A Fulfillment Revolution in Fashion is No Longer Optional

The global apparel industry is no longer operating on seasonal rhythms—it is moving at the speed of the consumer. With fashion brands releasing micro-collections every few weeks, and consumers expecting real-time product availability, next-day delivery, and flexible returns, the pressure on apparel distribution centers has reached unprecedented levels.

Apparel fulfillment is no longer about just moving boxes. It’s about managing tens of thousands of SKUs—each with slight variations in size, color, fabric, and fit. It’s about seamlessly serving both D2C and B2B channels. It’s about processing high return rates without bottlenecks. And it’s about doing all this faster, cheaper, and more accurately than ever before.

At the heart of this transformation lies a critical reality: traditional manual warehouse operations can no longer keep up.

For apparel brands and 3PLs operating fulfillment centers, it’s time to evolve beyond labor-intensive processes, linear workflows, and fragmented visibility. What’s needed is an intelligent, scalable, and automation-first approach—and Automated Storage and Retrieval Systems (ASRS) stand at the forefront of this shift.

This blog takes a deep dive into the top 12 apparel warehouse challenges stifling growth and efficiency—and then shows how Rapyuta ASRS addresses them through robotic precision, modular design, and operational intelligence.

The 12 Most Critical Challenges in Apparel Warehouse Today

1. SKU Explosion and Inventory Chaos

Apparel thrives on rapid design cycles and constant style refreshes. Every new collection introduces thousands of new SKUs, each with slight differences—XS to XXL, red to burgundy, short sleeves to 3/4 sleeves.

In most warehouses, this leads to:

- Overcrowded shelving

- Misplaced or wrongly slotted items

- Time-consuming put away processes

- Complicated replenishment and order batching

Even WMS systems struggle to keep up when the physical environment lacks the structure to mirror digital accuracy. As SKU count grows, so do errors and delays—directly affecting customer satisfaction and returns.

Tired of Misplaced SKUs and Inventory Inaccuracy?

Start automating with Rapyuta ASRS and take control of your SKU-heavy apparel inventory with bin-level traceability and real-time WMS sync

2. Excessive Travel Time in Manual Picking

A warehouse associate may walk 5–10 miles per shift in a traditional fulfillment center. In apparel warehouses, where product density is high and order profiles are complex, this walking time becomes the single largest inefficiency in the operation.

For example:

- Picking a multi-line order may require 10+ minutes of walking

- Replenishment tasks require back-and-forth trips across zones

- Order consolidation is delayed due to physical separation

This not only limits pick rates but leads to fatigue, inconsistency, and rising labor costs.

3. Underutilization of Vertical Storage Space

Warehouses may have 20-foot ceilings, but many apparel facilities use only the lower 6–8 feet. Why?

- Manual picking makes it unsafe or impractical to use high racks

- Ladders and mezzanines slow down operations

- Traditional racking lacks the flexibility to reconfigure based on SKU velocity

As inventory expands, operators often respond by expanding square footage—rather than optimizing existing volume.

4. Inability to Efficiently Process Returns

Returns on apparel can be as high as 30–40%, especially for online orders. However, most warehouses treat returns as an afterthought—processed manually, inspected slowly, and stored in bulk bins without reintegration into active inventory.

This leads to:

- Delayed resale of returned items

- Higher out-of-stock rates (even if the item is physically in the building)

- Fragmented inventory accuracy

The result? Lost revenue and increased carrying costs.

5. Order Complexity in Fashion Retail

Apparel orders often include multiple SKUs from various categories:

- Tops + bottoms + accessories

- Different sizes and colors in the same order

- Mixed B2B and D2C fulfillment profiles

Traditional zone-picking makes it difficult to synchronize these picks efficiently. Orders get delayed at the packing station or require manual consolidation, both of which reduce throughput and increase error rates.

6. Peak Volume Volatility

Apparel warehouses operate in highly volatile demand environments:

- Flash sales

- Influencer-driven spikes

- Seasonal booms (e.g., back-to-school, holidays)

Without scalable automation, these spikes overload manual systems. The effects include SLA failures, shipping delays, overtime labor costs, and reduced customer satisfaction.

7. High Error Rate in Manual Picking

Apparel SKUs are often visually similar. A navy large T-shirt looks almost identical to a black XL T-shirt—until it reaches the wrong customer.

In manual systems:

- Pickers rely on visual matching or barcodes

- Fatigue leads to oversight

- No automated check confirms correct picks before packing

Each error damages the customer relationship and contributes to increased returns and support costs.

High Picking Errors Costing You Customers?

Eliminate size, color, and style mismatches with projector-guided picking, sensor validation, and real-time monitoring—engineered for SKU-dense apparel environments.

8. Slow Receiving and Put away

Inbound shipments must be inspected, counted, and stored quickly to ensure availability. But apparel items—especially when coming from overseas in bulk cartons—require individual SKU verification.

In manual environments:

- Items wait at the dock for space or labor availability

- Put away decisions are made reactively

- Visibility into what’s available is delayed by hours or days

This delay ripples across all downstream operations.

9. Static Slotting and Lack of Velocity-Based Organization

SKU popularity changes rapidly in fashion. Today’s bestseller is tomorrow’s clearance item. Yet most warehouses don’t adapt their slotting accordingly.

This leads to:

- Slow movers occupying prime slots

- Hot items placed in hard-to-reach areas

- Increased pick times for trending products

Manual re-slotting is time-consuming and disruptive, so it’s rarely done as frequently as it should be.

10. Labor Shortages and Training Bottlenecks

With labor availability shrinking and turnover rising, apparel warehouses are constantly onboarding new associates.

But:

- SKU familiarity takes time

- Warehouse layout navigation is complex

- Seasonal labor makes errors more likely

Training becomes a recurring drag on productivity, and every ramp-up period comes with risk.

11. Omnichannel Fulfillment Conflict

One warehouse now serves many masters:

- Retail replenishment with strict cutoffs

- D2C orders with next day promises

- Marketplace fulfillment with packaging/label requirements

When systems aren’t equipped to prioritize and differentiate these flows automatically, chaos ensues—and someone’s SLA gets missed.

12. Invisibility in Inventory and Workflow

Without real-time system integration, managers can’t answer simple questions like:

- “How many size M black joggers are really available?”

- “Which orders are stuck and why?”

- “Which operator is underperforming?”

This lack of visibility leads to reactive firefighting instead of proactive decision-making.

7 Advanced Ways Rapyuta ASRS Optimizes Apparel Fulfillment Operations

1. Structured SKU Storage with Intelligent Bin Management

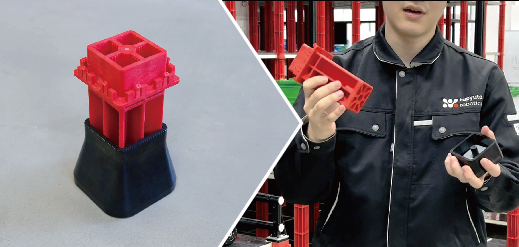

One of the most common operational bottlenecks in apparel warehouses is the physical organization of SKUs. Apparel items—especially those that appear visually similar—require an extremely structured storage method that supports both high SKU count and rapid changes in product mix. Rapyuta ASRS addresses this complexity by introducing standardized BIN-based storage with intelligent slotting capabilities.

Each storage BIN in the ASRS is designed to be subdivided into configurable slots, which means multiple product variants (e.g., different sizes or colors of the same SKU) can be stored in a single container—while still being traceable individually. These bins are then managed by an integrated ASRS software platform that knows exactly where every item resides. Slot patterns can be customized (from no division up to 6×6 slots per BIN) depending on the SKU dimensions and pick frequency.

Key technical features:

- Configurable BIN structures (e.g., 124L or 75L with modular stacking walls)

- Support for multiple SKU slot configurations with system registration

- Real-time system mapping of BIN ID, slot configuration, and inventory count

- Automated optimization of BIN usage to avoid dead space or obsolete storage

This system removes the reliance on human memory or fixed shelving and ensures that the WMS always reflects actual, up-to-date stock levels.

2. Robot-Powered Bin-to-Person Picking

In contrast to traditional picking models where workers travel to the product, Rapyuta ASRS flips the paradigm: products come to the picker via autonomous robots. This is enabled through a highly coordinated robot fleet that moves across a modular grid, retrieving assigned SKU bins and delivering them to designated workstations.

The picking station itself is ergonomically designed in a C-shaped layout, where multiple bins are staged simultaneously. Operators interact with the system using intuitive visual cues projected directly onto the bin. Instructions such as which product to pick, where to place it (into the corresponding order bin), and the exact quantity are all displayed on an overhead monitor.

What happens under the hood:

- ASRS robots receive pick instructions via centralized control server

- Robots lift and transport the bins, traveling up to 6.27 mph with <1″ vertical clearance

- Robots queue up to eight SKU bins at the picking station to maximize efficiency

- Sensors and projectors guide the picker, and confirmation buttons ensure validated picks

- The system immediately schedules the next set of bins for retrieval, eliminating wait times

Because the bins are robot-delivered, travel time is eliminated entirely. The system is also intelligent enough to group bins based on current order batching to minimize repeat retrieval.

3. High-Density, Multi-Level Vertical Storage System

Rapyuta ASRS utilizes a modular framework that can be built vertically to maximize space utilization—an essential feature for apparel warehouses that are often constrained by floor area. The system supports configurations of up to nine tiers, totaling nearly 17 feet in vertical storage height.

Unlike conventional static racks or mezzanines, this structure is specifically designed to support robot movement and structural integrity:

- The ASRS racks are composed of modular “plate and pole” combinations that allow flexible vertical assembly.

- Specialized robot elevators are installed to facilitate smooth vertical transport of bins.

- The system can handle weight loads of up to ~1,990 lbs. per square meter (in high-capacity setups), making it suitable even for dense or boxed apparel storage.

Each bin’s location is accessible without human effort, which means even the topmost tier is as reachable as the bottom—entirely via robotic automation. This allows the warehouse to triple its vertical usage without compromising safety, speed, or accessibility.

Modular Warehouse Automation

Deploy modular warehouse automation that scales throughput without expanding headcount — perfect for seasonal volume surges and flash-sale spikes.

4. Dynamic Returns Processing and Reintegration

The returns process in apparel fulfillment is notorious for its complexity, largely because it is manual, slow, and detached from inventory systems. Rapyuta ASRS solves this by enabling returns to be treated like new inbound stock, with automated reintegration into the inventory flow.

The system includes dedicated drop-off and stowing stations designed for reverse logistics:

- Returned items are received and inspected by operators.

- The ASRS software dynamically assigns an optimal storage location based on item dimensions, historical velocity, and bin availability.

- The item is placed into a bin, registered via handheld terminal or station interface, and robotically transported to the assigned location.

- Inventory levels are updated in real time via API integration with WMS or ERP systems.

This closed-loop process ensures that returned SKUs are immediately visible in the system and eligible for order fulfillment—minimizing lost opportunity due to processing delays or “invisible inventory.”

5. Parallel Order Fulfillment and Batch Processing

Apparel orders are rarely single-line—they involve multiple SKUs per customer, often spread across categories like tops, pants, undergarments, and accessories. Rapyuta ASRS supports this through its parallel order processing capabilities, which allow a picker to handle multiple orders simultaneously at a single station.

The system:

- Determines the optimal grouping of picks based on current order volume and SKU overlap

- Sequences bin delivery to minimize operator idle time and maximize SKU-to-order bin efficiency

- Displays visual sorting cues on screen and via projection to guide the picker to the correct order bin

Each picking station supports simultaneous processing of multiple customer orders, with designated order bins per task. This eliminates the need for downstream order consolidation or sorting zones.

6. Elastic and Modular Scalability

One of the critical differentiators of Rapyuta ASRS is its modular scalability, allowing warehouse operators to add capacity without major construction or downtime.

The entire ASRS structure—racks, robots, picking stations, and servers—is designed with plug-and-play architecture:

- Do you need more storage? Add more vertical poles and plates.

- Do you need higher throughput? Add more robots and picking stations.

- Do you need different bin types? The system supports both plastic and cardboard bins, and multiple slot formats.

The internal robot network is orchestrated by edge servers that balance task assignments and avoid congestion. Battery changers and charging stations are placed strategically, allowing robots to operate continuously through peak cycles.

This flexibility enables the warehouse to scale not just for growth—but also to respond to seasonal or campaign-based spikes without hiring additional staff or investing in short-term infrastructure.

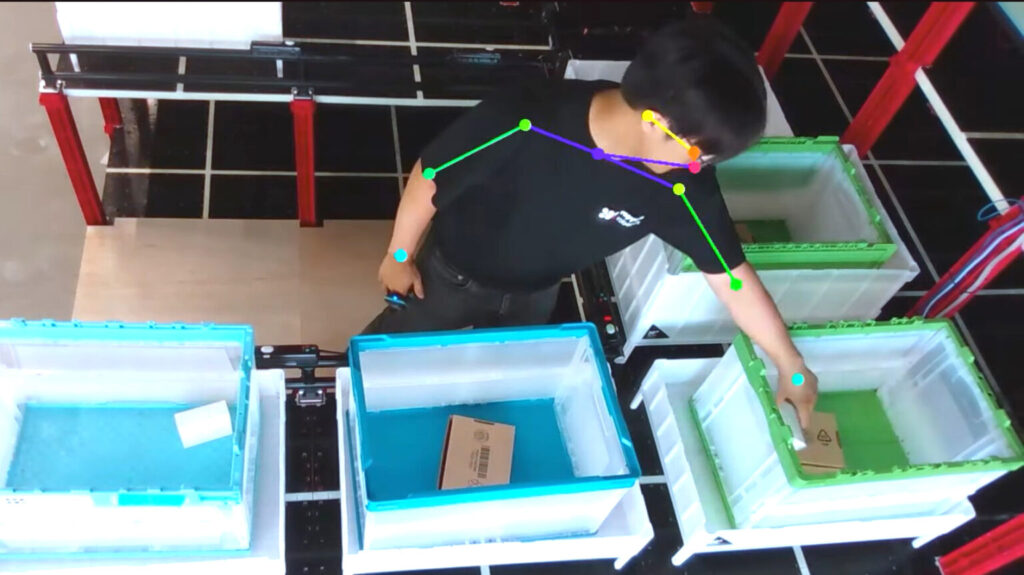

7. Visual, Sensor-Based Accuracy Controls

Manual operations in apparel warehouses suffer from high error rates, especially when SKU variants are visually similar. Rapyuta ASRS solves this through a multi-layered accuracy system that guides, validates, and audits every pick action.

The accuracy system includes:

- Overhead projectors that spotlight the correct SKU within the bin

- Monitors that show the item image, product name, barcode, and pick quantity

- Motion sensors and physical buttons that confirm each action is completed

- Handheld terminals that allow manual override or exception handling

Each time a pick is completed, the system checks that the correct item has been selected and moved to the correct order bin. If discrepancies are detected—either by lack of button press, motion irregularity, or barcode mismatch—the system halts the process and requests operator review.

Additionally, the system tracks:

- Picks per hour

- Error rates per operator

- Real-time order bin status

- Inventory movements down to the slot level

This level of granularity creates a feedback loop of continuous improvement while protecting against quality breakdowns that impact customer satisfaction.

Conclusion: Transforming Apparel Fulfillment from Bottleneck to Competitive Edge

The apparel industry has always moved fast—but today, the pace has accelerated to a point where only the most agile and intelligent fulfillment operations will survive. The rise of apparel D2C channels, and hyper-personalized consumer expectations has redefined what it means to run a warehouse.

The old model—built around static shelving, manual picking, and labor-heavy workflows—is no longer sufficient. It breaks under the weight of SKU complexity. It fails during demand spikes. It cannot deliver the accuracy, speed, and flexibility modern brands require.

By adopting Rapyuta ASRS, apparel brands and 3PLs unlock the ability to:

- Scale performance exponentially — Achieve up to 10x faster picking speeds and 2.5x higher storage density with bin-to-person robotics and multi-level modular racking, without increasing warehouse footprint.

- Ensure accuracy and operational consistency — Eliminate walking, reduce pick errors with projector-guided validation, streamline returns, and minimize training time through intuitive, sensor-backed workstations.

- Gain real-time visibility and flexibility — Seamlessly integrate with WMS, dynamically re-slot inventory based on demand shifts, and scale robot fleets or racks on demand—without disrupting live operations.

If your warehouse is feeling the strain of fashion’s new velocity, if your team is constantly fighting to meet SLAs, if your floors are crowded while your vertical space sits idle—it’s time to take the next step.

Book a consultation to explore how Rapyuta ASRS can be customized to your apparel fulfillment needs. Whether you’re retrofitting an existing warehouse, launching a new site, or starting with a scalable pilot, our automation experts will help you design a roadmap that maximizes space, speed, and ROI.

FAQs

1. What are the biggest warehouse challenges in apparel fulfillment?

Apparel fulfillment faces challenges like SKU proliferation, high return rates, manual picking inefficiencies, and poor vertical space utilization. These issues affect picking speed, order accuracy, and overall fashion logistics performance.

2. How does ASRS help apparel warehouses manage high SKU volumes?

An Automated Storage and Retrieval System (ASRS) uses intelligent bin-based storage and robotics to organize and retrieve apparel SKUs efficiently. It eliminates SKU misplacement, improves picking speed, and optimizes space in high-density fashion warehouses.

3. Why is warehouse automation important for fashion and retail distribution?

In apparel and retail distribution, consumer demand shifts quickly. Warehouse automation helps apparel 3PLs and retailers scale up operations, reduce errors, and meet delivery SLAs without relying solely on labor-intensive processes.

4. Can ASRS be used in existing apparel distribution centers?

Yes. ASRS systems like Rapyuta are modular and can be retrofitted into existing apparel warehouses. This makes it possible to automate without major facility overhauls—ideal for apparel brands and 3PLs optimizing current infrastructure.

5. How does ASRS improve apparel returns processing and reverse logistics?

ASRS enables faster reintegration of returned fashion items into active inventory by automating drop-off, stowing, and bin allocation. This reduces processing delays and improves inventory availability across the supply chain.

6. What KPIs improve with ASRS in apparel fulfillment operations?

Key performance indicators (KPIs) that improve include picking rate (up to 10x), space utilization (up to 2.5x), order accuracy, training time, and return processing speed—critical for fashion retailers and fulfillment providers.

7. Is ASRS suitable for fast-changing fashion logistics and SKU turnover?

Absolutely. ASRS is ideal for high-SKU turnover and trend-driven assortments. It supports dynamic re-slotting, API-based WMS integration, and flexible workflows, making it a strong fit for agile fashion logistics and modern apparel supply chains.