Introduction: Why the Future of 3PL Growth Will Be Vertical, Not Horizontal

Can your warehouse scale throughput 10x without a single square foot of expansion? Yes—with Rapyuta ASRS built for the complexity of 3PLs.

Modern third-party logistics providers (3PLs) are in a space-time bind: rising order volumes, SKU complexity, and SLA variability—but with static square footage, mounting labor costs, and constant onboarding/offboarding cycles. Traditional expansion isn’t a viable or sustainable solution.

The answer lies in rethinking infrastructure—from horizontal sprawl to vertical intelligence.

This is where next-generation automated storage and retrieval systems (AS/RS) come in, particularly those like Rapyuta ASRS, which are designed specifically for multi-client warehouse automation. ASRS adoption has historically been slow in North America due to concerns around upfront costs and uncertain ROI timelines under short-term client contracts. However, that trend is changing. With labor shortages, longer contracts, and more modular automation solutions now available, 3PLs are turning to ASRS to stay competitive and scale efficiently.

Why Traditional 3PL Operations Struggle to Scale

Why can’t 3PLs simply add more racks or people to meet growing demand?

Because physical space and human labor don’t scale linearly with complexity. As 3PLs face increasing SKU diversity, tighter SLAs, and seasonal volatility, the margin for inefficiency vanishes.

Key challenges include:

- Space constraints in urban or brownfield distribution centers

- High labor costs and chronic labor shortages

- Inflexible physical zoning for clients

- Manual picking inefficiencies

- SKU variability and storage mismatches

- Client-specific rules for picking, packaging, and inventory visibility

- CapEx sensitivity due to thin margins and short-term client contracts

- Structural restrictions in leased warehouses—such as limits on floor anchoring, electrical upgrades, or modifying mezzanines

- Downtime during reconfiguration, even with modular systems

These challenges compound as more clients and SKUs are added. Additionally, the risk of downtime becomes a critical concern.

While modern ASRS systems can achieve 97–99% uptime with proper maintenance, 3PLs must invest in contingency planning, skilled technicians, and robust system support to avoid operational disruptions.

Why ASRS Is the Strategic Solution for 3PL Scale

A well-architected ASRS for 3PLs doesn’t just store and retrieve faster—it reorganizes warehouse logic around agility, density, and intelligence.

Strategic benefits of ASRS for 3PLs:

- High-density, vertical storage that optimizes cubic space

- Dynamic bin-level logic for multi-client inventory

- Goods-to-person workflows that eliminate walking

- Built-in support for FIFO, batch, and client-specific rules

- Real-time visibility for clients via dashboards and APIs

- Phased, modular deployment to grow alongside client needs

- Flexibility to operate in leased and structurally limited spaces, thanks to anchorless, bolt-free designs

- Ability to conform around pillars, mezzanines, and fire shutters—making use of previously wasted space

Importantly, newer ASRS systems support modularity and scalability—making it easier for 3PLs to adapt quickly to new client requirements, onboarding cycles, and seasonal surges. Some systems even allow for the temporary rental of robots during peak volumes, giving operators control without long-term overhead.

Not all ASRS platforms are designed for 3PL flexibility. This is where Rapyuta ASRS stands apart.

Rapyuta ASRS: Solving the Scaling Puzzle for Multi-Client 3PLs

How does Rapyuta ASRS address the specific operational bottlenecks faced by distribution centers and 3PL providers?

Each challenge is not only addressed, but architecturally solved using a combination of modular hardware, advanced AI, and logistics-centric software logic that’s purpose-built for dynamic, multi-client environments.

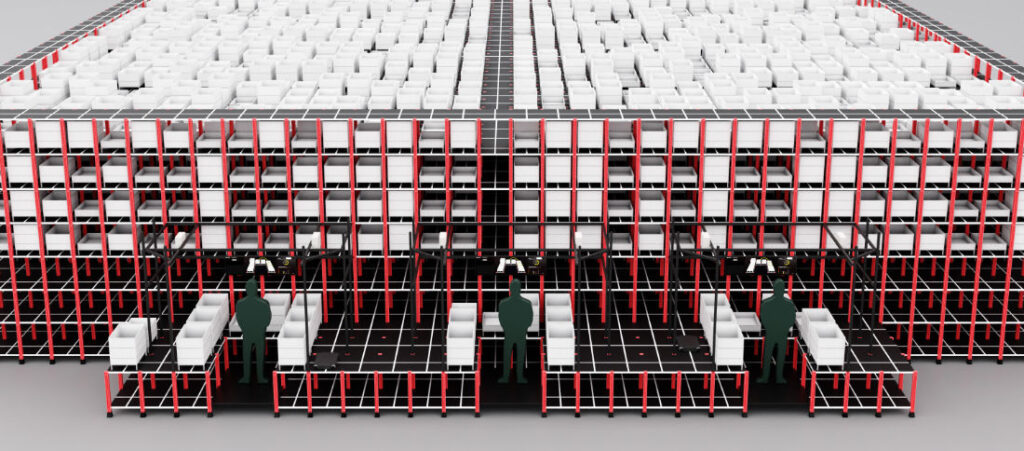

1. Maximize Throughput Without Expanding Space

Rapyuta ASRS Advantage:

- Vertical scalability up to 7 or 9 storage levels, utilizing full ceiling height of the warehouse

- Supports stacking up to 13 tiers (~38 feet) to maximize cubic usage

- 80mm thin robots, the slimmest in the category, maximize aisle efficiency

- “N-deep” bin stacking enabled by robot group control to minimize aisle space

- Flexible bin configurations (tray, short, tall) to optimize slotting based on SKU size

- 2.5x greater storage efficiency compared to conventional shelving systems

For many 3PLs, maximizing cubic volume is essential for handling SKU growth while staying within the same facility footprint. ASRS makes it possible to store more SKUs in less space—without building out.

1A. Eliminate “Dig Time” Bottlenecks with Direct bin Access

Challenge: Dig Time in Traditional ASRS

In conventional cube-based systems, retrieving a specific bin often requires:

- Robots to move multiple bins out of the way (because bins are stacked above each other)

- Vertical and horizontal shuffling just to access a target bin

Result: High latency per pick, wasted robot cycles, and reduced throughput during peak load.

How Rapyuta ASRS Eliminates Dig Time:

- Every Bin is Directly Accessible:

Rapyuta uses a racking system, not stacked bins. Each bin has a dedicated pick face, allowing direct retrieval without displacing others. - Multi-Robot, Parallel Retrieval:

Robots fetch bins simultaneously from different zones—no waiting, no queuing. - High Throughput with Smart Task Allocation:

Bin locations are optimized based on SKU velocity, with fast movers placed for quickest access. The system self-learns and reorganizes layouts. - No Congestion, No Idle Time:

Multiple robots and ports ensure continuous, non-blocking flow, unlike bottleneck-prone cube systems.

This architecture ensures high throughput, especially critical during peak demand periods.

2. Deliver SLA-Critical Orders Without Manual Reprioritization

Rapyuta ASRS Advantage:

- SLA-driven, rule-based prioritization for each client

- Dynamic task scheduling by a centralized software – rapyuta.io

- Real-time order orchestration ensuring time-critical picks without manual intervention

Tight SLAs are common in 3PL contracts. Automating prioritization helps meet those standards consistently, even in high-pressure environments.

3. Seamless Client Onboarding and Offboarding

Rapyuta ASRS Advantage:

- Virtual zoning without needing physical layout changes

- Modular FRP structure enables rapid expansion or reconfiguration

- Software interface allows client addition/removal in minutes

With increasing client turnover and short-term contracts, quick configuration changes are vital to minimizing downtime and maintaining profitability.

4. Eliminate Client Space Conflicts with Virtual Segmentation

Rapyuta ASRS Advantage:

- Shared storage grids logically segmented by client

- Dynamic bin allocation based on demand

- Full inventory isolation with pooled resource efficiency

This allows operators to handle multi-client inventory without dedicating hard infrastructure to each client.

Struggling with rigid ASRS systems?

Experience the agility of Rapyuta ASRS—built for your evolving operations.

5. Handle SKU Size Diversity with Smart Bin Allocation

Rapyuta ASRS Advantage:

- Supports trays (110mm), short bins (280mm), and tall bins (460mm)

- Real-time automated bin assignment based on SKU size/weight

- Dense, flexible storage for micro-SKUs to bulky items

ASRS systems must accommodate varied inventory. Hybrid designs that allow for both tote-based and pallet-based storage are increasingly necessary.

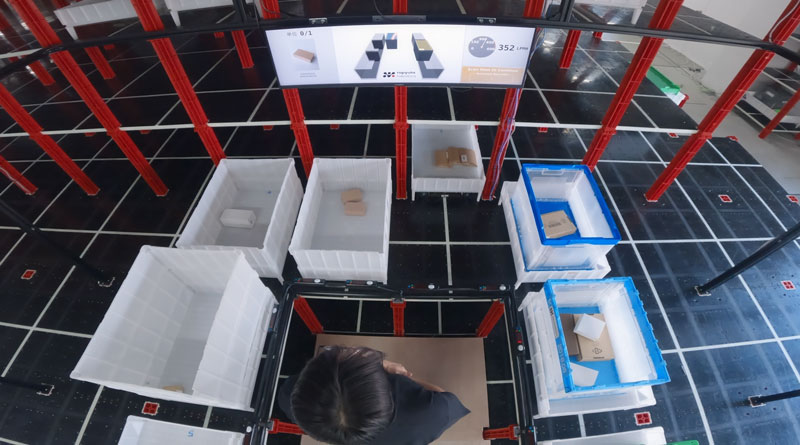

6. Execute Error Free Picking

Rapyuta ASRS Advantage:

- Supports FIFO and batch-based picking rules

- Display navigation, motion capture monitoring, and finish button validation ensure accuracy

These features eliminate human error in picking and improve compliance—especially important for regulated industries or clients with strict audit trials.

7. Reduce Labor Dependency While Improving Accuracy

Rapyuta ASRS Advantage:

- Goods-to-person flow eliminates walking

- Light-guided picking sequences improve speed and accuracy

- Battery automation ensures continuous robot operation

Labor savings are among the most compelling arguments for ASRS. In many warehouses, automation reduces labor needs by up to two-thirds, enabling remaining workers to focus on higher-value tasks like exception handling or quality control.

8. Provide Clients with Real-Time Visibility and Control

Rapyuta ASRS Advantage:

- Real-time inventory tracking with bin ID and QR code mapping

- Automated inbound, outbound, and inventory workflows

- Robot coordination using digital maps

- Centralized interface to monitor lifters, robots, and system health

Tight integration with WMS ensures that both operators and clients get real-time visibility—critical for modern SLAs, inventory accuracy, and responsive fulfillment.

9. Enable Custom Picking at Workstation Level

Rapyuta ASRS Advantage:

- Client-specific picking prompts

- Visual and text-based guidance ensuring correct execution

- Accurate fulfillment even in multi-client, high-volume environments

This customization is essential when 3PLs serve a wide range of industries, each with unique handling requirements.

10. Prove ROI with Built-in Operational Intelligence

Rapyuta ASRS Advantage:

- Dashboards track picks/hour, bin turnover, and error rates

- Data-backed ROI to validate system performance

- Phased deployment to manage CapEx and scale operations gradually

With labor cost savings, improved accuracy, and better space usage, ROI is increasingly achievable within just a few years. This helps 3PLs justify investments even with shorter client contracts or thinner margins.

Final Takeaway: Rethink Growth—Not Just Layout

True 3PL scalability isn’t about expanding your floor plan—it’s about redefining how every cubic meter of your facility works.

Rapyuta ASRS delivers a platform that grows with your client base, SKU portfolio, and throughput—boosting storage efficiency by 2.5x without compromising agility or capital.

If your warehouse strategy still relies on fixed layouts, static bins, or labor-heavy processes, it’s time to evolve. Because in today’s market, growth favors the vertically intelligent, not just the physically larger.

Need to talk about a customized solution for your 3PL?