The Growing Challenges in Warehouse Automation

Warehouses today are under immense pressure. Labor shortages, rising operational costs, and the need for greater efficiency have made automation an essential—not optional—consideration. However, traditional Automated Storage and Retrieval Systems (ASRS) come with significant barriers.

High capital expenditure, rigid designs, and lengthy implementation times often deter companies from adopting these systems.

While ASRS solutions promise efficiency, many fail to provide the flexibility and scalability that modern warehouses require. Most systems require major infrastructure changes, forcing businesses to invest heavily in a solution that may not fully align with their evolving needs.

This is where Rapyuta ASRS redefines warehouse automation.

The Challenges with Conventional ASRS

While ASRS has been widely recognized for improving warehouse efficiency, traditional systems come with well-documented challenges:

- High Initial Investment – Many ASRS providers require multi-million-dollar commitments, making automation a high-risk decision.

- Lack of Flexibility – Conventional ASRS solutions often necessitate permanent layout changes that cannot be easily modified as business requirements evolve.

- Scalability Constraints – Expanding or modifying traditional ASRS often results in additional complexities and costs, limiting adaptability to seasonal or fluctuating demand.

- Integration Challenges – Legacy systems frequently struggle to integrate seamlessly with existing Warehouse Management Systems (WMS) and Enterprise Resource Planning (ERP) software.

Given these challenges, businesses need a more adaptable, scalable, and cost-effective approach to warehouse automation.

Rapyuta ASRS: A Smarter Approach to Automation

Rapyuta ASRS is designed to eliminate the common barriers associated with traditional automation, providing a system that is:

- Adaptive – Configurable to fit existing warehouse layouts without major structural changes.

- Scalable – Businesses can expand or adjust their automation footprint as demand fluctuates.

- Cost-Effective – A modular approach ensures lower upfront investment while delivering rapid ROI.

- Seamlessly Integratable – Designed to work in tandem with existing WMS and ERP systems, ensuring smooth digital integration.

1. Adaptive by Design – Built for Your Warehouse

Unlike conventional ASRS, which dictates warehouse layout and operations, Rapyuta ASRS is designed to integrate into existing infrastructure.

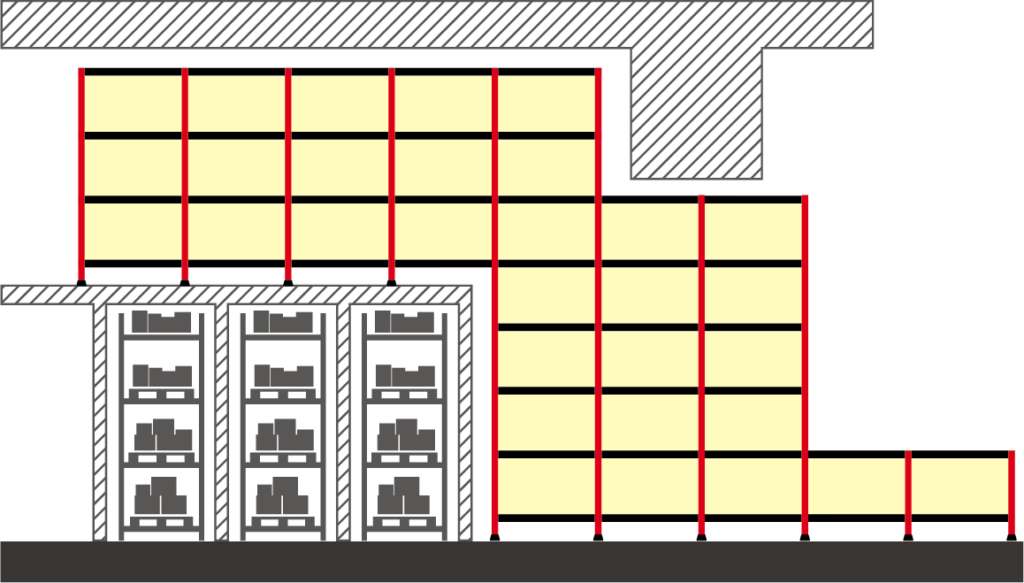

- Modular Construction – The system consists of just three core components, ensuring easy adaptability to different warehouse sizes and configurations.

- No Permanent Layout Changes – The system is fully reconfigurable, allowing businesses to scale up or down based on demand.

- Multi-Workflow Compatibility – Supports high-mix, low-volume SKUs as well as bulk storage, providing operational flexibility.

2. Scalable Without Large Capital Expenditure

One of the most significant barriers to ASRS adoption is the large initial investment required. Rapyuta ASRS overcomes this challenge by offering a modular and incremental implementation approach.

- Start Small, Expand as Needed – Businesses can deploy Rapyuta ASRS in phases, scaling up as operations grow.

- No Disruptive Infrastructure Overhaul – Unlike conventional ASRS, Rapyuta does not require extensive floor excavation, complex conveyor systems, or expensive structural modifications.

- Efficient Space Utilization – The system allows for high-density storage, optimizing warehouse real estate.

3. Cost-Effective Without Compromising Performance

Traditional ASRS solutions often require substantial capital investment, followed by high operational and maintenance costs. Rapyuta ASRS is engineered to offer affordable automation without sacrificing efficiency:

- Lower Capital and Operational Expenses – Leaner hardware, efficient design, and modular deployment reduce overall costs.

- No Hidden Maintenance Fees – Transparent pricing ensures predictable cost structures for long-term planning.

- Optimized Resource Allocation – Reduces dependence on manual labor while ensuring faster order fulfillment and higher accuracy.

4. Seamless Integration with Existing WMS & ERP

A major challenge in adopting ASRS solutions is ensuring smooth integration with existing Warehouse Management Systems (WMS) and Enterprise Resource Planning (ERP) software. Rapyuta ASRS is designed for effortless digital synchronization, enabling real-time warehouse visibility and intelligent automation.

- Integration Acceleration: Rapyuta ASRS seamlessly connects with WMS and ERP platforms, automating inbound, outbound, and inventory management processes. This eliminates manual data entry, reduces errors, and ensures a streamlined workflow.

- Optimized Inventory and Order Fulfillment: By leveraging real-time inventory tracking, the system accurately maps stock using bin IDs and QR codes. This prevents misplaced items, enhances order accuracy, and accelerates fulfillment. Additionally, intelligent batching prioritizes SKU movements, optimizing picking sequences for greater efficiency.

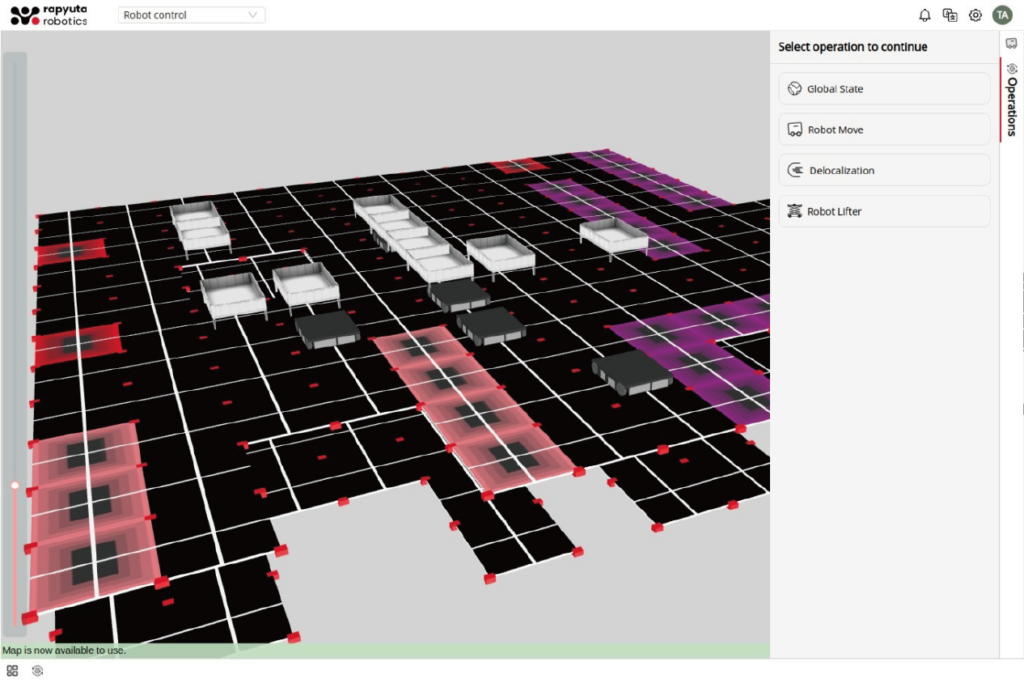

- Advanced Robot Coordination and System Control: The WMS integration provides a real-time digital map to track robots, bins, and floor panels, ensuring optimized picking routes and movement. It also enables smooth collaboration with external automation, such as Pick-Assist AMRs, allowing warehouses to efficiently handle oversized or infrequent items.

- Centralized Command & Control: Warehouse managers can oversee ASRS functions, direct lifters, and monitor robotic operations from a single interface. This level of system control ensures maximum operational stability and efficiency.

Addressing Key Decision-Maker Concerns

Decision-makers evaluating ASRS solutions must consider efficiency, integration, and long-term value. Below are common concerns and how Rapyuta ASRS addresses them:

- Will this work with my existing WMS and ERP?

Yes. Rapyuta ASRS is designed for seamless integration with any modern WMS and ERP system through API-based connectivity. This ensures smooth data exchange, eliminating manual interventions and reducing the risk of errors. Additionally, our integration process is structured for minimal disruption, allowing businesses to maintain operations while transitioning.

- How does it compare in terms of storage density?

Rapyuta ASRS optimizes warehouse space with high-density bin configurations, supporting up to 9 storage levels within a compact footprint. By leveraging vertical space efficiently, warehouses can store up to 50% more inventory compared to traditional racking systems. This translates to greater SKU accessibility, improved space utilization, and reduced dependency on facility expansion.

- What about long-term support and reliability?

The system is built with remote monitoring, real-time diagnostics, and predictive maintenance capabilities to proactively identify potential issues before they disrupt operations. Our 24/7 support ensures that businesses experience minimal downtime, while automated fault detection enhances long-term system reliability, reducing maintenance costs over time.

- Is the system future-proof?

Yes. Rapyuta ASRS is designed for scalability, allowing businesses to expand storage and retrieval capacity incrementally. As order volumes grow, additional storage modules can be seamlessly integrated without reconfiguring the entire warehouse layout. This ensures adaptability for changing operational needs, whether it’s handling seasonal surges or expanding to accommodate business growth.

A Future-Proof Approach to Warehouse Automation

For warehouse operators and supply chain decision-makers, automation is no longer a question of if, but when and how. Rapyuta ASRS provides a solution that is:

✔ Adaptive – Designed to complement and enhance existing warehouse operations.

✔ Scalable – Flexible enough to grow alongside business demands.

✔ Cost-Effective – Removes financial and operational barriers to automation.

Next Steps: Optimizing Warehouse Automation

With the rapid evolution of supply chain demands, warehouse automation must be agile, efficient, and financially viable. Rapyuta ASRS offers a solution that ensures operational resilience and long-term value.

To learn more about how Rapyuta ASRS can optimize your warehouse operations, contact us today for a consultation.