Retail distribution centers are facing pressure like never before. The rise of eCommerce has transformed fulfillment expectations from “fast and accurate” to “instant and flawless” — not just during peak season, but all year long. When seasonal surges hit — from Black Friday and Singles’ Day to back-to-school and holiday rushes — even the most sophisticated retail warehouse operations are pushed to their limits.

Order volumes can spike by 5x in a matter of weeks, while customer patience for delays or errors drops to zero. SKU counts increase, labor availability tightens, and floor space runs out. Yet most retail fulfillment operations still rely on outdated infrastructure: fixed racking, manual picking, spreadsheet-driven inventory control, and labor-heavy workflows. These methods are no longer sufficient — and during peak times, they often collapse.

Industry research supports this: over 70% of retail warehouse operators report missing fulfillment KPIs during seasonal spikes, citing bottlenecks, errors, and staffing issues. The result? Lost revenue, damaged brand trust, and soaring operational costs at the most critical time of the year.

In this high-pressure landscape, automation isn’t just a long-term investment — it’s a short-term necessity. But not all automation addresses the root causes of peak failure. Retailers need a system purpose built for scalable throughput, dynamic inventory control, and space-efficient design.

This is exactly what Rapyuta Automated Storage and Retrieval System (AS/RS) delivers. Designed for modern retail distribution environments, Rapyuta ASRS combines intelligent robotic coordination, high-density modular storage, and real-time system integration — empowering retail fulfillment teams to scale without compromise, adapt without disruption, and deliver without delay.

In the sections ahead, we explore the most pressing seasonal challenges for retail warehouses — and how Rapyuta ASRS offers a powerful, future-ready solution for each one.

1. The Reality of Seasonal Surges in Retail Distribution

Peak season introduces 3x–5x volume spikes compressed into just a few weeks. Fulfillment teams are expected to do more with less time, often with the same workforce and infrastructure.

Traditional warehouses aren’t designed to absorb that shock. Orders pile up, inventory bottlenecks, and accuracy drops just as customer expectations rise. Temporary labor can’t close the gap. Managers spend more time on firefighting than optimizing. The result? Customer satisfaction erodes at the exact moment you need to perform at your best.

Solution:

Rapyuta ASRS turns volatility into throughput. By deploying autonomous robots and modular racking, the system:

- Delivers up to 400 bins/hour per picking station to meet compressed fulfillment timelines

- Dynamically prioritizes bin delivery based on SKU velocity and order urgency

- Integrates with ERP/WMS systems via RESTful APIs for seamless order handling

- Absorbs sudden order spikes without adding labor or disrupting layout

This allows operations to ramp up output during peak season without breaking the system—or the team.

2. Why Static Storage Systems Collapse During Peaks

Fixed shelving and slotting layouts lack flexibility. When SKU demands shifts, re-slotting becomes a manual, time-consuming task that facilities can’t afford during peak hours.

Without dynamic inventory placement, teams lose valuable hours—and productivity. Pickers face long walking paths, congested aisles, and misaligned SKU positions that increase cycle times and fatigue.

Solution:

Rapyuta ASRS replaces rigidity with intelligent, dynamic coordination:

- Virtual slotting: SKU locations are software-managed and changeable on demand

- No physical re-slotting required — the system reprioritizes bin delivery in real time

- Slot-based bin configurations allow mixed SKU storage and higher density

- Robots move freely without aisle dependency, avoiding congestion

The result is a fluid system that adapts instantly to shifting priorities—keeping pace with real-time order flow.

3. ASRS as a Strategic Answer to Volume Volatility

Sudden order surges driven by flash sales or marketing campaigns overwhelm manual picking systems. Traditional WMS routing cannot dynamically reprioritize fulfillment tasks at a speed.

Operations become reactive. Supervisors manually shift picking priorities. Staff scramble. Urgent orders get stuck behind slower-moving ones. The operation loses control at the exact moment precision is most needed.

Solution:

Rapyuta ASRS enables real-time, intelligent workload distribution:

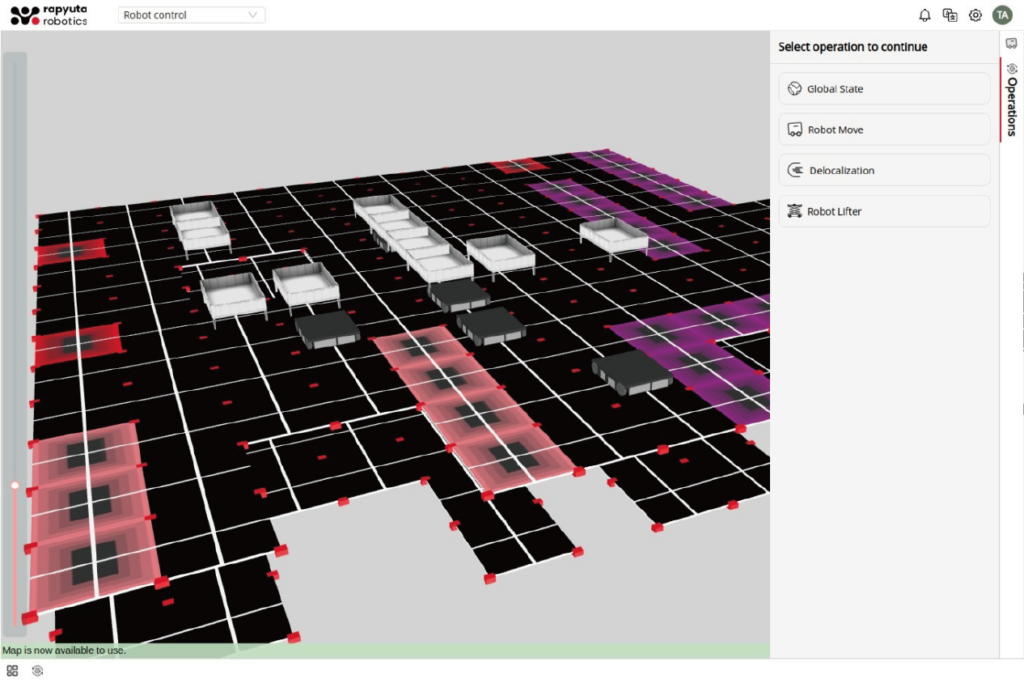

- Robots receive commands dynamically from a central control system based on live order data

- Autonomous elevator use and multi-level access ensure no bin is too far away

- Multi-robot coordination allows the system to balance load across the entire grid

- Continuous replenishment of high-priority bins eliminates wait time at pick stations

This means you stay in control, even when the order mixes, and SKU priorities change every hour.

4. High-Density Storage Without Facility Expansion

Growing SKU counts and seasonal overstock strain warehouse footprints. Expansion is often off the table due to cost, time, or zoning restrictions.

To compensate, teams fill aisles with pallets, limit mobility, and create dangerous work conditions. Overflow space reduces visibility, increases cycle time, and adds rental costs.

Solution:

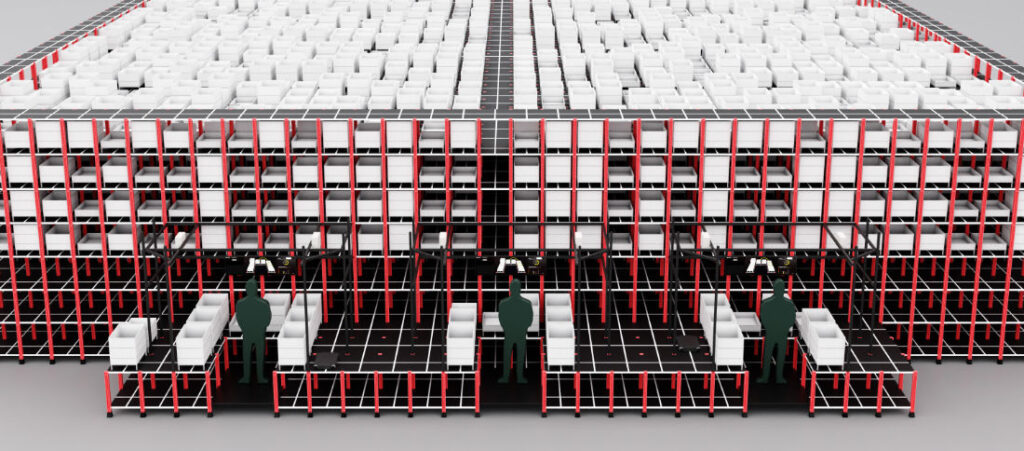

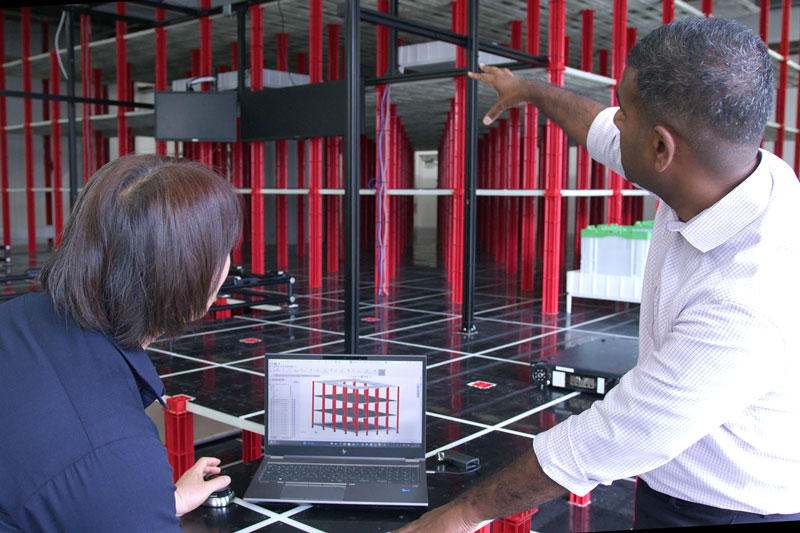

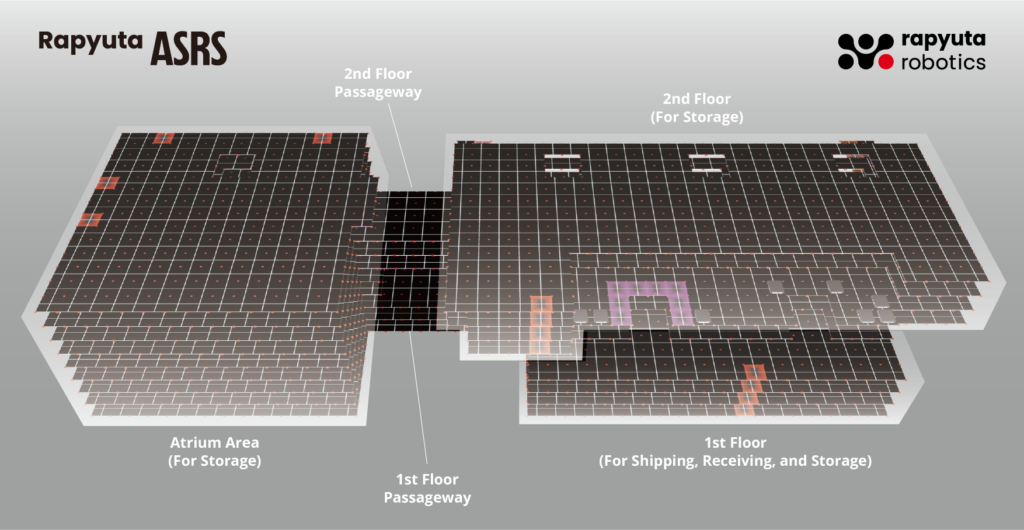

Rapyuta ASRS reclaims cubic space with scalable, high-density storage:

- 9-level racking enables vertical expansion up to 16.25 feet

- Modular design fits into corners or low-ceiling zones with shortened poles

- Multiple bin sizes and slot partitions allow SKU consolidation without clutter

- Add-on modules grow capacity incrementally—no need for a full facility redesign

Instead of leasing new space, retailers expand upward, not outward—saving time, money, and complexity.

5. Productivity Transformation Through Goods-to-Person (GTP)

Manual picking operations rely heavily on walking, searching, and verifying—low-value tasks that eat into productivity and increase error rates.

During peak, even experienced pickers struggle. Temporary workers can’t be trained fast enough. Efficiency dips just as demand peaks, creating longer lead times and dissatisfied customers.

Solution:

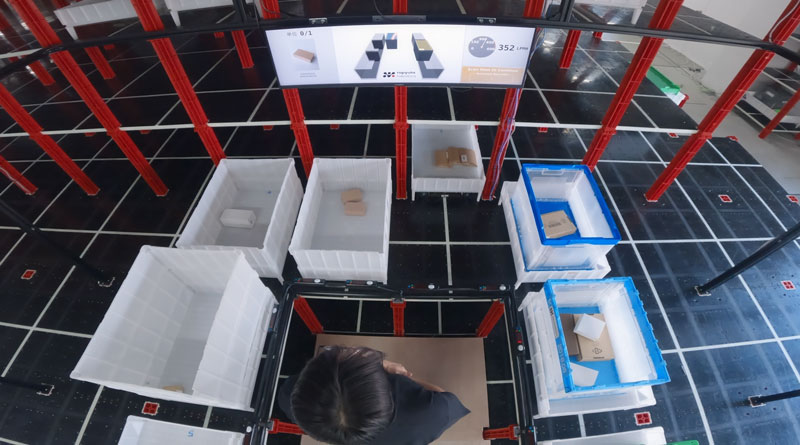

Rapyuta’s GTP model automates the picking workflow end-to-end:

- Robots deliver multiple bins to ergonomic C-shaped picking stations

- Projectors illuminate pick slots, and sensors confirm hand movement

- High-resolution screens guide the operator with SKU image, quantity, and order bin

- No walking or searching — the next task appears instantly

The picker simply picks. Accuracy improves, fatigue drops, and throughput rises—no retraining or process overhaul required.

6. Navigating Labor Volatility with Lean Automation

Seasonal labor is increasingly scarce, unreliable, and expensive. Hiring spikes during peak seasons place immense pressure on HR and operations.

Turnover is high. Training is slow. Even if you find workers, many don’t reach productivity benchmarks until the season is over. Overtime costs rise. Morale drops. SLAs are missed.

Solution:

Rapyuta ASRS de-risks peak season by making output less dependent on labor:

- Robots handle 100% of internal transport — no forklifts, no runners

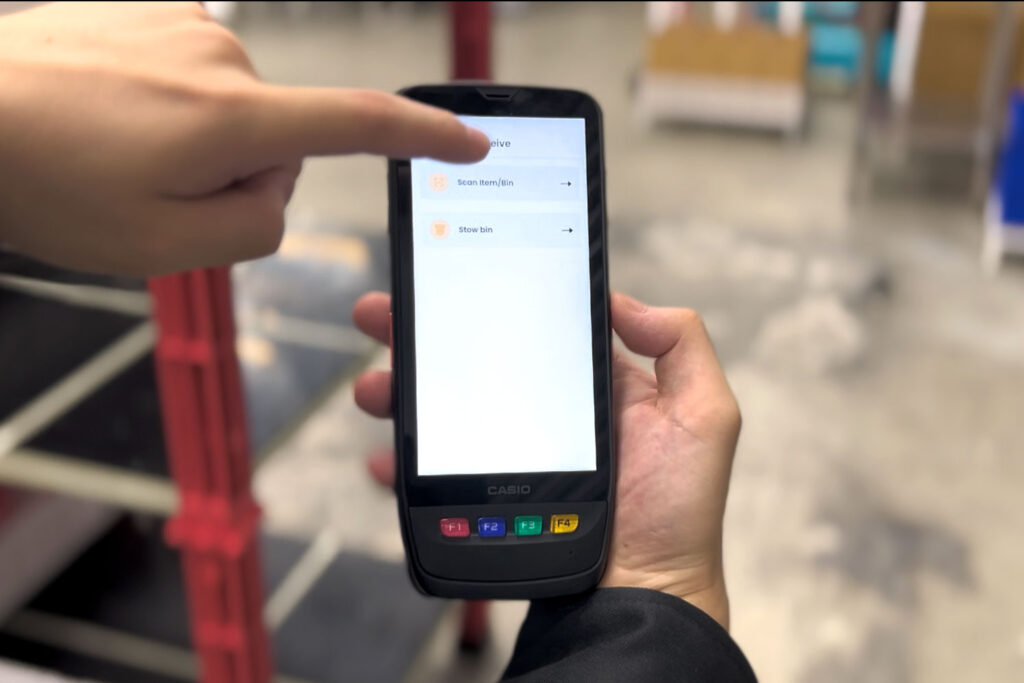

- Handheld terminals and intuitive UIs reduce onboarding to hours

- Lean teams can achieve full output with minimal fluctuation in staffing

- System uptime and maintenance are managed remotely with 24/7 support

This ensures operational continuity even when labor conditions are unpredictable.

Labor shortages disrupting your retail fulfillment operations?

Find out how Rapyuta ASRS enables stable performance with minimal seasonal hiring or overtime

7. Lead Time, Phased Implementation & Deployment Simplicity

Many warehouse leaders delay automation due to perceived complexity and risk—especially close to peak. They fear downtime, layout changes, or system conflicts that could worsen performance. As a result, they rely on outdated processes even when automation could save the season.

Solution:

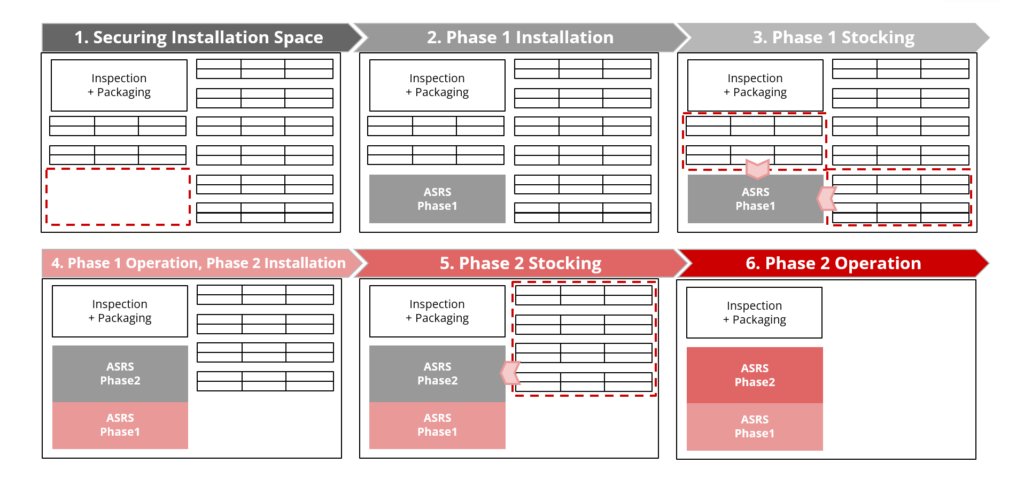

Rapyuta ASRS is designed for low risk, phased rollouts:

- Deploy in stages — start with a few stations and scale as needed

- Compact layout footprint (8×3 plates) enables easy retrofitting

- Plug-and-play API integration reduces IT friction

- Remote commissioning and training accelerate time to value

This allows teams to start small, prove ROI quickly, and grow confidently—without betting on the whole operation on Day 1.

8. Data-Driven Inventory Accuracy and Control

Inventory errors during peak lead to backorders, overselling, and expensive customer service escalations. Teams waste time looking for misplaced SKUs. Returns pile up. Trust erodes internally and externally. The lack of real-time visibility forces conservative overstocking that ties up working capital.

Solution:

Rapyuta ASRS brings visibility and control to every bin:

- Real-time tracking of bin location and contents from receiving to shipping

- Dashboards show inventory status and order flow at a glance

- Spot audits and full cycle counts can be initiated without stopping operations

- ERP/WMS sync ensures accurate system-of-record data for replenishment and planning

With data flowing from hardware to dashboard, decision-makers gain the confidence to reduce safety stock and prevent costly errors.

9. Operational Resilience and Redundancy for Peak Season

Peak season magnifies the impact of any disruption—mechanical, digital, or human. A single failure can cascade into thousands of delayed orders. Manual workarounds are slow. Teams lose valuable hours. Customers vent on social media. Downtime damages trust and throw off the rhythm of your entire network.

Solution:

Rapyuta ASRS is built for resilience:

- Distributed robot architecture — if one fails, others take over the workload

- Predictive maintenance based on AI-monitored wear and usage

- Redundant elevators and power supplies ensure continuity

- Nationwide 24/7 support network with remote monitoring

This built-in redundancy means fulfillment continues, even if part of the system encounters an issue.

10. Seasonal ROI and Flexible Financing Models

Traditional automation requires high upfront investment and long ROI cycles—challenging to justify in short-term peak contexts. Budgets don’t align with urgency. Leadership is hesitant. Meanwhile, temporary fixes like overflow storage and contractor labor add recurring costs without solving root issues.

Solution:

Rapyuta ASRS offers investment models aligned with operational reality:

- Pay-as-you-scale deployment means no overbuying

- Quantifiable ROI drivers include labor reduction, fewer returns, faster cycles

- Peak-specific ROI is visible in seasonal labor savings and reduced downtime

Whether you’re looking to optimize this season or transform for next year, ASRS makes the business case clear and achievable.

Conclusion: The Future of Retail Logistics Demands Smarter Automation

The reality is clear: seasonal surges are no longer seasonal — they’re a recurring stress test that exposes every inefficiency in your retail warehouse and fulfillment operation. As eCommerce accelerates, and consumer expectations rise, outdated systems can’t keep up with the scale, speed, and complexity now required of modern retail distribution centers.

Relying on static infrastructure and seasonal labor fixes is not only unsustainable — it’s costing businesses revenue, customer trust, and long-term competitiveness.

That’s why more logistics leaders are turning to automated warehouse solutions like Rapyuta ASRS — to move beyond survival mode and into a strategy of proactive growth, precision, and resilience.

By deploying modular, robot-powered Rapyuta ASRS, retail logistics operations benefit from:

- 10x improvement in productivity through goods-to-person automation and intelligent bin delivery

- 2.5x increase in storage efficiency via high-density vertical layouts and smart slotting logic

- Scalable throughput to handle peak volume with fewer staff

- Real-time inventory visibility and seamless WMS/ERP integration

- Phased, low-disruption deployment that fits within existing warehouse layouts

It’s a strategic infrastructure layer purpose-built for the demands of today’s high-volume retail logistics environment. Whether you’re optimizing for this year’s holiday rush or future-proofing your supply chain, Rapyuta ASRS gives your warehouse the ability to scale smarter, move faster, and operate leaner.

Falling short of SLA targets during peak season?

See how Rapyuta ASRS delivers 10× throughput for high-volume retail fulfillment — with fewer errors, faster picking, and smarter scaling.