Rapyuta ASRS offers extensive customization to meet your specific requirements. Learn the system’s core features and the challenges that we can resolve for you.

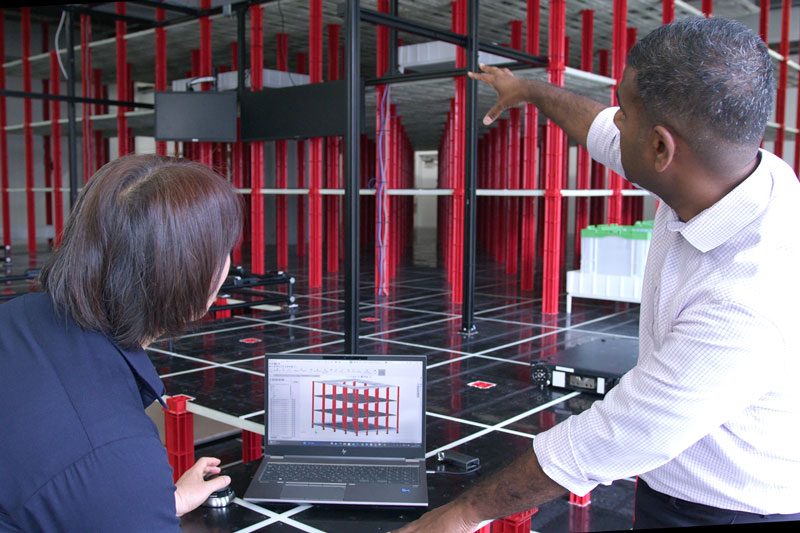

Rapyuta ASRS is a system comprised of robots utilizing multi-robot control AI technology, FRP (Fiber Reinforced Plastic) structures, and other advanced components. Discover how each feature brings innovation to your warehouse operations.

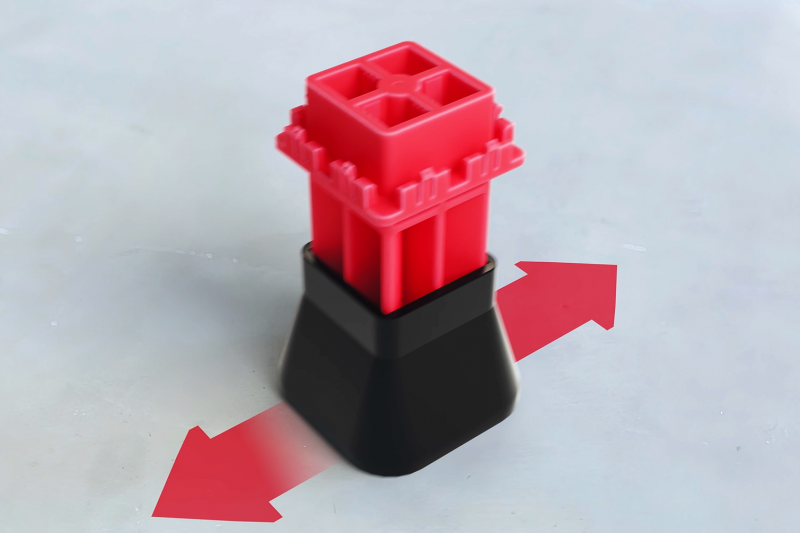

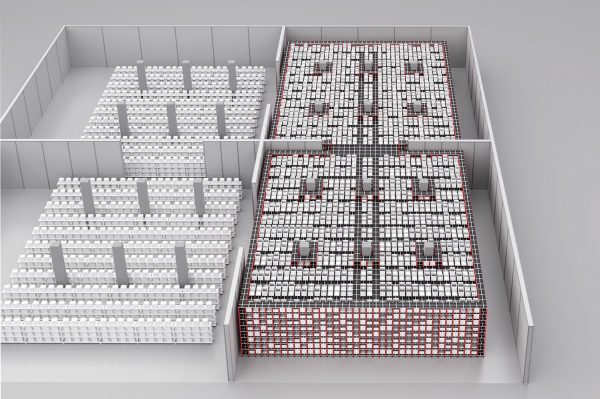

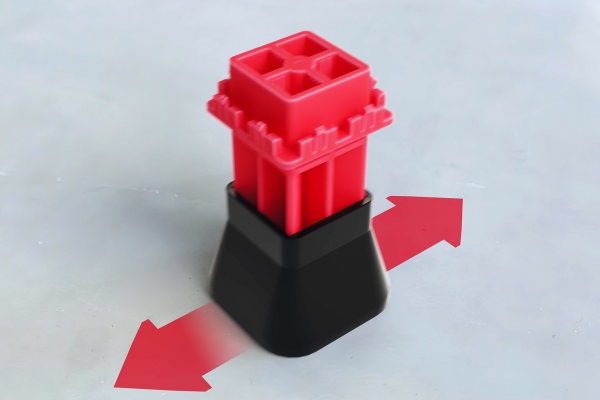

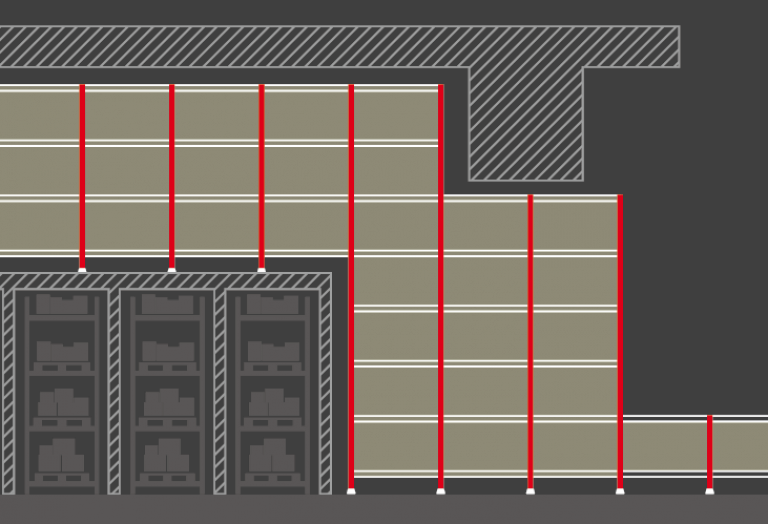

The structure of Rapyuta ASRS is based on modular units composed of three main components: the Base Block, Pole, and Floor Panel. These modules can be arranged freely to fit the layout of your site, much like assembling building blocks.

The modular design of Rapyuta ASRS eliminates the need for anchors. Its base structure is engineered to absorb vibrations during earthquakes and allows for easy relocation with minimal effort when needed.

The system includes equipment such as Picking Stations, Lifts, and Charging Stations. Their locations and quantities are tailored to meet your specific requirements for performance.

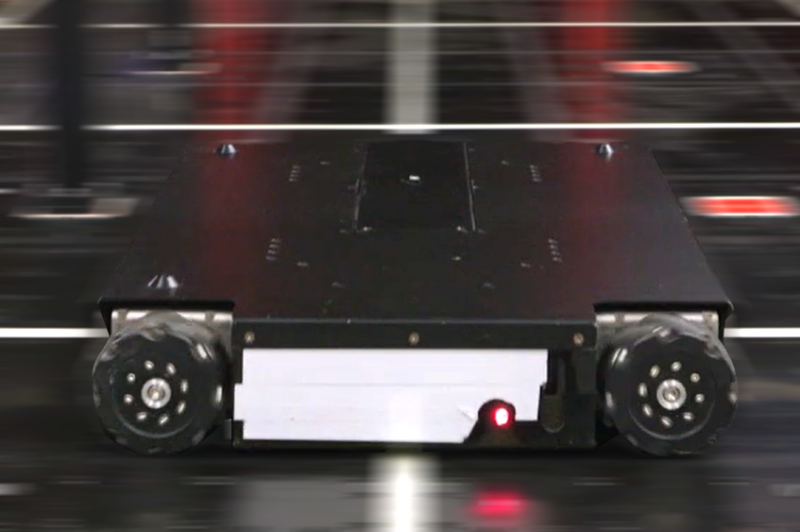

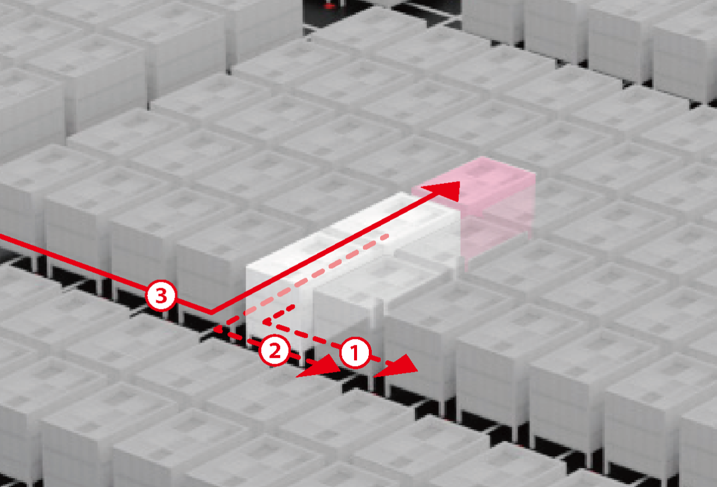

Rapyuta ASRS robots can access every space on every floor. With no movement restrictions horizontally or vertically, they can quickly and directly reach the target bin, no matter where it’s located, and deliver it swiftly.

The robots run at speeds of up to 2.5 meters/sec (8.2 feet/sec). With the ability to access every space across levels, the fleet control system ensures that the robots cooperate efficiently, run along optimized routes at high speed to swiftly deliver bins.

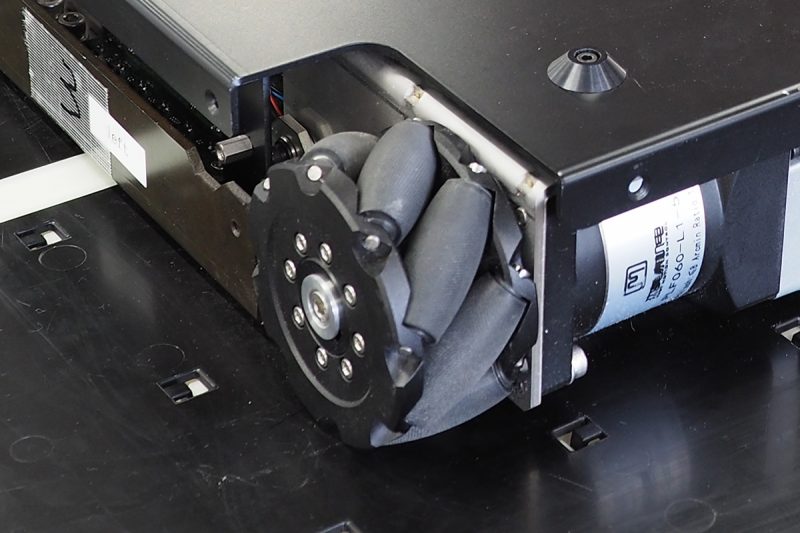

Rapyuta ASRS robots utilize mecanum (tireless omnidirectional) wheels, enabling smooth movement in any direction without the need to pause for turns. This design not only enhances the robots’ speed but also significantly boosts productivity across all operations.

Rapyuta Robotics’ multi-robot control and coordination AI, a key strength of our company, has been proven to manage up to 300 robots. This technology not only handles a large number of robots, but also ensures they collaborate across different levels and positions within the ASRS to execute tasks optimally, consistently maintaining high productivity.

Movement between floors within the ASRS is facilitated by high-speed lifts. The location of bins within the ASRS is automatically adjusted based on the shipping frequency of the SKUs in each bin. When picking items stored on different floors, the robots collaborate across levels to ensure optimal operations.

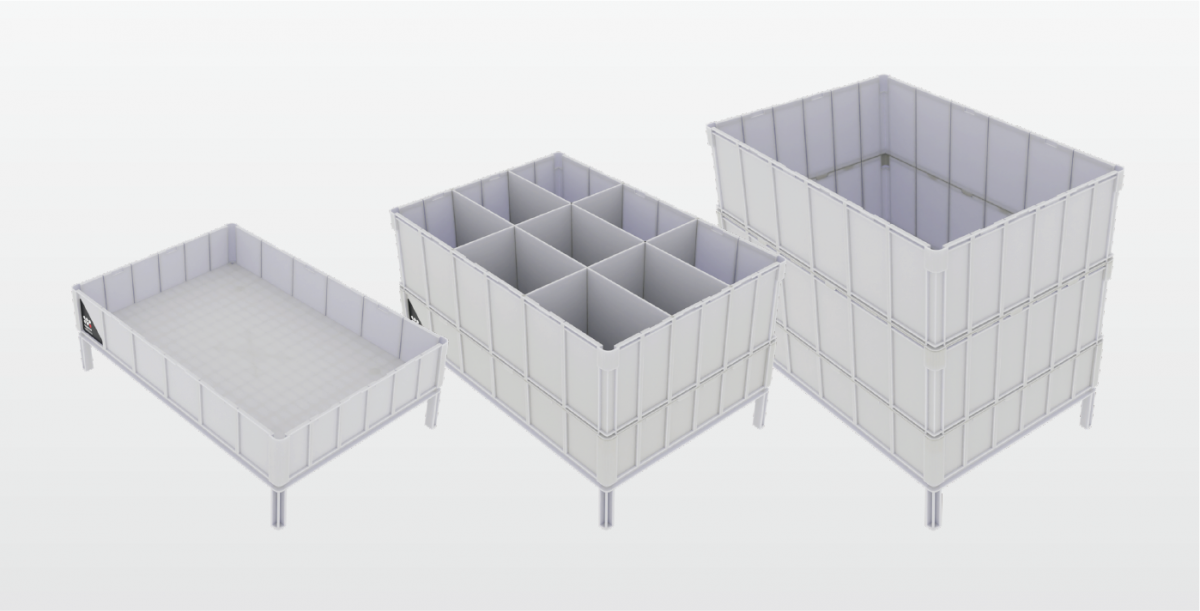

The bins come in three height variations to accommodate different item sizes. Additionally, partitions can be added to each bin, allowing for the storage and management of multiple SKUs within a single bin.

Bin sizes: W25.6 x D17.3 x H 8.6 / 15.7 / 22.8 inch (W65 x D44 x H22 / 40 / 58 cm).

Bins can also be used with folding containers or cardboard boxes. For example, it is common to use folding containers on shipping bins as returnable containers. Our experts can suggest the best ways to maximize productivity.

Rapyuta ASRS allows for flexible layouts that maximize space utilization in various settings, including upper floors of warehouses where anchor installation is challenging, rental warehouses, and locations with columns and beams. It is also ideal for installation on the first floor and mezzanine. No matter the configuration, our solution adapts to your needs.

While there are other automated storage systems that can scale as your business grows, Rapyuta ASRS stands out because it does not require halting warehouse operations during expansion projects. This advantage also applies when introducing the ASRS into an existing, operational warehouse. Our system is the most scalable solution available in the market.

Rapyuta ASRS, which eliminates the need for anchor installation, can be relocated to other sites with minimal cost and time. In today’s VUCA (Volatile, Uncertain, Complex, and Ambiguous) world, it’s challenging to predict external changes even a few years ahead. As the only truly adaptive ASRS, Rapyuta ASRS ensures your profitability, no matter how quickly the landscape changes.

At Rapyuta Robotics, we believe that robots are here to enhance human work, not replace it. By taking on heavy, dirty, and dangerous tasks, our robots help make people’s lives better. With Rapyuta ASRS, humans and robots collaborate seamlessly to maintain consistently high productivity.

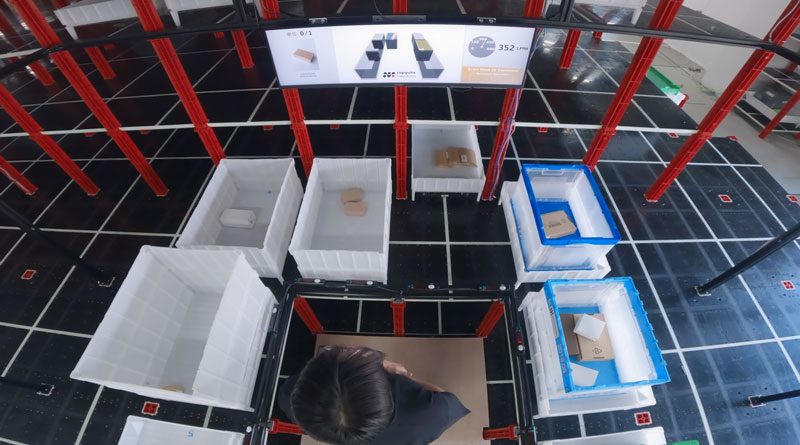

In warehouse picking operations, over 70% of the time is said to be spent walking. With Rapyuta ASRS, like other automated storage systems, robots eliminate walking time through Goods-to-Person picking.

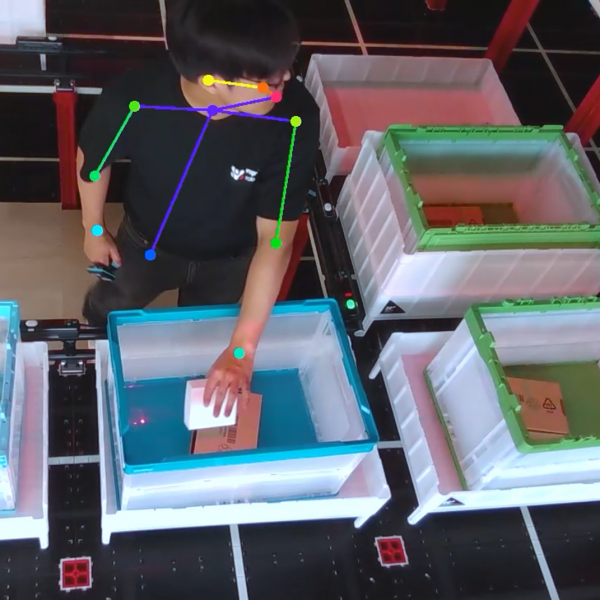

Additionally, our unique surrounding design allows for concentrated work on up to eight bins simultaneously. Displays, projectors, and motion capture cameras at the picking station visually guide workers, minimizing errors regardless of age, language, or skill level. This ensures anyone can perform picking tasks efficiently and accurately.

Many robots need downtime for battery charging, but Rapyuta Robotics’ automated storage and retrieval system prevents this by swapping out batteries instead. The automated battery exchange takes less than a minute, maximizing robot uptime. After the swap, the batteries are automatically charged at the Charging Station, ready for the next use.

Rapyuta ASRS supports sequential shipping as a standard feature. After picking is complete, the bins for shipment are collected in a temporary storage area and then dropped off in the specified order at the designated time. This allows for efficient loading of trucks in the correct sequence and streamlines freight consolidation tasks.

The robots can run through under bins to reach the target bin. Then lift up the bin to handle it to the destination. Rapyuta ASRS has multiple floors as >7 layers and the robots access anywhere on any floor.

The robots can run through under bins to reach the target bin. Then lift up the bin to handle it to the destination. Rapyuta ASRS has multiple floors as >7 layers and the robots access anywhere on any floor.

Rapyuta ASRS can be assembled like block toys, perfectly fitting into existing warehouses with complex layouts, including columns, beams, and mezzanines. This flexibility allows you to maximize space utilization in any warehouse configuration.

Most ASRS require aisles for robots. However, with Rapyuta ASRS, bins can be densely packed in multiple rows. Thanks to our fleet control technology, multiple robots can work together to temporarily remove front bins, allowing another robot to access the target bin. This approach significantly improves storage efficiency.

In Rapyuta ASRS, each floor’s height is determined by 24.8inch (63 cm) Poles, but we also offer 20.8inch (53 cm) of Short Poles. When dealing with small items like parts, stationery, or books, using Short Poles allows for more levels, maximizing space efficiency. We recommend this option for optimizing your storage space when applicable.

Since the end of the pandemic, many companies have been grappling with labor shortages. To cope, they are automating as many tasks as possible, freeing up human resources for more valuable work. Rapyuta ASRS supports this by letting robots handle tasks they’re best at, while humans take on the more complex and difficult-to-automate tasks, creating a human-friendly automation environment.

Complex tasks and those requiring speed are areas where humans excel over robots. In warehouse operations, tasks like picking, inspection, packaging, and value-added services cannot be fully automated without significant investment. Therefore, it is generally better to focus on improving the efficiency and accuracy of human workers.

By assigning personnel to more valuable tasks and improving their efficiency while preventing errors, you can enhance the quality of warehouse operations and reduce the extra time and costs spent on error recovery. Meeting schedules and maintaining high-quality work also helps build greater trust with your customers.

Although it’s rarely discussed, the costs, time, and energy required for recruiting on-site workers are substantial. These factors are often overlooked in ROI calculations for automation. However, users of Rapyuta Robotics products can also minimize these hidden costs.

The display at the picking station provides a visual guide showing the item to be picked, the quantity, and which bin to move the item from and to. This system allows anyone, regardless of language, to intuitively perform picking tasks quite easily.

The picking station features two motion capture cameras that track the worker’s movements. If the worker reaches for the wrong bin or scans the incorrect item, an alert sound and red light will notify them, prompting the correct action and ensuring accuracy.

After completing each picking task, the worker needs to press the Finish Button in front of the shipping bin to complete it. If the motion capture system detects an incorrect pick, the Finish Button will not respond. This triple error prevention system ensures that anyone can work easily and accurately without mistakes.

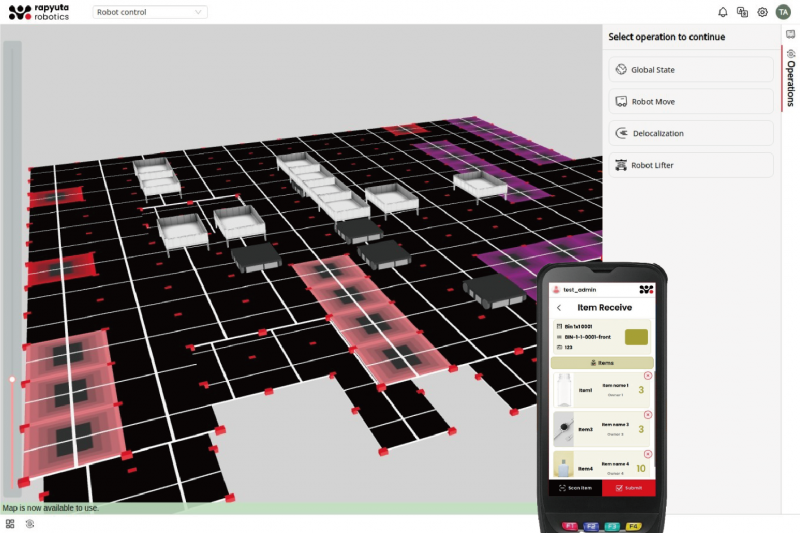

With the software and free WMS of Rapyuta ASRS, you can intuitively understand how to operate in the desktop and handy terminal screen instantly. Also, the WMS can be integrated with your operational system via API so you can seamlessly work with the system.

Rapyuta ASRS’s WMS can integrate with other systems, including your existing WMS, through API connections. It can connect not only with major third-party systems but also, in most cases, with your specific systems as well.

Rapyuta Robotics also offers regular maintenance services after installation. For example, if your operations change between peak and off-peak seasons, our maintenance service can switch the robot control programs to suit either busy or slow periods.

The modular design structure that makes the Rapyuta ASRS the only adaptive ASRS.

Having troubles selecting automated storage or warehouse automation solutions? We can help you clarify requirements and choose the solution that best fits your warehouse.

Japan India USA