Greenfield vs. Brownfield

Traditionally, automated storage and retrieval systems (ASRS) were primarily implemented in newly constructed warehouses or factories. However, dynamic and flexible solutions like the Rapyuta ASRS are now emerging, designed to integrate seamlessly into existing facilities.

In industries such as manufacturing, warehousing, and infrastructure development, the terms “Greenfield” and “Brownfield” are frequently used. . Today, these terms are widely applied across various fields: “Greenfield” signifies a blank slate or a fresh start, whereas “Brownfield” refers to existing facilities, systems, or legacy infrastructure.

This article highlights key considerations for selecting an ASRS solution, such as the Rapyuta ASRS, that can be deployed not only in Greenfield projects but also in Brownfield environments (existing sites).

Point 1: Can the Layout Fit the Site’s Shape?

Automated storage and retrieval systems (ASRS) inevitably require a certain amount of space. When introducing an ASRS as part of a Brownfield project in an existing site, it’s essential to design the layout while considering various constraints such as the placement of existing equipmentthe flow of people and goods, on-site operations, and columns and beams.

Today’s ASRS solutions come in a variety of formats, with significant differences in layout flexibility. As mentioned above, assessing whether a system can adapt its layout to the internal shape of the building, existing equipment, and operations is relatively straightforward. Below, we delve into additional evaluation points to consider.

The Prerequisites for Maximizing Storage Efficiency: Effective Space Utilization

One of the primary reasons many customers choose to implement an ASRS is to make better use of available space. Generally, the following three types of space inefficiencies hinder optimal utilization:

- Flat Space: Wasted space visible in floor plans, such as unused areas or excessive aisle space.

- Vertical Space: Wasted vertical space, such as the gap between the top of storage racks and the ceiling.

- Within Shelves/Bins: Space inefficiency within shelves caused by reduced inventory levels or partially filled racks.

Most ASRS products are designed to reduce all three types of space inefficiencies to varying degrees. However, it’s crucial to consider whether there is a significant gap between theoretical storage efficiency (when the ASRS is ideally positioned) and real-world storage efficiency (when the ASRS layout is adjusted to fit the actual site’s shape).

Some ASRS solutions are designed to be installed as neat rectangular structures or require specific shelving configurations based on predefined constraints. These may not always fit well with unique internal layouts of existing sites. For instance, if the space where the ASRS will be installed has no obstacles like columns, beams, or mezzanine floors, it’s likely that the system can be installed as intended. However, when such obstacles exist, the gap between the ideal design and the real-world application can become a significant barrier to achieving the desired storage capacity and efficiency.

Rapyuta ASRS perfectly fits sites with columns, beams, mezzanines, and other structural features.

The Modular Automated Storage and Retrieval System

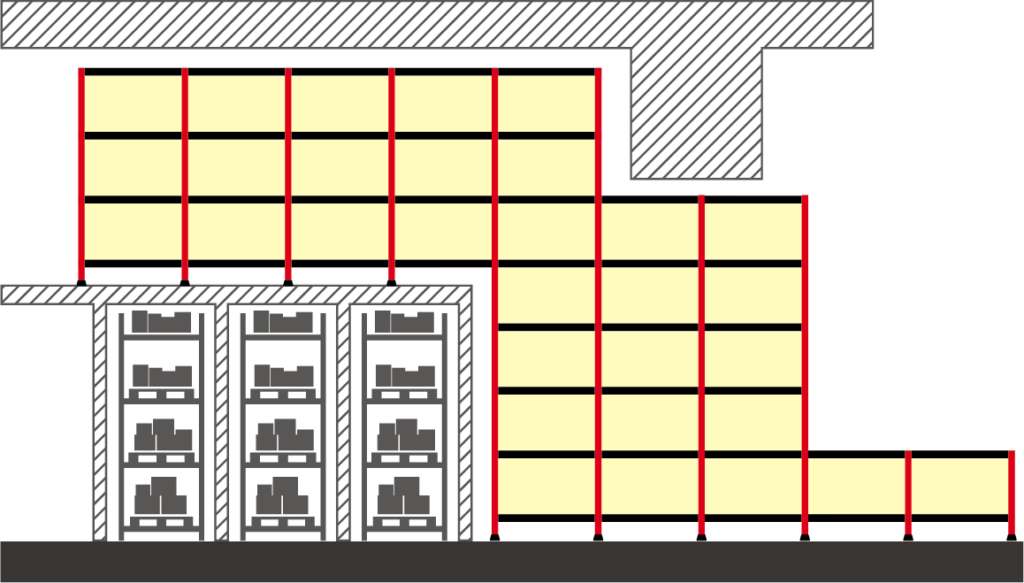

Rapyuta ASRS features a unique modular design that allows layouts to adapt to both the horizontal and vertical dimensions of existing facilities. This not only enables efficiency within the automated system itself but also improves the overall storage efficiency of the entire warehouse or factory space.

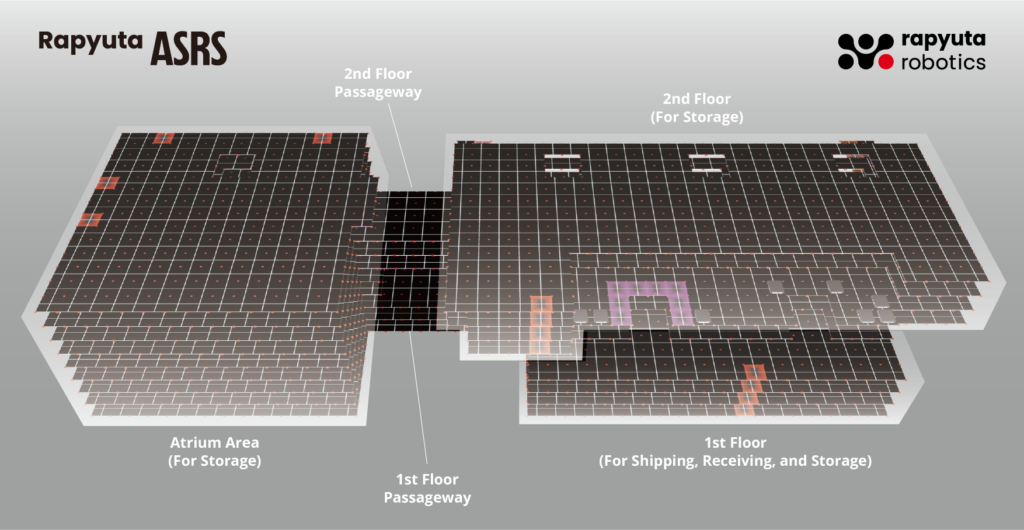

Cross-Floor and Zone Installation

One standout feature of Rapyuta ASRS is its ability to span multiple floors and operate as a single automated system. At the facility of HobbyLink Japan Co., Ltd., which began operations in July 2024, Rapyuta ASRS was installed across the first and second floors of a standard warehouse with a ceiling height of approximately 2.7 meters, as well as in an adjacent open space. By connecting these installations, the system forms a U-shaped configuration when viewed in cross-section, functioning as a single automated warehouse.

Flexibility of Rapyuta ASRS at HobbyLink Japan’s site in Tochigi, Japan.

Point 2: Floor Conditions and Levels

When considering the implementation of an automated warehouse, the condition of the site’s floor is an often-overlooked factor. Many ASRS systems require floor preparation, including anchor construction, and ideally need flat, even surfaces without any irregularities. Some systems have particularly stringent requirements regarding floor conditions. If the site does not meet these requirements, additional floorwork may be necessary, incurring extra costs and time.

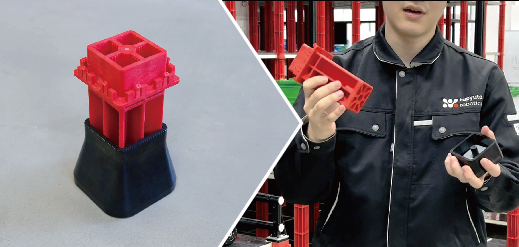

Rapyuta ASRS, however, was designed from the outset with the intention of being installed in existing warehouses and factories. Its base modules are engineered to be more forgiving of floor conditions, reducing the need for extensive floor preparation and lowering both costs and installation time.

Rapyuta ASRS adjusts levels by inserting metal shims into the rubber boot of its base blocks.

The base blocks of the Rapyuta ASRS are equipped with rubber boots, and as shown in the image above, metal shims are inserted into the rubber boots to adjust the floor level. This mechanism allows the system to accommodate floor level variations within ±20mm across the entire installation area, providing an exceptional level of floor adaptability for an automated storage and retrieval system.

Point 3: Ceiling Height

One of the main advantages of ASRS is their ability to effectively utilize vertical space. In some cases, mezzanine floors further reduce the available height.

In these situations, the focus shifts from “whether the system can be installed” to “whether the ROI (Return on Investment) makes sense.” One of thekeys to ASRS is maximizing the use of vertical and horizontal space to achieve equal or greater productivity with fewer workers. However, in sites with low ceilings, the storage capacity is inherently limited, making it critical to evaluate whether the investment can deliver sufficient benefits or be recouped within the company’s required timeframe.

The Rapyuta ASRS, with its unique modularity, offers flexible layouts and can be installed even in spaces with ceiling heights under 3 meters. However, the key consideration remains the ROI—how much benefit the customer can gain from the investment.

For height limits, the system can stack up to 20 levels (using standard 630mm poles), based on structural strength. In case of a request for anoverly tall, narrow configurations, installation proposals are tailored to consider its structural stability and balance, taking into account factors like the site’s floor load capacity.

Point 4: Power Supply

Most ASRS systems operate on three-phase 230/480Vpower, as typically used in factories. If the existing site does not have a three-phase 230/480V power supply, additional electrical work will be required, including the installation of power panels. In addition to voltage compatibility, power capacity must also be considered, often necessitating additional electrical work for the site. In some cases, this includes connecting to the outdoor main line or renegotiating contracts with the power company, impacting both initial and ongoing costs.

Unlike many other ASRS systems, the Rapyuta ASRS runs on a standard single-phase 120V power supply, similar to a household outlet. While additional work to expand power capacity may still be necessary, using single-phase 120V offers significant cost advantages in terms of both initial installation and long-term operational expenses compared to three-phase systems.

Point 5: Earthquake Countermeasures

Japan has a unique concern—earthquakes. As a Japanese company, Rapyuta Robotics prioritized earthquake resistance during the development of its Modular Automated Storage and Retrieval System, the Rapyuta ASRS.

Traditionally, earthquake countermeasures involved enhancing the rigidity of the structure to resist seismic force, an approach known as “seismic resistance.” Reinforcement through braces at column-beam intersections is a well-known example of seismic retrofitting.

However, for ASRS, the goods stored within the structure are often as important, if not more so, than the structure itself. To address this, Rapyuta ASRS incorporates “seismic isolation,” similar to high-rise residential towers. By allowing the structure to sway and absorb seismic energy, this approach not only protects the ASRS itself but also safeguards the stored goods. This perspective highlights the unique considerations of a Japanese manufacturer operating in a seismic-prone region.

Rapyuta ASRS features the same seismic isolation design as high-rise towers, prioritizing not only structural integrity but also the protection of goods stored within.

Meet Our Expert

At Rapyuta Robotics, we offer free individual consultations for the implementation of automated warehouses and related warehouse automation solutions. We offer support in selecting the right automation solution based on its features and suitability for your specific operational needs. Please feel free to reach out to us for assistance with implementing automated warehouses or choosing the best warehouse automation solutions.