Customer expectations for rapid delivery and perfect order accuracy have become the norm in eCommerce. With next-day and even same-day shipping now a standard offering, fulfillment centers are under constant pressure to accelerate their order cycle times — from the moment an order is placed to when it’s picked, packed, and shipped.

Traditional warehouses, built around manual labor and rigid workflows, are hitting a ceiling. Bottlenecks in picking and inventory access slow down operations, and scaling up often means higher labor costs, added complexity, and diminishing returns. Automated Storage and Retrieval Systems (AS/RS) present a smarter alternative — combining robotics, high-density storage, and intelligent software to automate repetitive tasks, reduce human error, and reclaim valuable floor space. By rethinking how goods are stored, retrieved, and routed through the warehouse, ASRS enables operations to run faster, leaner, and with greater accuracy.

This is where Rapyuta ASRS stands out — offering a modular, software-driven ASRS built for adaptability and speed. For businesses looking to streamline fulfillment and stay ahead in an increasingly competitive eCommerce environment, the right system can make all the difference.

The Problem: Fulfillment Bottlenecks That Prolong Cycle Time

As eCommerce order volumes grow, many fulfillment centers struggle with bottlenecks that increase cycle time. Manual picking processes are one of the biggest culprits. Workers often spend more time walking to locate items than picking them up. These inefficiencies add up quickly, especially when handling small, frequent, multi-line eCommerce orders.

Traditional warehouse storage systems also fail to scale with growing SKU counts. Most use less than 30% of their vertical capacity. Coupled with inconsistent labor availability and disconnected digital workflows, these gaps cause daily slowdowns and seasonal breakdowns.

Ultimately, the result is an average order cycle time of 8–12 minutes or more — far too slow for the speed that modern eCommerce demands.

Challenges in eCommerce Fulfillment Operations

eCommerce fulfillment is fast-moving, SKU-dense, and highly sensitive to delivery time. Below are six real-world challenges that fulfillment centers face, many of which mandate the need for an ASRS solution.

1. Long Walking and Retrieval Times

Manual picking requires extensive travel within the warehouse. Workers may spend over 50% of their time just walking between shelves, which adds no value to the order and directly extends cycle time.

2. Limited Storage Density

Traditional racking systems often fail to utilize vertical space effectively. As SKU counts grow, these systems become cramped, disorganized, and hard to scale without physical expansion.

3. Labor Dependency and Shortages

Warehouse operations often rely heavily on manual labor — but labor availability is increasingly volatile. High turnover and rising costs make it hard to maintain consistent staffing, especially during peak demand.

4. Order Accuracy Issues

Human error in picking, sorting, or packaging leads to mis-ships, returns, and costly rework. This not only extends the fulfillment cycle but also affects customer satisfaction and operational KPIs.

5. Poor System Integration

When receiving, storage, picking, and shipping systems are not seamlessly connected, delays and inefficiencies multiply. Without real-time synchronization, data gaps can lead to missed inventory, incorrect orders, and processing lags.

6. Inflexibility During Peak Volume

Traditional systems struggle to scale in response to seasonal or promotional spikes in order volume. Without automation, fulfillment centers must rely on hiring temporary labor, which brings its own training and productivity challenges.

What is ASRS and why is it critical in eCommerce fulfillment?

ASRS (Automated Storage and Retrieval Systems) automates the storage and picking of goods using robotics and software. In eCommerce, ASRS systems are essential for handling high SKU volumes, reducing pick times, and meeting rapid delivery expectations.

How Rapyuta ASRS Solves These Challenges

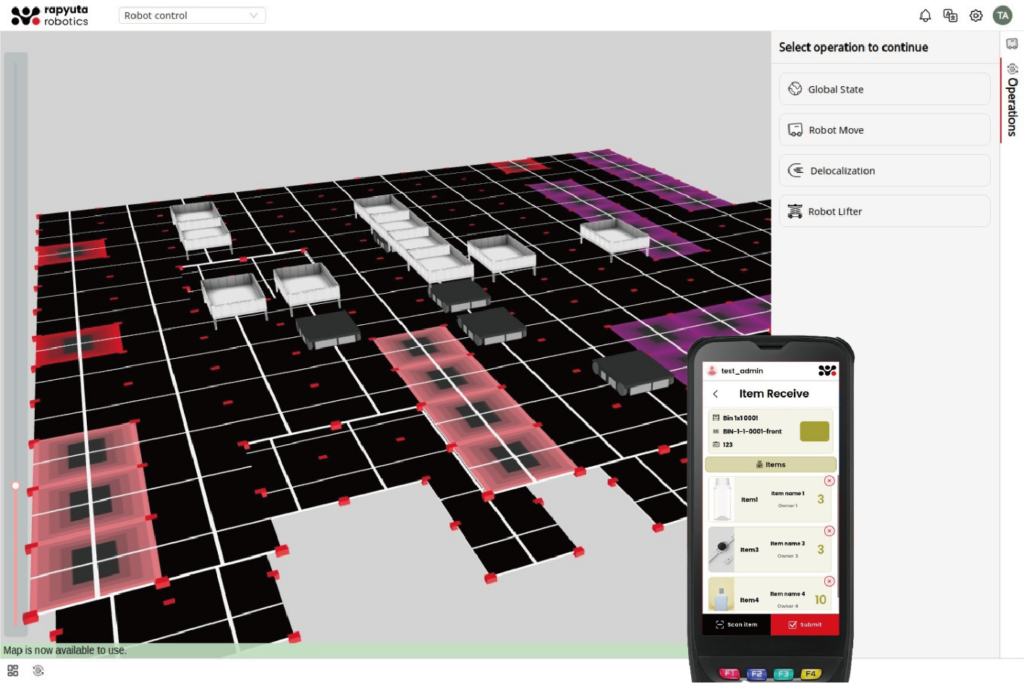

The Rapyuta ASRS was built to solve the operational problems that plague traditional eCommerce fulfillment centers. It combines robotic automation, software integration, and scalable hardware in one unified system.

1. Autonomous Robotic Bin Retrieval

Rapyuta ASRS internal transport robots travel at speeds of up to 2.5 m/s and can perform 138 bin retrievals per hour. These robots use mecanum wheels for omnidirectional movement and are managed by a multi-robot coordination engine that optimizes routing in real time.

As a result, bins are delivered directly to pick stations without human travel, cutting pick time and enabling around-the-clock operations.

How do ASRS robots improve picking efficiency in eCommerce?

ASRS robots reduce walking time by autonomously delivering bins to pick stations. This increases pick speed, accuracy, and consistency — ideal for high-volume, fast-moving eCommerce fulfillment environments.

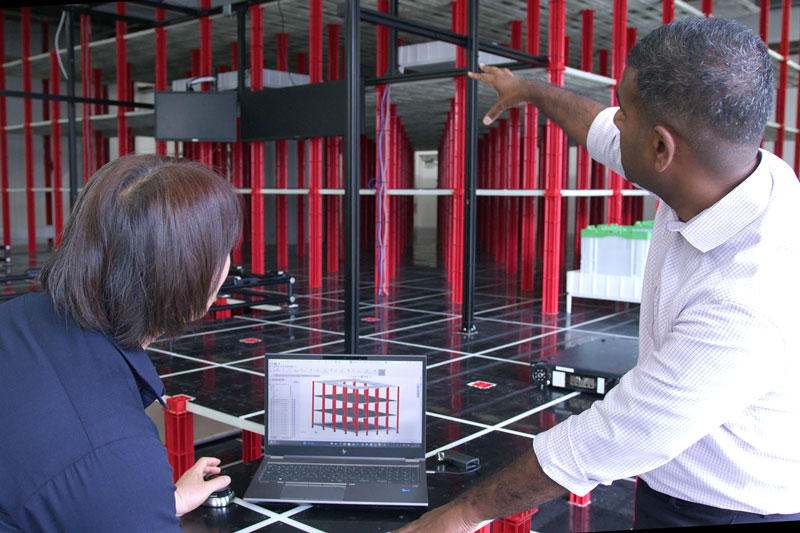

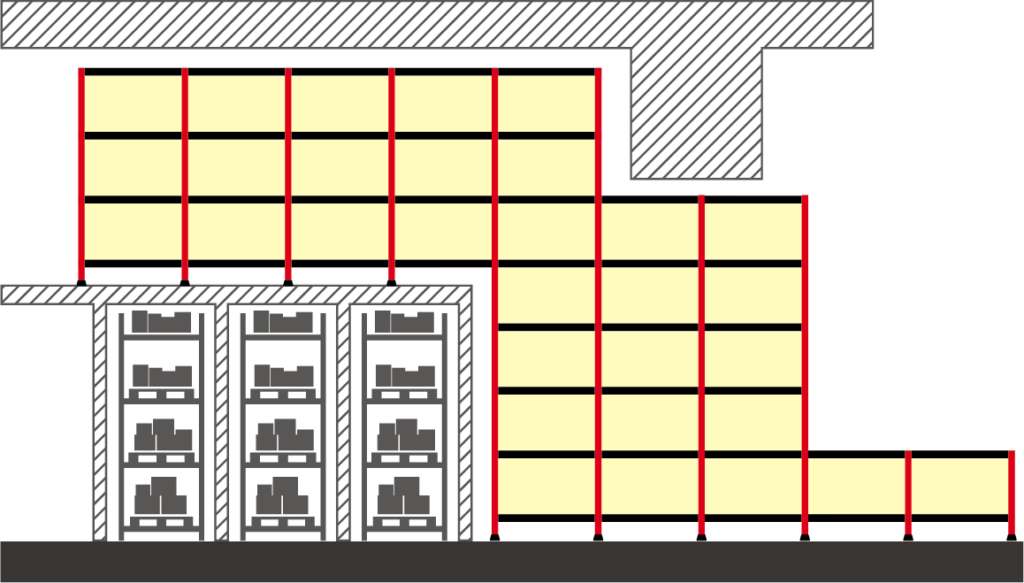

2. High-Density, Modular Storage Design

The Rapyuta ASRS features a flexible modular racking system that allows the configuration with up to 7 or 9 levels—not as a limit, but as flexible design options to suit the needs. Each square meter can support loads of up to 715 kg, and the structure is anchorless for flexible deployment.

This allows eCommerce businesses to store significantly more inventory in the same footprint, while also adapting layouts as SKU volumes change.

Rapyuta ASRS installs without bolting or concrete anchoring — even in odd-shaped buildings, multi-floor facilities, or retrofit environments

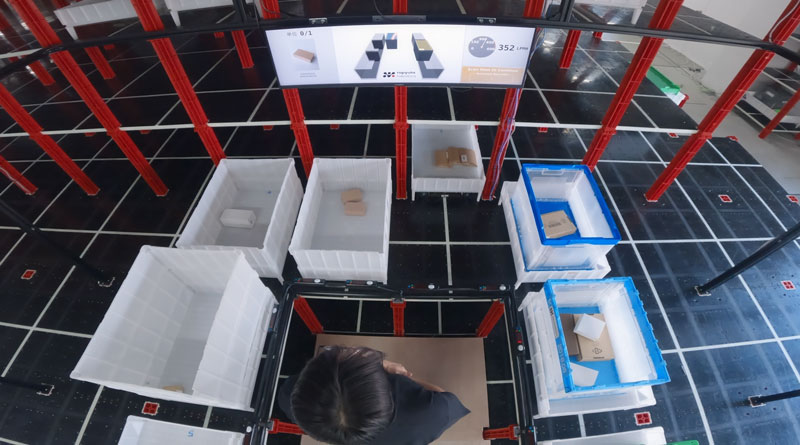

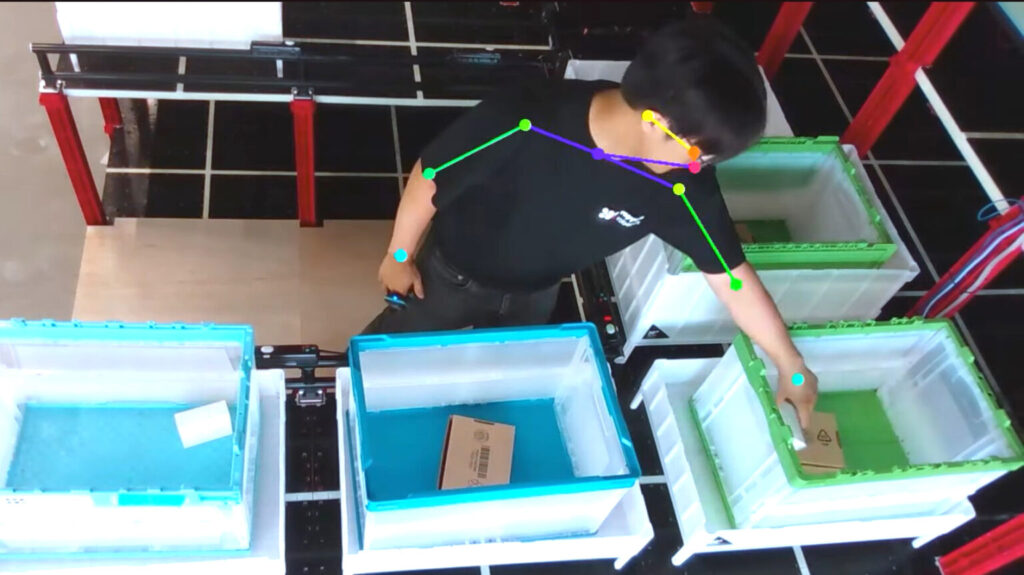

3. Ergonomic, Multi-Bin Picking Stations

Rapyuta’s U-shaped picking stations support up to 8 active bins. Pickers remain stationary while visual aids (projectors, LED indicators, monitors) guide them through tasks. The system is equipped with:

- Motion sensors to detect pick actions

- DAP buttons to confirm task completion

- Live productivity metrics for supervisors

This setup dramatically reduces pick time, lowers fatigue, and ensures consistent output across operators.

4. Labor Optimization and Error Prevention

Rapyuta ASRS reduces dependency on skilled labor by guiding pickers step-by-step, regardless of their language or experience. It also:

- Lowers labor requirements by up to 30%

- Uses AI-powered cameras and sensors to detect errors before they occur

- Prevents the next bin from arriving until current picks are confirmed

This is especially important in eCommerce, where the accuracy of small, diverse orders can make or break the customer experience.

Can ASRS reduce labor costs in eCommerce fulfillment centers?

Yes. Rapyuta ASRS reduces direct labor by up to 30% through automation and guided workflows. It minimizes the need for training and manual supervision, making labor more productive and less error prone.

5. Seamless WMS and ERP Integration

Using REST APIs with JSON and CSV formats, Rapyuta ASRS connects directly with Warehouse Management Systems. This enables:

- Real-time inventory updates

- Automated order assignment

- Live task tracking and reporting

With end-to-end digital visibility, fulfillment centers gain total control over order movement, SKU status, and storage activity.

6. Autonomous Battery and System Uptime

Robots monitor their battery levels and autonomously use auto-exchange stations equipped with 12 swappable units. This ensures 24/7 operation with no human intervention. Additionally, mesh Wi-Fi and redundant edge servers ensure system stability — a must for high-volume eCommerce workloads.

Is ASRS scalable for peak season or flash sale eCommerce volumes?

Absolutely. Rapyuta ASRS is modular and can scale by adding more robots, shelves, or pick stations — all without major layout changes. It’s designed for elastic growth, ideal for eCommerce peaks.

Quantifiable Impact on Order Cycle Time

Here’s how Rapyuta ASRS compares to the manual process based on actual deployment metrics:

| KPI | Manual Process | Rapyuta ASRS |

| Pick Time per Order | 8–12 minutes | 2–3 minutes |

| Pick Accuracy | ~92% | 99.9%+ |

| Average Picking Productivity | ~50 units (or lines) per hour | Up to 600 lines/hour per station |

| Required Operators per Shift | 12–15 | 3–5 |

| Storage Utilization | ~30% vertical use | >85% vertical use ~ 2.5x storage efficiency |

These improvements make Rapyuta ASRS a powerful ROI driver in eCommerce fulfillment environments.

Maintenance and Support

Rapyuta ASRS employs an advanced maintenance strategy powered by AI and IoT technologies, combining AI-based failure prediction with digitized usage data analysis to anticipate potential component failures before they occur and prevent unexpected downtime.

The system continuously monitors operating hours and usage data of each component, enabling real-time diagnostics and predictive maintenance scheduling without disrupting warehouse operations. By calculating predictive maintenance timing, it proactively schedules part replacements and maintenance activities, ensuring high system availability, reliability, and uninterrupted performance.

Rapyuta ensures high availability of its ASRS through:

- 24/7 technical support

- Nationwide network of on-site engineers

- AI-powered preventive maintenance

- Real-time system diagnostics

- Redundant power and communication systems

Downtime is minimized and service level agreements (SLAs) ensure consistent performance — essential in fast-moving eCommerce operations.

How reliable is ASRS for nonstop eCommerce fulfillment?

Rapyuta ASRS offers 24/7 uptime via robotic battery exchangers, remote diagnostics, and on-site service teams. It’s highly reliable for continuous eCommerce operations without downtime.

Conclusion: eCommerce fulfillment is evolving — and speed, accuracy, and scalability are now non-negotiable.

With growing SKU diversity, shifting consumer expectations, and tight SLAs, fulfillment centers must adapt fast. Whether handling apparel, electronics, health products, or seasonal goods, the pressure to deliver the right product on time—every time—is immense.

Rapyuta ASRS rises to meet these demands with a robust and flexible automation platform built for the complexities of modern eCommerce. It’s not just about storing more or picking faster — it’s about enabling fulfillment centers to achieve up to 10x productivity and 2.5x better space utilization, even as order volumes and product variety grow.

By addressing core bottlenecks such as:

- Labor dependency – with automation reducing reliance on hard-to-find warehouse workers

- Space inefficiency – through intelligent vertical and dense storage configurations

- Slow, error-prone processing – by enabling high-speed, accurate, and scalable operations

Rapyuta ASRS ensures businesses can meet stringent SLAs, scale seamlessly during peak seasons, and future-proof operations—all while improving bottom-line efficiency.