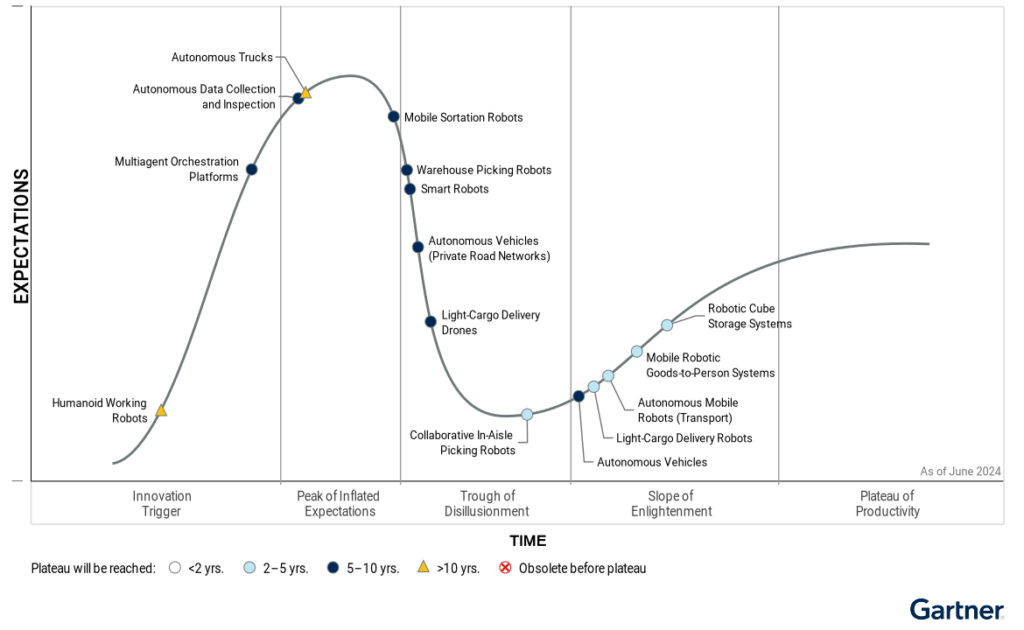

Gartner’s latest Hype Cycle for Mobile Robots and Drones reveals a growing trend: advanced mobile robotics are quickly becoming indispensable in supply chain operations. Technologies such as autonomous mobile robots (AMRs) for transport, collaborative picking robots, and goods-to-person systems are maturing rapidly, signaling a shift toward more efficient, scalable, and intelligent warehouse management solutions.

Key Findings from Gartner’s Hype Cycle

1. Evolving Supply Chain Automation

As organizations aim to enhance logistics, automation, and workforce augmentation, mobile robots play a central role in achieving these objectives.

- Technologies like Pick Assist AMRs and drones are advancing beyond the “Trough of Disillusionment,” entering the “Slope of Enlightenment,” where their benefits are widely understood and embraced.

- For warehouse operations, this means greater adoption of robots that not only handle repetitive tasks but also supplement human workers for faster and more accurate processes.

2. AI and Automation on the Rise

Solutions leveraging AI-enabled vision and RFID technology, such as indoor-flying drones and mobile robots, are increasingly used for inventory management and inspection. These solutions address critical challenges, including safety and efficiency in hard-to-reach areas, while paving the way for autonomous operations.

3. Humanoid Robots Entering the Innovation Trigger Phase

While mainstream adoption of humanoid robots in supply chains remains a decade away, their development signals significant progress in automation. Powered by AI, humanoid robots aim to replicate human adaptability for dynamic warehouse tasks, potentially transforming supply chain workflows in the future.

What to Expect from Warehouse Picking Robots in the Coming Years: A Positive Outlook

As warehouses grapple with increasing customer demands, labor shortages, and the need for speed and accuracy in order fulfillment, Pick Assist AMRs have emerged as a transformative solution. These advanced robotic systems are redefining how warehouses operate by automating repetitive tasks, enhancing worker productivity, and driving efficiency. Here’s what we can expect from this technology in the coming years and why the future looks promising:

1. Widespread Adoption Driven by Scalability

Pick Assist AMRs are on a clear path toward mainstream adoption. As the technology matures, businesses will benefit from:

- Scalable Solutions: Robots will become more flexible to suit warehouses of all sizes, from small e-commerce hubs to large 3PL distribution centers.

- Cost Reductions: Advancements in robotics hardware and software will lower upfront costs, making these solutions more accessible to a wider range of companies.

- Global Implementation: Warehouses worldwide will adopt these systems, creating new benchmarks for supply chain efficiency.

2. Increased Efficiency and Productivity

Pick Assist AMRs are designed to reduce inefficiencies caused by manual processes:

- Faster Picking Rates: Robots can reduce the time taken to locate and retrieve items, ensuring faster order fulfillment.

- Higher Productivity: Robots can work tirelessly, 24/7, handling repetitive tasks without fatigue, enabling warehouses to handle peak-season volumes seamlessly.

- Error Reduction: With precise sensors and intelligent algorithms, these robots will significantly reduce picking errors, improving customer satisfaction and reducing return rates.

3. Collaboration Between Robots and Humans

Rather than replacing human workers, Pick Assist AMRs will enhance their productivity by:

- Taking Over Repetitive Tasks: Robots will handle mundane, physically demanding jobs like transporting items, allowing workers to focus on higher-value tasks.

- Human-Robot Collaboration: We’ll see the rise of hybrid workflows where robots and humans work together to achieve higher efficiency and faster order fulfillment.

This collaborative model will lead to safer working conditions, reduced physical strain, and increased job satisfaction for workers.

4. Advanced Integration with Warehouse Management Systems (WMS)

Pick Assist AMRs seamlessly integrate with Warehouse Management Systems and other automation tools. This integration will enable:

- Dynamic Task Allocation: Robots will adapt to real-time changes in order priority and warehouse operations.

- Enhanced Data Analytics: The robots will generate valuable insights into warehouse performance, helping managers make informed decisions and optimize workflows.

5. Overcoming Labor Challenges

The global warehouse industry is struggling with labor shortages, especially for physically demanding jobs. In the coming years, robots will bridge this gap by:

- Reducing Dependency on Manual Labor: Robots can handle picking and transportation tasks traditionally done by humans, addressing the labor supply-demand imbalance.

- Supporting Seasonal Demand: During peak seasons, robots can scale operations without requiring additional hiring or training.

6. Driving Innovation in Supply Chain Automation

Pick Assist AMRs are a gateway to broader supply chain automation. As they evolve, we can expect:

- Integration with Other Robotics: For example, mobile robots working with drones for inventory counting or autonomous trucks for transportation.

- AI-Powered Decision-Making: Future robots will leverage AI to make smarter decisions, such as optimizing picking routes or anticipating inventory needs.

Rapyuta PA-AMRs: Your Ideal Partner in Warehouse Automation

Rapyuta Robotics offers Pick-Assist AMRs (PA-AMRs) that not only align with the trends highlighted in the Hype Cycle but also address key operational challenges faced by warehouses today.

Why Rapyuta PA-AMRs Are the Best Choice

1. Seamless Navigation and Autonomous Operation

Using advanced technologies like LiDAR, cameras, and AI-powered navigation, Rapyuta PA-AMRs move efficiently through complex warehouse environments. These robots operate without guide tape, adapting dynamically to obstacles and changes in real time.

2. Enhanced Collaboration with Humans

- Simplified Training: New employees can quickly adapt to picking tasks with guidance from the robot, reducing onboarding time.

- Workforce Augmentation: PA-AMRs handle repetitive and strenuous tasks, allowing associates to focus on more value-driven activities.

3. Integration with Existing Systems

PA-AMRs connect seamlessly with Warehouse Management Systems (WMS) and ERP platforms, enabling real-time data sharing for optimized operations.

4. Key Features

- Intelligent Route Planning: Optimizes picking routes to minimize downtime.

- Error-Free Operations: AI capabilities reduce human errors, ensuring accurate and efficient processes.

- Flexibility and Scalability: Easily adjustable to meet seasonal demands without significant layout modifications.

5. Safety Measures

- Collision Avoidance: Sensors ensure safe navigation around associates and obstacles.

- Emergency Stop Mechanisms: Swiftly halt operations during unforeseen events.

The Competitive Edge of Rapyuta PA-AMRs

Rapyuta Robotics stands out in the rapidly growing robotics market by delivering solutions that are:

- Cost-Effective: Through flexible pricing models like Robots-as-a-Service (RaaS), businesses can scale operations without heavy upfront costs.

- Reliable: 24/7 support ensures minimal downtime and maximum efficiency.

- Future-Ready: As technology evolves, Rapyuta PA-AMRs continue to adapt, ensuring long-term value for warehouses.

Conclusion

With rapid advancements in robotics technology and increasing demand for supply chain automation, warehouse picking robots will become a standard feature in warehouses globally. Businesses that embrace this technology will not only gain a competitive edge but also create sustainable, resilient, and future-ready operations.

The future of warehouse picking robots is bright—and it’s a future where humans and robots work together to achieve unparalleled efficiency and success.

Ready to transform your picking operations?

Contact Rapyuta Robotics to explore how PA-AMRs can revolutionize your warehouse and ensure you stay ahead in the evolving logistics landscape.