The rise of e-commerce, unpredictable market demands, and labor shortages have left warehouses, particularly 3PLs, grappling with unprecedented challenges. Manual processes often lead to inefficiencies, slower fulfillment rates, and operational bottlenecks. This is where Automated Storage and Retrieval Systems (ASRS) step in to revolutionize warehouse operations.

For 3PLs, the stakes are high: with global e-commerce sales projected to surpass $7.5 trillion by 2030, the demand for faster, error-free order fulfillment has never been greater. Warehouses must manage SKU diversity, handle seasonal spikes, and ensure accuracy—all while controlling costs. Implementing an ASRS isn’t just a convenience; it’s a necessity to remain competitive in this high-pressure environment.

Rapyuta ASRS is designed to address these challenges head-on. With advanced features like modular design, high-speed omnidirectional robots, and intelligent multi-robot collaboration, it simplifies operations while boosting productivity and scalability. Let’s explore six unique features that set Rapyuta ASRS apart.

1. Modular Design for Maximum Flexibility

The Rapyuta ASRS is built with a modular design, offering unmatched adaptability to warehouse layouts of all shapes and sizes. Its components—Base Blocks, Poles, and Floor Panels—make it easy to customize and scale.

- Anchorless Structure: Eliminates the need for anchors while offering seismic resistance and effortless relocation.

- Custom Configuration: Picking Stations, Lifts, and Charging Stations are tailored to meet specific operational requirements.

- Seamless Scalability: Allows reconfiguration and expansion with minimal impact on operations.

This modular design ensures flexibility, making it ideal for dynamic warehouse environments.

2. Lightning-Fast and Omnidirectional Robots

Rapyuta ASRS robots are engineered for speed, precision, and adaptability, setting new standards in warehouse automation.

- Access Anywhere: Robots can reach bins in any location, whether horizontally or vertically, ensuring direct and efficient delivery.

- Lightning Speed: Operating at speeds of up to 2.5 meters/second (8.2 feet/second), robots quickly complete tasks on optimized routes.

- 360° Movement: Mecanum wheels enable omnidirectional motion without pauses, maximizing speed and efficiency.

- Across the Floors: High-speed lifts facilitate movement between floors, while bins are dynamically positioned based on SKU shipping frequency for faster access.

These robots enhance operational efficiency, ensuring swift and precise picking and delivery.

Looking to improve your warehouse efficiency? Let’s discuss how ASRS can help.

3. Proven Multi-Robot Collaboration

Rapyuta Robotics’ advanced AI ensures seamless coordination of a large fleet of robots, delivering exceptional performance in complex warehouse operations.

- >300 Robots Working Together: The system can manage over 300 robots, coordinating tasks across levels and positions.

- Optimized Collaboration: Robots dynamically adjust workflows to ensure smooth operations and high productivity.

- Seamless Multi-Level Integration: Robots and lifts work together across multiple floors, enabling efficient bin retrieval and delivery.

This robust multi-robot collaboration ensures scalability and efficiency in high-demand warehouses.

4. Efficient Picking Stations

The ASRS is equipped with advanced picking stations that enhance accuracy, reduce inefficiencies, and streamline workflows.

- Simultaneous Order Processing: Handles multiple storage and shipping bins at the same time, increasing throughput.

- Continuous Operation: Robots ensure uninterrupted workflows by delivering bins promptly, eliminating downtime.

- Integrated Workflow: Combines storage, sorting, and picking seamlessly within one system.

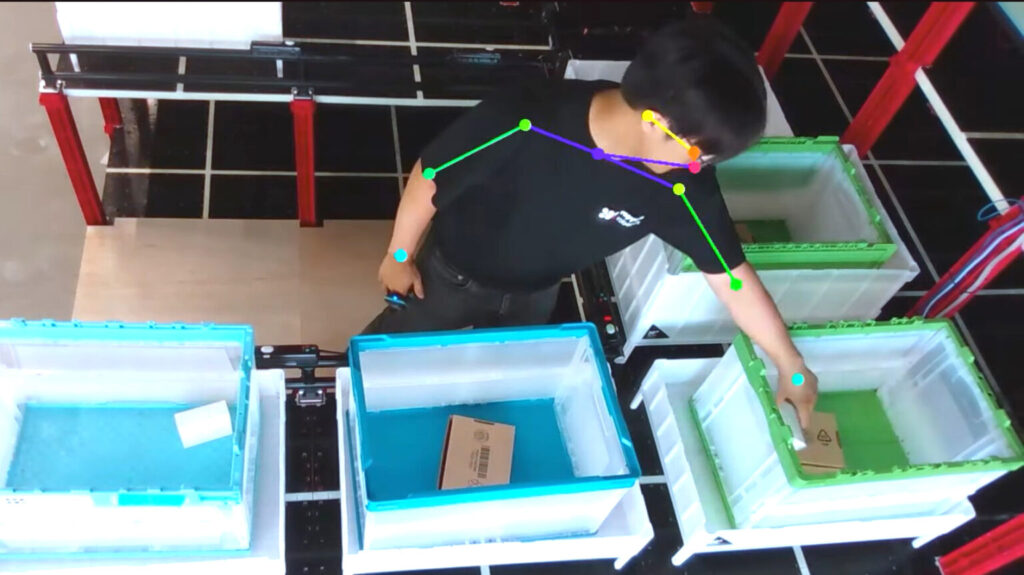

Error Elimination: Triple Error Prevention System

Rapyuta ASRS integrates a Triple Error Prevention System at its picking stations, ensuring precision in every task:

- Display Navigation: Visual guides at the picking station show the items to be picked, the quantity, and the source and destination bins. This intuitive interface allows anyone, regardless of language, to perform picking tasks accurately.

- Motion Capture: Dual motion capture cameras monitor workers’ movements. If the worker attempts to pick from the wrong bin or scan an incorrect item, an alert sound and red light provide immediate feedback, ensuring accuracy.

- Finish Button: The worker completes each task by pressing the Finish Button. If an error is detected by the motion capture system, the button becomes unresponsive until the error is corrected.

This triple-layered system eliminates errors, making the picking process simple, intuitive, and highly reliable.

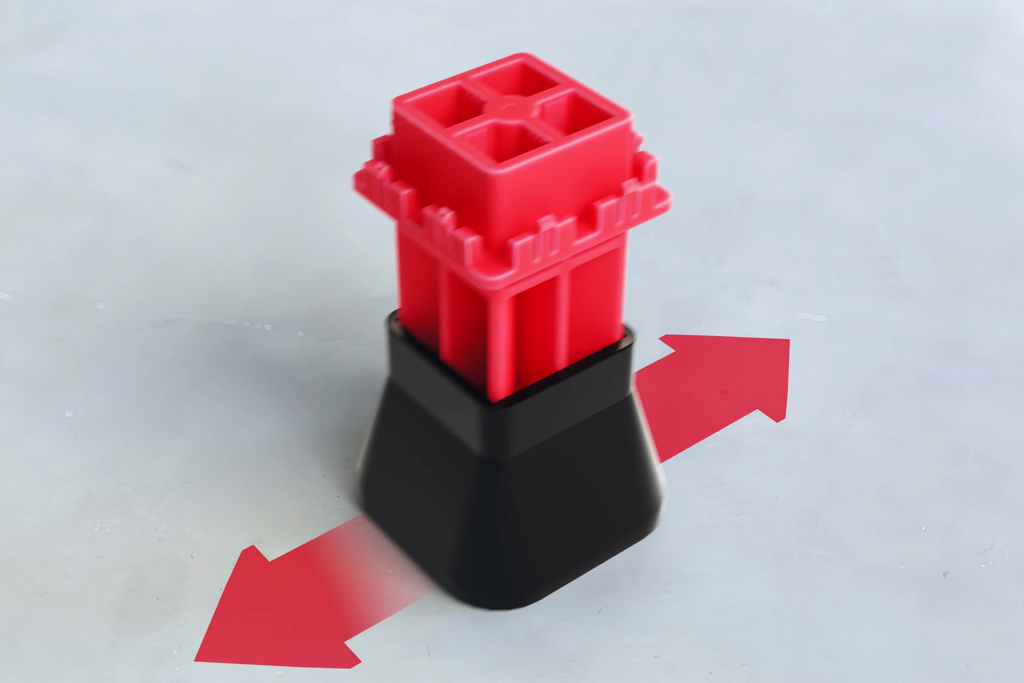

5. Earthquake-Resistant Construction

Warehouse safety is paramount, and Rapyuta ASRS delivers with its earthquake-resistant features.

- Seismic Isolation: Anchorless base blocks and isolators absorb vibrations, ensuring stability during seismic events.

- Proven Durability: Tested using 3D vibration tables to withstand extreme conditions.

This construction provides safety and reliability, ensuring uninterrupted operations even in high-risk areas.

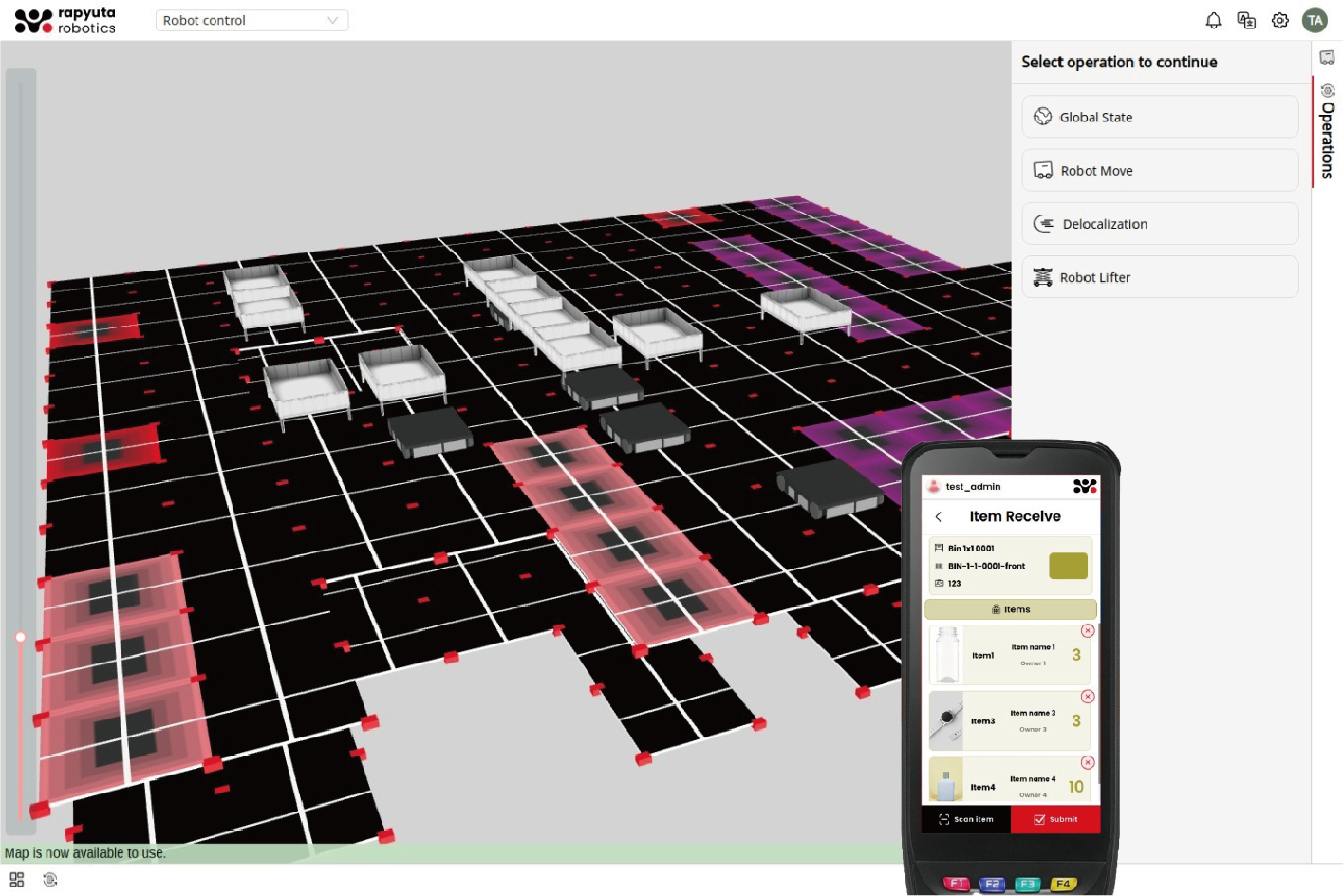

6. Rapyuta ASRS and WMS Integration

Rapyuta ASRS seamlessly integrates with Warehouse Management Systems (WMS), enabling real-time visibility and control over warehouse operations. This integration allows automated synchronization of inbound, outbound, and inventory management processes, reducing manual intervention and errors.

- Optimized Inventory and Order Fulfillment

- With real-time inventory tracking, the integrated WMS ensures precise stock management by mapping items using bin IDs and QR codes. This minimizes misplaced items and enhances order accuracy.

- Additionally, the WMS intelligently batches orders, prioritizing SKU movements and optimizing picking sequences. This automation significantly reduces fulfillment delays while improving warehouse efficiency.

- Advanced Robot Coordination and System Control

- Rapyuta ASRS-WMS integration provides a real-time digital map to monitor robots, bins, and floor panels, ensuring optimized picking routes and efficient movement. It also enables seamless collaboration with external automation like Pick Assist AMRs, allowing warehouses to handle oversized or infrequent items efficiently.

- Moreover, centralized command features let managers oversee Rapyuta ASRS functions, control lifters, and direct robot operations from a single interface, ensuring smooth and coordinated warehouse automation.

Conclusion

Rapyuta ASRS delivers measurable results, helping warehouses achieve 10x productivity improvements and 2.5x better storage efficiency. By simplifying workflows, reducing errors, and maximizing available space, it provides a practical path to handle increasing demands without overextending resources.

For warehouses managing high SKU counts, unpredictable order volumes, and labor challenges, Rapyuta ASRS offers a clear way to meet operational goals. It’s built to adapt to your needs, scale with your business, and deliver consistent results.

Contact us today to explore how Rapyuta ASRS can transform your warehouse into a high-performance hub of efficiency and accuracy.