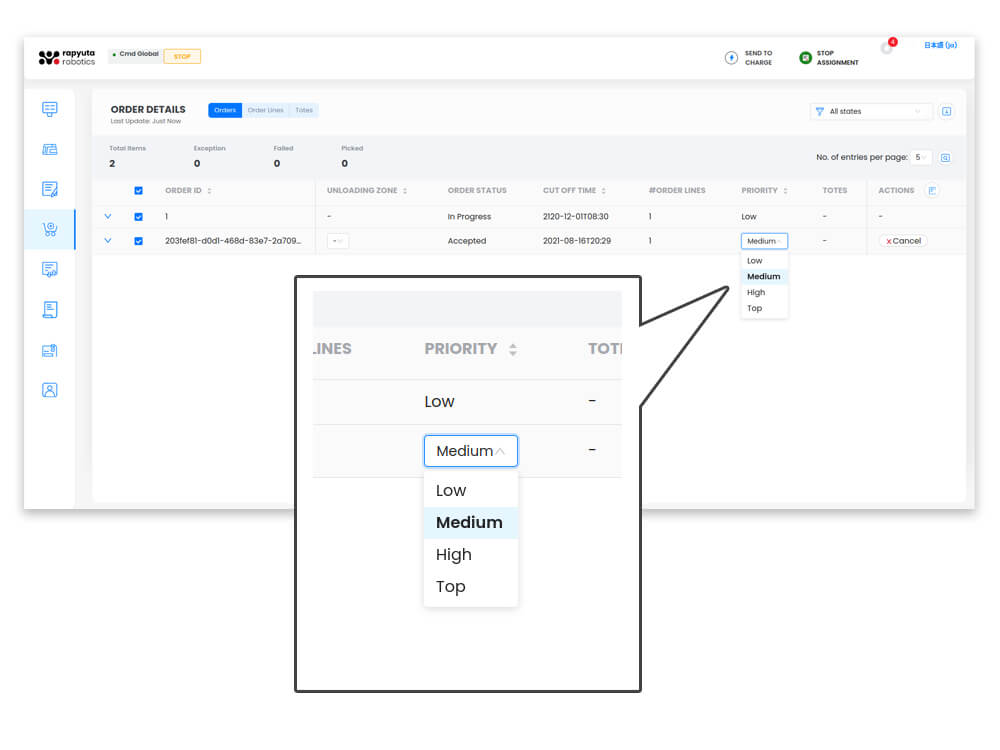

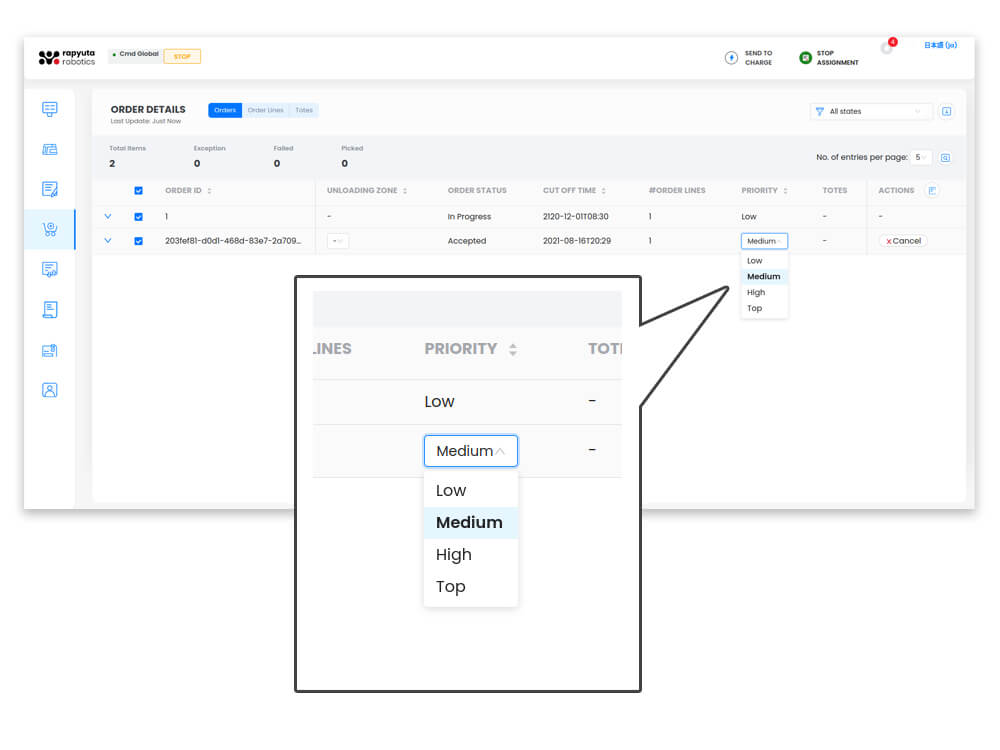

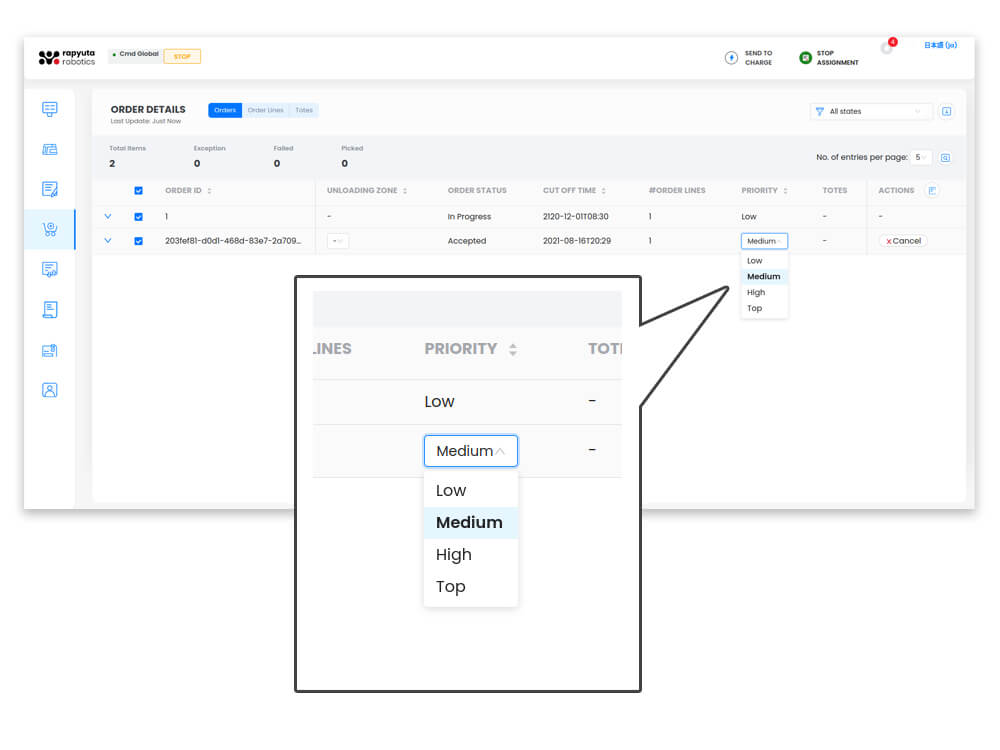

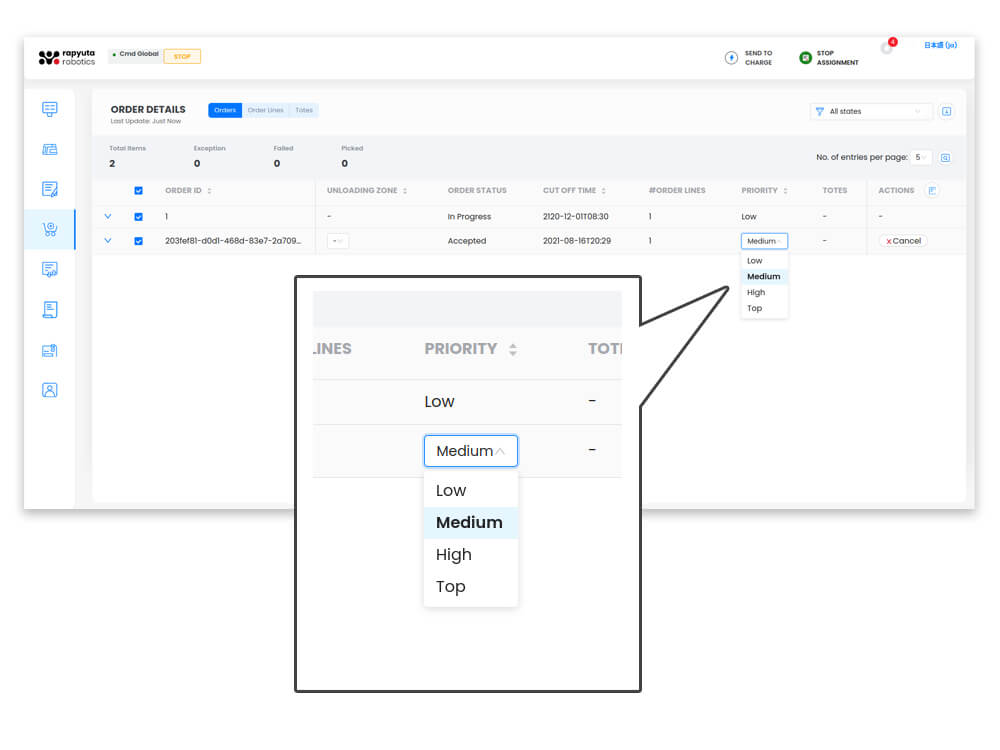

By setting the high priority, you can handle urgent orders ahead of others.

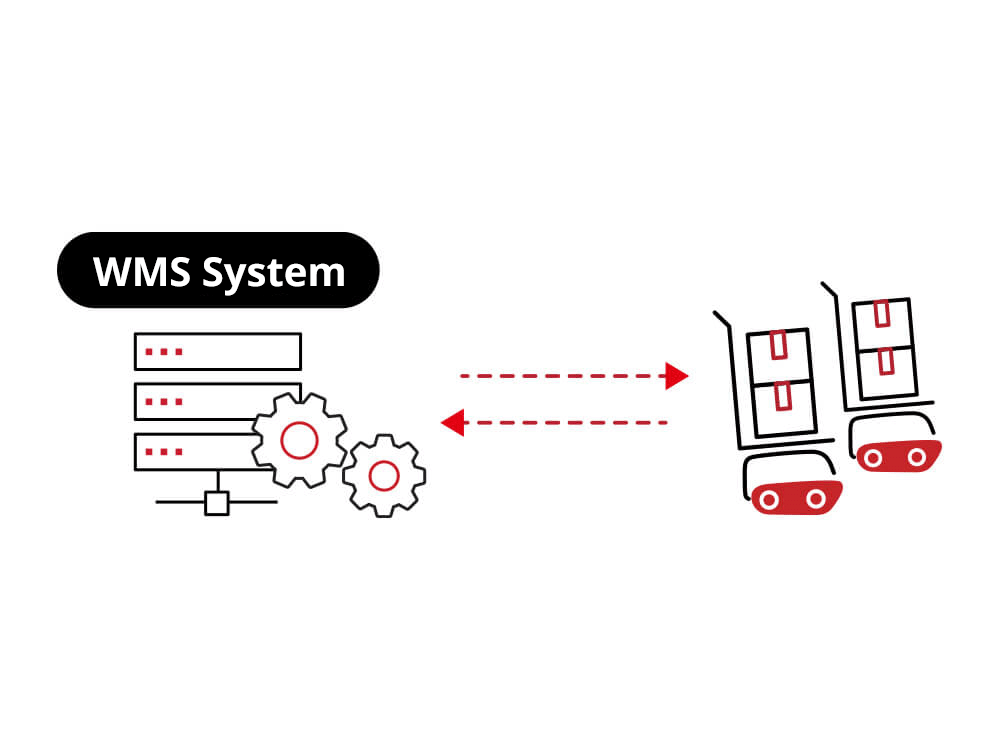

With the integration, our system can seamlessly handle product turnover (and free location system).

In addition to various container sizes, you can put cardboard partitions.

A Shipping label and packing list can be printed on paper or stickers to accommodate requests from the consignee.

To increase throughput, you can:

Picker guidance system offers most optimal path.

You can put the items to the shelf for returned goods.

Text

Text

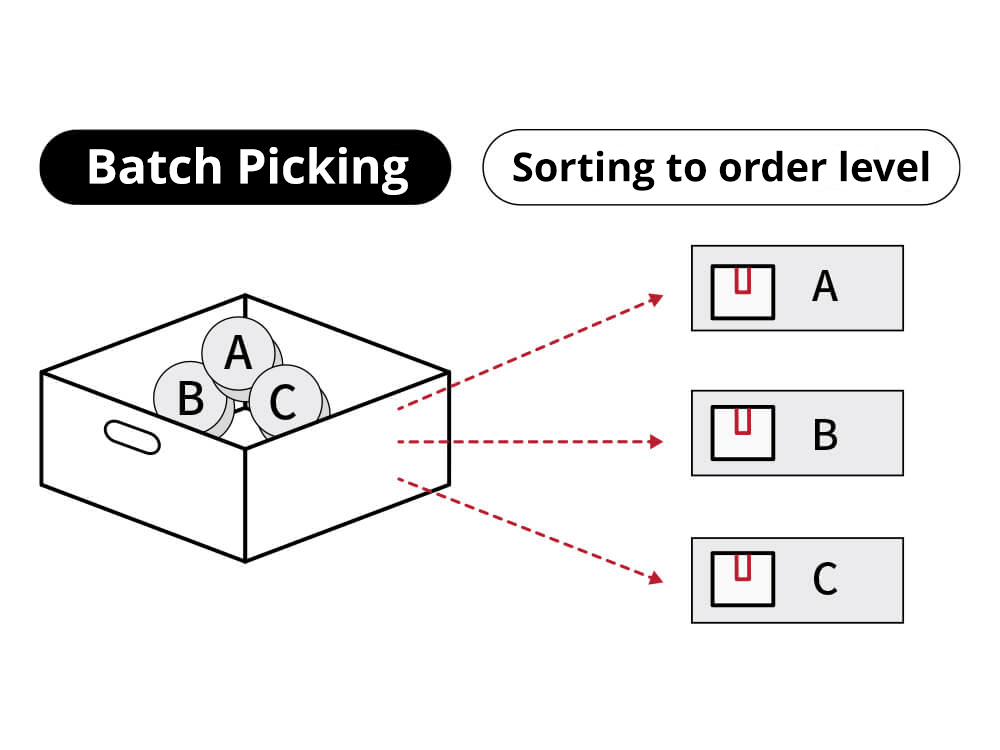

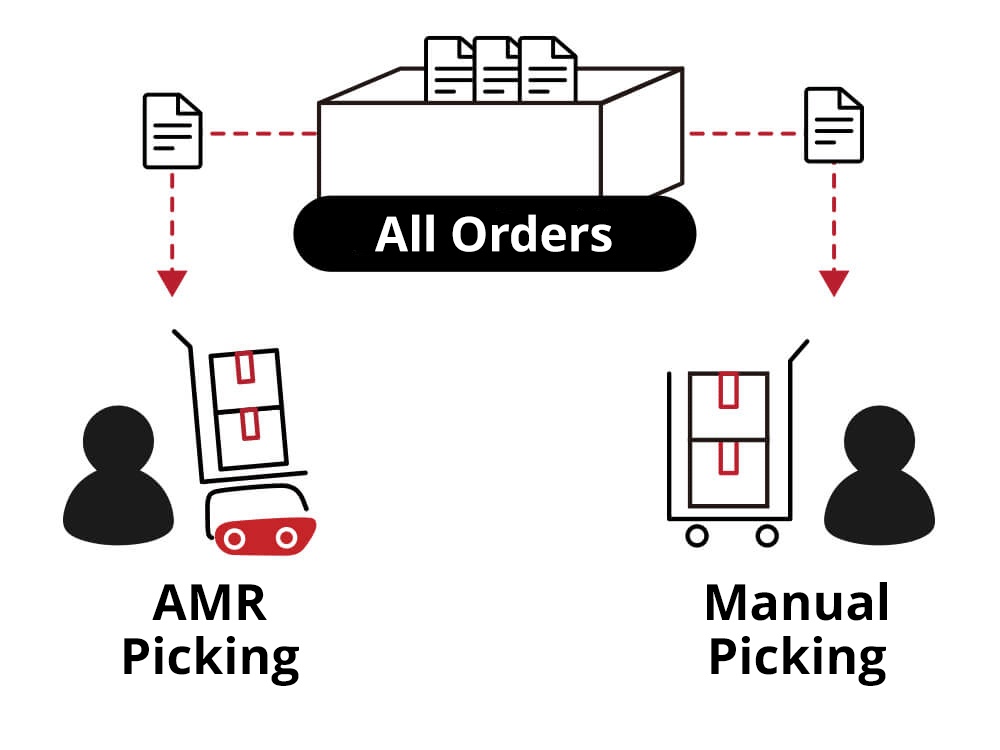

Our AMR can handle batch picking in addition to order picking.

In addition to various container sizes, you can put cardboard partitions.

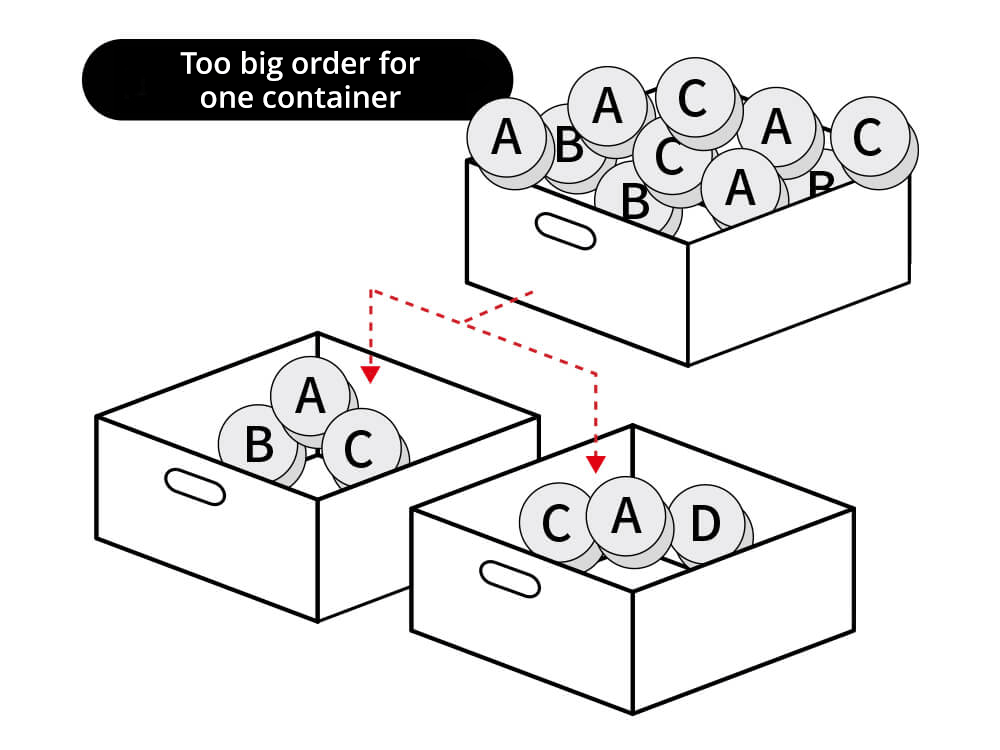

If one order does not fit into one container, the order is split into multiple containers. With WMS integration, our system keeps the item volume and size below the target threshold.

By setting the high priority, you can handle urgent orders ahead of others.

A Shipping label and packing list can be printed on paper or stickers to accommodate requests from the consignee.

If the items do not have a barcode, you can add it with labeler (additional charge is applied).

Text

Text

Based on the item size and weight, appropriate order will be assigned to AMR picking.

To ensure high picking accuracy, you can integrate AMRs with RFID and weighing equipments (additional charge is applied).

If one order does not fit into one container, the order is split into multiple containers. With WMS integration, our system keeps the item volume and size below the target threshold.

By setting the high priority, you can handle urgent orders ahead of others.

If the items do not have a barcode, you can add it with labeler (additional charge is needed).

Text

Text

Text

With the integration, our system can seamlessly handle product turnover (and free location system)

In addition to various container sizes, you can put cardboard partitions.

If the warehouse layout changes, the map can be updated quickly.

By checking the progress of the order picking, you can allocate optimal # of associates.

Even the new associate can use AMRs easily. With the short training, warehouse manager can quickly increase throughput.

A Shipping label and packing list can be printed on paper or stickers to accommodate requests from the consignee.

Text

Text

The Rapyuta PA-AMR is demonstrated at Rapyuta Robotics’ office. Shelves are arranged similar to a warehouse, allowing visitors to experience how picking is done.

| 1 | Presentation (introduction of our company and explanation of Rapyuta PA-AMR) | 30 min |

| 2 | Rapyuta PA-AMR Demonstration (Explanation of Rapyuta PA-AMR and picking demo) | 30 min |

| 3 | Q&A | 20 min |

When considering the introduction of the system, the simulator allows the expected effects of warehouse automation to be verified in advance. Using an actual on-site layout, the software used in the actual Rapyuta PA-AMR is executed in a virtual environment to achieve a high degree of institutional verification.

Japan India USA