In the ever-evolving world of warehouse logistics, keeping up with demand while minimizing costs is a balancing act. Enter Mobile Robots as a Service (RaaS), a model where you subscribe to a service that provides autonomous mobile robots tailored to your operational needs. RaaS offers a dynamic approach to integrating these robots into your operations without the hefty upfront costs typically associated with automation.

What is RaaS?

Think of it as leasing advanced technology tailored to your needs. With RaaS, you’re not buying robots outright. Instead, you’re subscribing to a service that scales with your operational demands. This approach ensures you only pay for productivity gains and efficiency boosts you achieve.

A Closer Look at RaaS

Imagine you need a fleet of robots to manage increased warehouse activity during peak seasons. Purchasing these robots usually requires a substantial upfront investment and ongoing maintenance costs. With RaaS, you can lease these robots for the specific period you need them, adjusting the number based on your operational demands. If you experience a surge in orders during the holiday season, you can temporarily increase your robotic workforce without a long-term financial commitment.

RaaS includes comprehensive support and updates, ensuring your technology remains state-of-the-art without additional costs. The subscription model allows you to stay flexible, scaling your operations smoothly as demand fluctuates. By paying for performance, RaaS ensures your investment aligns directly with productivity improvements and efficiency gains, making it a financially savvy choice for dynamic warehouse environments.

This model also liberates your capital, allowing you to allocate it to other business areas, fostering growth and innovation without the financial strain of purchasing and maintaining a fleet of autonomous mobile robots. RaaS transforms how businesses approach automation. It provides a scalable, cost-effective, and efficient solution tailored to their unique needs, relieving you of large upfront investments’ financial burden and uncertainty.

ROI Guarantee

Rapyuta Robotics’ recent press release highlights a groundbreaking ROI guarantee. This promise ensures that your investment in autonomous mobile robots translates directly into measurable returns. It mitigates the financial risks traditionally associated with adopting new technologies, offering your business a clear and tangible benefit.

A New Level of Assurance

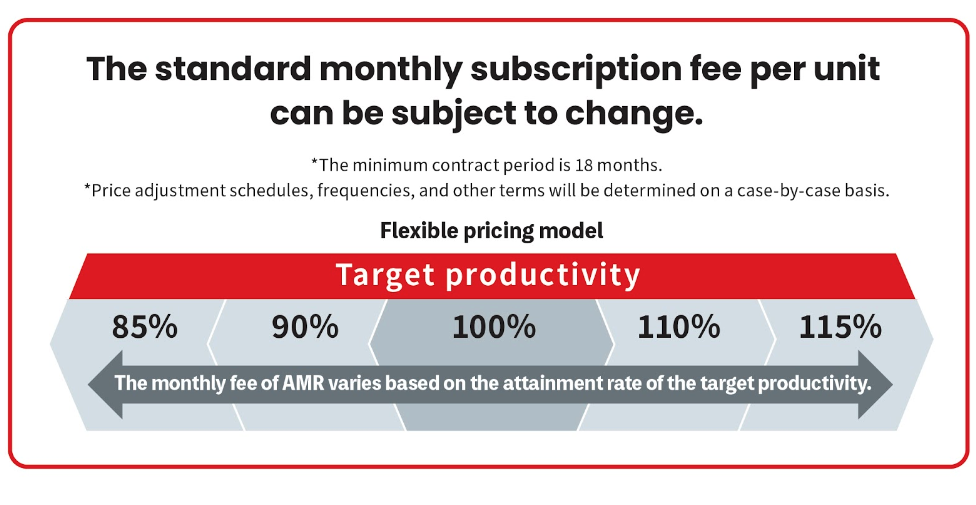

With this ROI guarantee, Rapyuta Robotics pledges that deploying their autonomous mobile robots will yield measurable productivity improvements. If productivity falls short, subscription fees are reduced to ensure that you achieve the desired ROI. This commitment significantly reduces the risk of integrating new technology into your operations, providing peace of mind that your investment will pay off.

Flexibility in Deployment

In addition to the ROI guarantee, Rapyuta Robotics offers flexible pricing plans that cater to your business’s unique needs. Whether you need to scale up during peak seasons or reduce your fleet during slower periods, these plans ensure you can easily adjust as needed. This flexibility ensures that your investment in Mobile Industrial Robots (AMRs) always aligns with your operational requirements, making it easier to manage costs and maximize efficiency.

Why Choose RaaS?

- Scale your fleet of robots up or down based on real-time needs.

- Avoid the significant capital expenditure of purchasing robots outright.

- Pay for performance, ensuring your investment yields tangible benefits.

- Stay ahead with the latest in Pick Assist Robots “PA-AMR” technology.

By choosing RaaS, you’re investing in cutting-edge technology and a service model that prioritizes your business’s financial and operational health. This approach ensures you remain competitive, efficient, and adaptive to market demands while minimizing financial risk.

Boosting Efficiency with AMRs

Autonomous mobile robots (AMRs), especially Pick Assist Robots, are revolutionizing warehouse operations. By handling repetitive and time-consuming tasks, these robots free up human workers for more strategic roles, enhancing overall productivity. The immediate efficiency gains from integrating AMRs include quicker order fulfillment and reduced labor costs.

Enhanced Productivity

By automating tasks such as picking and sorting, Pick Assist Robots significantly reduce the time required to process orders. This automation accelerates operations and ensures greater accuracy, reducing errors commonly associated with manual handling. Consequently, human workers are empowered to focus on more complex and value-added activities, such as inventory management and quality control, fostering a more dynamic and fulfilling work environment.

Cost Savings

A significant benefit of implementing AMRs is the reduction in labor costs. With robots taking over monotonous tasks, the need for temporary or seasonal workers decreases, leading to substantial savings. Additionally, the precision of AMRs minimizes the mis-pick errors, further lowering operational expenses.

Operational Expenditure (Opex) Savings:

Labor Costs: By automating the picking operations, Rapyuta PA-AMRs reduces the need for temporary or seasonal workers, leading to substantial labor cost savings. Companies can allocate human resources to more strategic roles, optimizing workforce efficiency.

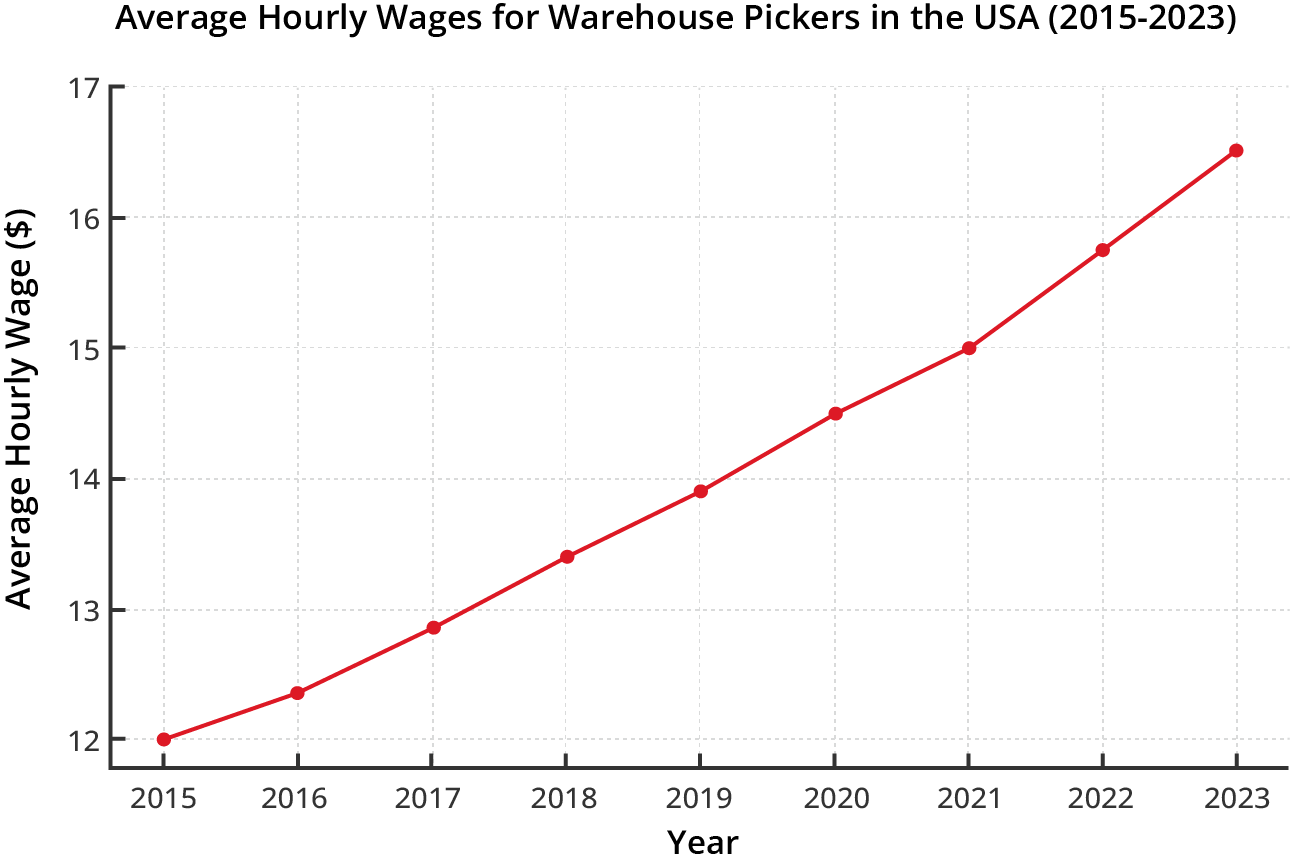

Wage Increases: With the rising cost of labor, Rapyuta PA-AMRs provide a cost-effective alternative, mitigating the financial impact of wage hikes and allowing businesses to maintain competitive pricing.

Low Capital Expenditure (Capex):

No Upfront Purchase: Rapyuta Robotics offers flexible financing options, including leasing and subscription models, eliminating the need for substantial upfront investments. This makes it easier for businesses to adopt cutting-edge technology without heavy initial capital outlay.

Low Integration Fee: Rapyuta PA-AMRs are designed for quick and seamless integration into existing systems, resulting in minimal integration fees. The ease of deployment reduces the initial financial burden and accelerates the return on investment (ROI).

Example Analysis of ROI Recovery

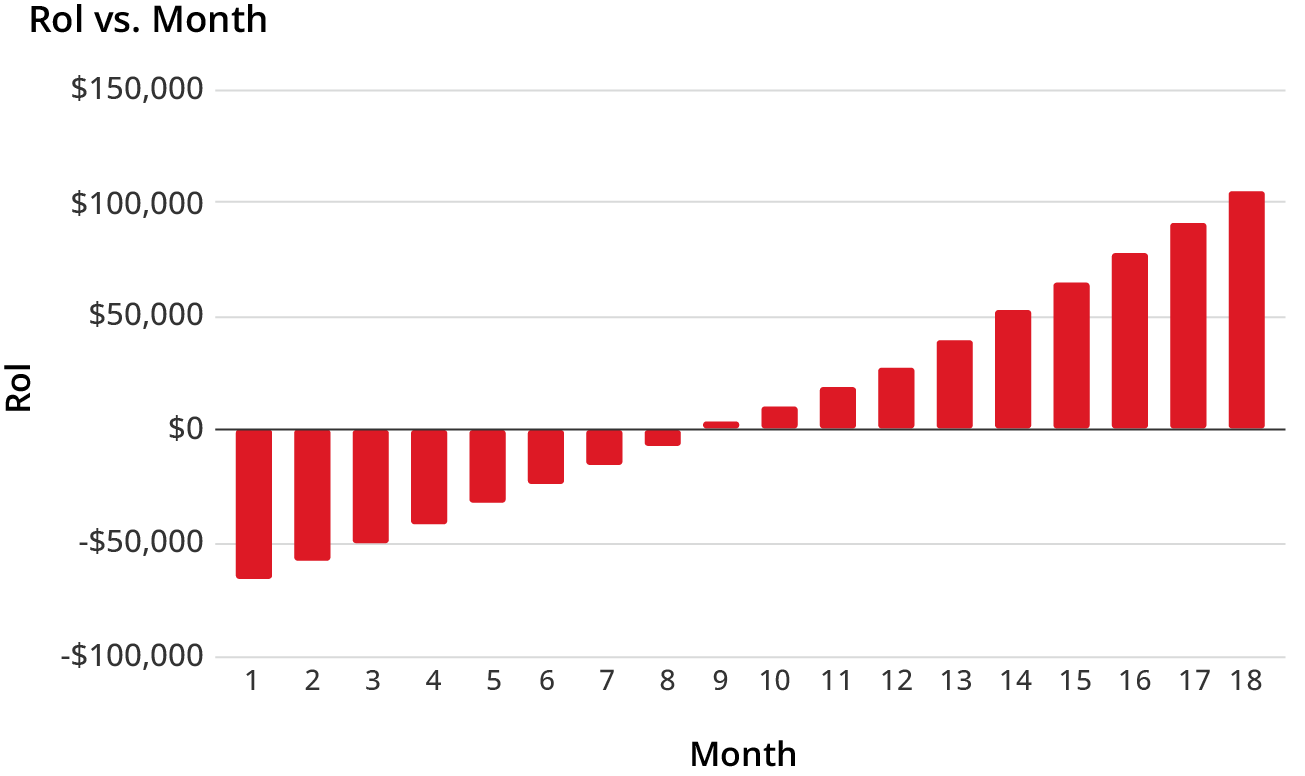

This example demonstrates the financial impact and ROI recovery associated with integrating PA-AMRs into operations. It includes initial set-up costs, monthly savings, and ROI calculations over an 18-month period.

ROI Over 18 Months:

The ROI is calculated by taking into account the initial $75,000 one-time setup fee for installing 13 Rapyuta PA-AMRs at $1000 per month resulting in an ongoing monthly savings of $8,526.

Insights:

- This example shows how ROI initially reflects a negative return due to the high upfront investment but becomes positive by the 9th month.

- By the 18th month, the cumulative ROI reached $104,737, demonstrating a substantial return on the initial investment.

Curious about the full breakdown? Reach out to our expert.

Seamless Integration

Rapyuta Robotics makes the transition to RaaS effortless. Their platform ensures compatibility with existing systems, providing a smooth integration process that minimizes downtime. Plus, with ongoing support and updates, your robots stay at the cutting edge of technology.

Minimal Disruption

Rapyuta Robotics’ integration process is designed to fit seamlessly with your current warehouse management systems. This compatibility reduces the need for extensive reconfiguration, ensuring your operations continue with minimal disruption. The platform’s user-friendly interface allows for quick training and adoption, enabling your team to leverage the benefits of AMRs immediately.

Peak Season

Enhanced efficiency is not merely a daily or weekly concern but a year-round imperative. Rapyuta Robotics’ Pick Assist Automated Mobile Robots (PA-AMRs) are specifically designed to offer optimal scalability for distribution warehouses, particularly during peak seasons.

The swift integration of PA-AMRs markedly reduces reliance on labor during periods of heightened demand. Rapyuta Robotics empowers warehouses with the flexibility to quickly expand their robotic workforce, such as by adding 10 robots to meet increased demand.

What further sets Rapyuta Robotics apart is their seamless capability to scale down operations once peak seasons recede, ensuring sustained efficiency and cost-effectiveness throughout the year. This adaptability not only enhances operational agility but also maximizes resource utilization, establishing Rapyuta Robotics’ AMRs as a strategic solution for managing fluctuating demand in distribution logistics.

With minimal disruption and seamless integration, warehouse operations can effortlessly scale up and down, highlighting the simplicity and efficacy of adopting Rapyuta Robotics’ AMRs.

Continuous Improvement

With Rapyuta Robotics, you receive ongoing support and regular updates, ensuring your robots always utilize the latest technology. This continuous improvement guarantees that your AMRs remain efficient and effective, adapting to new challenges and maintaining high productivity levels. The company’s commitment to support means that any issues are promptly addressed, ensuring smooth and uninterrupted operations. This seamless integration and continuous improvement mean that your operations are future-proofed and ready to adapt to the evolving industry landscape.

By integrating AMRs through Rapyuta Robotics’ RaaS model, warehouses can achieve higher efficiency, cost savings, and operational excellence, positioning themselves at the forefront of industry innovation.

Ready to Raise Your ROI?

Learn more about the benefits of RaaS and how it can revolutionize your warehouse operations by getting in touch with us!