Supply chain managers are reviewing their best options for automation to deliver improved warehouse and distribution center productivity, speed, and lower cost. This is especially important due to the labor constraints with warehouse associ- ates combined with high customer service expectations. Automation is in reach for many managers as proven technology that is quickly deployed is now economical.

One technology that has become very popular to address these challenges is the Pick Assist Robot. The pick assist robot is quickly deployed and can be cost effective. This overview will discuss what a Pick Assist Robot is, its functions, features, advantages, safety measures, and real-world success.

Definition and Core Functionality

What is a Pick Assist Warehouse Robot?

A Pick Assist Robot, also known as a Pick Assist AMR (PA-AMR), is an autonomous mobile robot (AMR) designed to optimize and automate picking processes within warehouses. These robots collaborate seamlessly with warehouse associates to enhance overall efficiency.

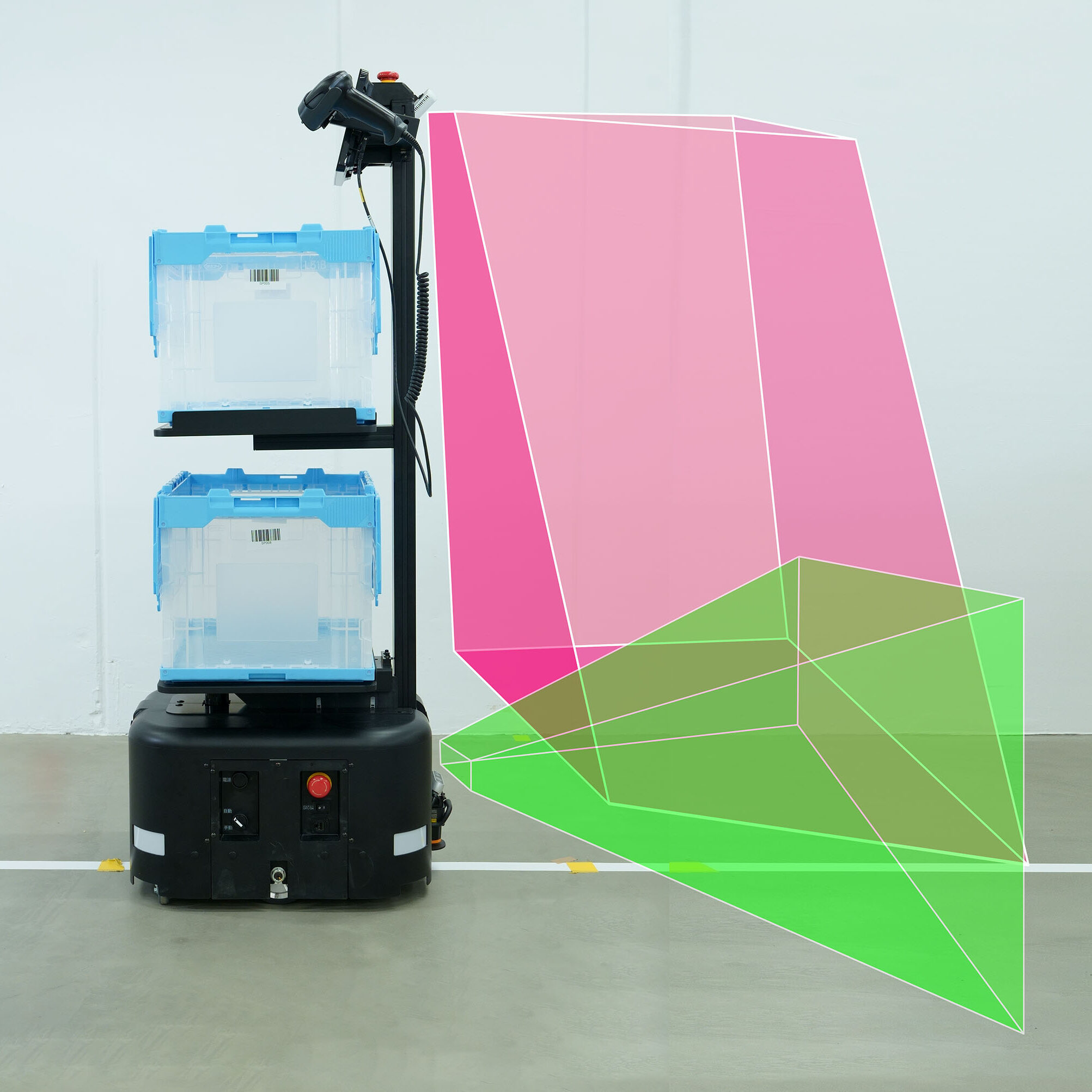

Equipped with autonomous navigation capabilities, sensors, and cameras, they navigate warehouse environments, avoiding obstacles and ensuring safe operations. With this navigation capability, Pick Assist Robots actively assist associates by carrying items from picking zones to designated areas. These AMRs handle the physical transportation of goods and allow associates to focus on more complex tasks such as picking accuracy and speed.

Through advanced features like fleet control, intelligent route planning, and real-time data visibility, Pick Assist Robots significantly improve warehouse productivity by minimizing associate travel, search times, and reducing the physical burden on warehouse associates.

Real-time visible warehouse data is available through dashboards allowing for workflow and resource optimization using Artificial Intelligence (AI). Pick Assist Robots are playing a pivotal role in improving productivity, reducing costs, and addressing the challenges associated with obtaining and retaining warehouse labor.

Role in Optimizing and Automating Picking Processes

The primary function of a PA-AMR is to streamline and accelerate the picking processes in warehouses. They work closely with associates assisting and automating some of their tasks. Associates do not need to travel the warehouse pushing carts while picking and then pushing them to destination areas.

This mobile robot solution aims to overcome the challenges related to labor scarcity, high turnover rates, and the costs associated with training new associates. This automation is crucial for meeting warehouse productivity goals while ensuring efficient customer service and cost-effectiveness.

Addresses Today’s Challenges in Traditional Manual Picking Methods

The scarcity of workers in warehouses has become a pressing issue, leading to increased operational costs. Associate retention poses another challenge, with high turnover rates requiring frequent training of new staff. Pick Assist Robots offer a more sustainable and efficient approach to warehouse operations.

Associates enjoy working with advanced technology that assists them and eliminates some of their arduous tasks such as pushing heavy carts. New employee training is much quicker as the Pick Assist Robot guides associates with optimized routes. Associates are not required to know item locations as the PA-AMR guides them to items. A manually operated warehouse can easily transform into an advanced warehouse with Pick Assist Robots.

Features

Autonomous Navigation and Operation within Warehouses

PA-AMRs use advanced autonomous navigation capabilities allowing them to operate seamlessly within warehouse environments. These robots leverage technologies such as cameras, LiDAR sensors, and navigation systems to navigate through complex spaces, avoiding obstacles, and ensuring efficient movement. AMRs run autonomously and do not need guide tape like AGVs so they can operate and respond easily to temporarily placed obstacles.

Integration with Technology

Sensors and cameras enable these robots to perceive and understand their surroundings, a crucial feature for safe and efficient operation. The integration with Warehouse Management Systems (WMS) and Enterprise Resource Planning (ERP) systems ensures real-time data use for informed decision-making.

Advanced Pick Assist Features

To further enhance efficiency, PA-AMRs may come equipped with advanced features. These include intelligent route planning, dynamic inventory tracking, and adaptive learning capabilities. These features contribute to streamlined workflows, error-free operations, and improved overall system integration.

Key Advantages

Excellent Flexibility

One of the key advantages of Pick Assist Robots is their excellent flexibility. These robots can be easily onboarded or offloaded to handle peak periods, allowing warehouses to adapt to fluctuating demand. By taking advantage of using Robots as a Service (RaaS), the fleet of Pick Assist Robots can easily be modified to economically optimize productivity.

Speed and Accuracy

Pick Assist Robots excel in enhancing speed and accuracy during picking processes. The automation of tasks allows warehouse associates to provide greater focus on picking which leads to faster order fulfillment times, meeting customer demands with greater speed and accuracy.

Collaborative Abilities

Contrary to the misconception that automation replaces human workers, Pick Assist Robots collaborate with and complement their human counterparts. This collaborative approach enhances overall productivity, as robots and humans work seamlessly together to achieve common goals. New employees can be trained easily as the pick assist robot helps guide employees enabling them to become quickly productive. Humans are great at picking tasks while robots and AI are good at analyzing vast amounts of data to design optimized picking routes and transport items.

Scalability and Flexibility with Existing Warehouses

PA-AMRs are scalable and flexible, making them suitable for various warehouse configurations. Many implementations require no significant modifications to the warehouse making implementation easy. As warehouses grow, additional robots can easily be added for additional throughput.

Safety Measures

Collision Avoidance Technologies

Safety is paramount in warehouse operations and Pick Assist Robots incorporate collision avoidance technologies to prevent accidents. These technologies use sensors to detect obstacles and adjust the AMR’s path accordingly, ensuring a safe working environment.

Emergency Stop Mechanisms

Pick Assist Robots use multiple emergency stop mechanisms for enhanced safety. These mechanisms are designed to swiftly halt robot operations in case of unforeseen circumstances, prioritizing the well-being of both the robot and nearby human workers.

Adherence to Industry Standards

Pick Assist AMRs adhere to industry-specific safety standards and regulations. This commitment ensures that the implementation of this technology aligns with established guidelines, fostering a secure working environment.

Fire-Safe System – Auto Park

In addition to collision avoidance and emergency stop mechanisms, PA-AMRs often feature fire-safe systems with auto-park capabilities. This ensures that in the event of a fire or other emergencies, the robots are safely parked, mitigating potential hazards.

Real-World Success

The implementation of Pick Assist Robots has yielded tangible benefits in real-world scenarios. Warehouses that have embraced this technology report significant improvements in order fulfillment time and overall productivity. The metric of “picks per hour” has seen remarkable enhancements, showcasing the efficiency and effectiveness of these robots in picking operations.

Today’s Warehouse

Pick Assist AMRs are no longer futuristic technology but a proven solution ready for implementation today. They are ideal for large and small warehouses and ones in between. The combination of proven performance, quick cost-effective deployment, and safety measures makes PA-AMRs a transformative force in the deployment of warehouse automation.

Advanced features such as Picker Guidance System, Put-to-Light, and AI optimized zone picking are available on the Rapyuta PA-AMR platform which is repeatedly generating a 2x productivity improvement with picking accuracy rates above 99.9%. These features combined with its easy-to-use platform ensure operations can quickly benefit from PA-AMRs.

Pick assist robots quickly enhance productivity, lower costs, and labor requirements. They stand at the forefront of the ongoing adoption of automation with supply chain management. The future of warehousing is here.

To know more about Rapyuta Pick Assist Robots, one of the world’s leading manufacturers, or to request a consultation, contact us here.

https://www.rapyuta-robotics.com/warehouse-automation-robots-demo/