10x Productivity and 2.5x Storage Efficiency for Your Warehouse.

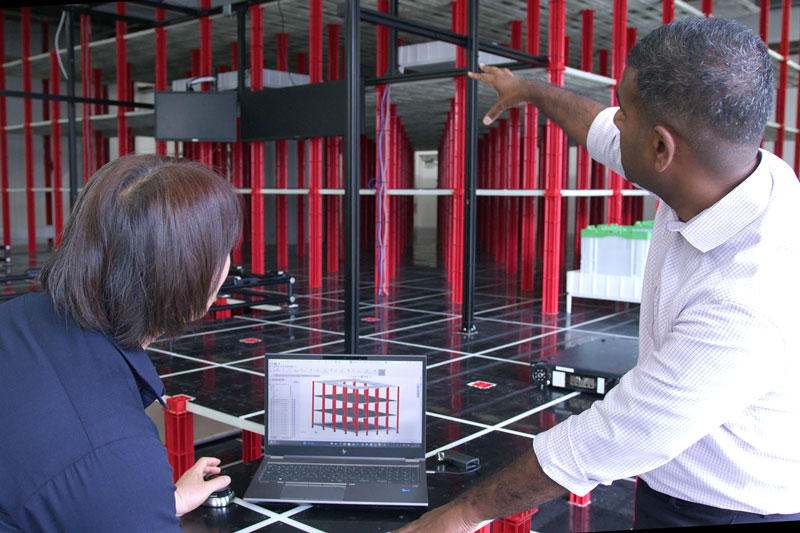

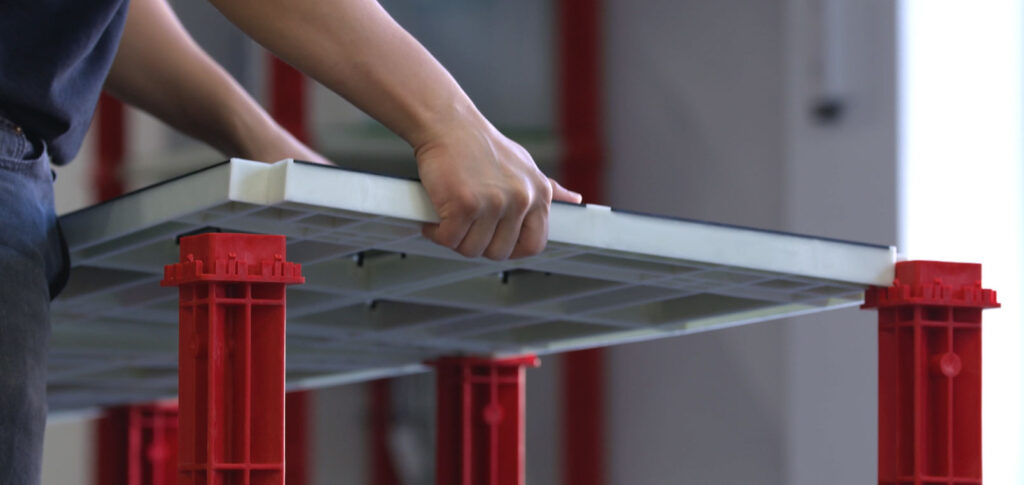

Rapyuta ASRS offers modular-type assembly, providing remarkable flexibility in terms of robot quantity, storage density, and configurations even for existing warehouses.

10x Productivity and 2.5x Storage Efficiency for Your Warehouse.

Rapyuta ASRS offers modular-type assembly, providing remarkable flexibility in terms of robot quantity, storage density, and configurations even for existing warehouses.

Possible to fit warehouses of any layout, to scale as your business grows. Easily moved if you need to relocate.

The multi-robot control and coordination technology powered by AI enables communication between robots to achieve maximum throughput.

The anchorless structure and flexible layout brought by modular design makes it possible to install Rapyuta ASRS at any space in any warehouses.

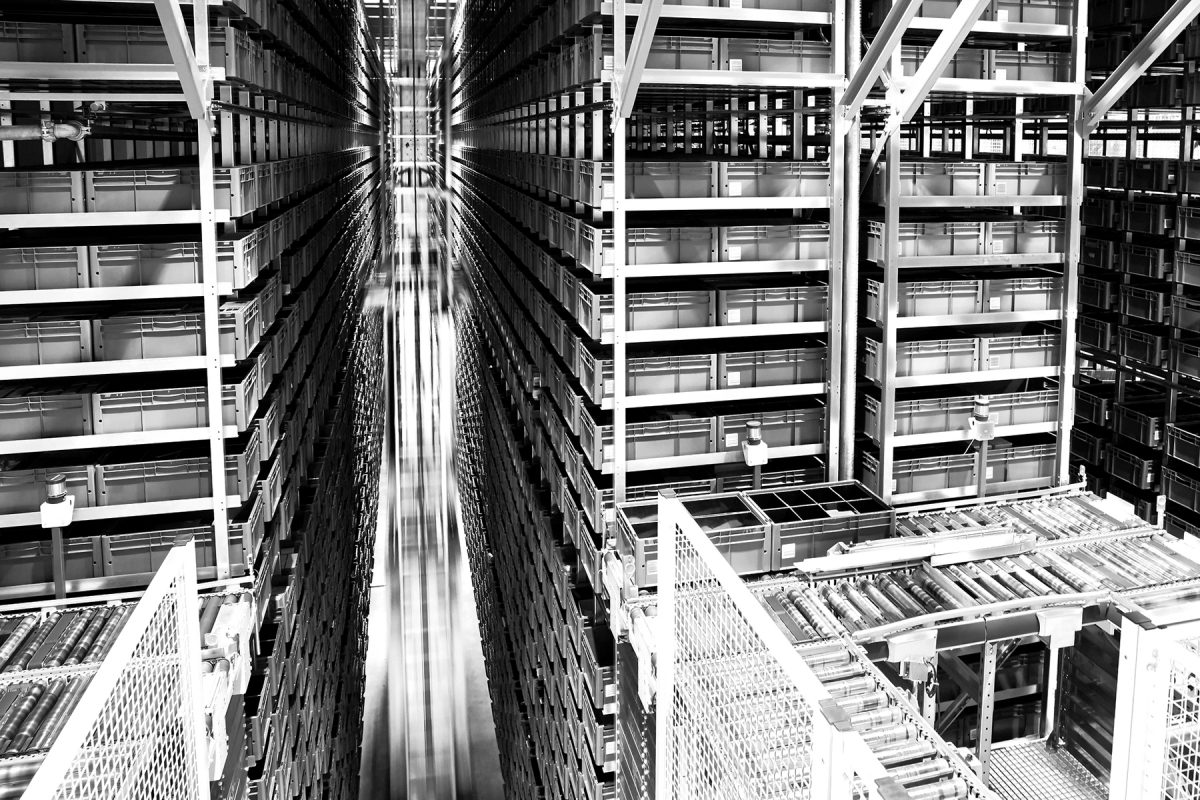

The main advantages of a typical automated storage and retrieval system are maximizing storage efficiency, including vertical space, and enhancing productivity. Many solutions significantly improve one of these aspects, but compromise on the others.

Raputa ASRS is designed to dramatically enhance both storage efficiency and productivity. There’s no longer a need to compromise on your solution.

With its anchorless structure and modular design, the Rapyuta ASRS allows for flexible layouts, making it easy to scale the ASRS as your business grows. Additionally, in these rapidly changing times, it can be relocated to other sites in the future, offering adaptability for years to come.

To consistently achieve high performance, it is essential to balance high storage efficiency with productivity. The Rapyuta ASRS features the industry’s thinnest robots, which, powered by multi-robot control AI , can access and collaborate across all floors and spaces, maximizing productivity.

AGVs and AMRs are commonly chosen to support picking operations. AGVs primarily handle point-to-point transport, while AMRs can adapt their routes and sequences on the fly. While these robots offer significant benefits in smaller warehouses, for spaces over 5,000 square feet, the Rapyuta ASRS can provide substantial improvements. By optimizing vertical space and reducing aisle space, storage efficiency is greatly enhanced, and productivity is boosted by minimizing walking time during picking operations.

Shelf-To-Person Robots are relatively inexpensive and can reduce walking time for picking operations. However, since they transport entire shelves, there are limitations in transport speed and productivity, especially when picking from the same shelf in quick succession at multiple picking stations. They also have constraints in optimizing vertical space efficiency and require bigger space for aisles. With the Rapyuta ASRS, each robot transports a single bin, maximizing productivity and storage efficiency by requiring minimal aisles and unlocking full vertical space.

In the ACR system, while aisle space is sacrificed, vertical storage efficiency is significantly improved. Typically, during picking operations, a mechanical station receives cases from the robot shelves and transfers them to a conveyor for line-style picking. The factors affecting productivity include the time it takes for robots to move to each case location, the time required to retrieve the cases, and the time needed to unload at the picking station. In contrast, the Rapyuta ASRS targets a single bin, allowing robots to deliver bins directly to the picking station without the need for unloading before picking. Moreover, the robots don’t need to just wait their turn for picking.

While ACR systems require a separate picking area outside the storage zone, the Rapyuta ASRS integrates picking stations within the system itself. Our system uses fleet-controlled robots that avoid congestion at the picking stations and immediately move on to their next task after delivering a bin. This approach not only maximizes robot utilization but also ensures more efficient use of space.

Stacker crane and shuttle-type automated storage and retrieval systems are mechanical automated storage systems. While they offer the typical advantages of an ASRS, they are fixed installations that require extensive construction for implementation. Due to its design, it offers few benefits unless used in very tall and expansive warehouses. Also, stacker cranes, as the name implies, use cranes, which may require specific safety certifications and regular inspections.

Compared to the Rapyuta ASRS, the ASRS often provides better storage efficiency due to optimized aisle space utilization. Additionally, the Rapyuta ASRS includes standard features such as concentrated work design and error prevention functions at picking stations, and a sorting feature, often resulting in a lower initial cost.

There are various types of robotic ASRS systems. One of the most common is the cubicle type, which excels in storage efficiency. However, this type does not offer the best throughput. The Rapyuta ASRS stands out for its unique combination of flexibility, scalability, and relocatability. An apples-to-apples comparison can often overlook these critical elements. Therefore, it’s essential to clearly define your requirements to focus on finding a solution that meets the requirements most rather than just comparing product features. At Rapyuta Robotics, we provide objective consultations to help you make the best choice. Contact us to get a free consultation by our expert.

Having troubles selecting automated storage or warehouse automation solutions? We can help you clarify requirements and choose the solution that best fits your warehouse.

Rapyuta ASRS has been awarded the Good Design Gold Award in 2024

The development of Rapyuta ASRS has been supported by NEDO.

Japan India USA