On average, warehouse associates spend 50–60 percent of their time walking to find items within the facility. Rapyuta pick assist robots (PA-AMRs) in Distribution Centers (DCs) dramatically cut down this inefficiency. Their scalability also allows for quick adjustments to fluctuating demands, ensuring that operations remain efficient and flexible—regardless of volume changes.

In Part One of this two-blog series, we will discuss the software powering our PA-AMRs and its seamless integration with industry-standard software applications like Warehouse Management Systems (WMS), Enterprise Resource Planning (ERP), and Warehouse Execution Systems (WES) which are commonly used in warehouses. In Part Two, we will explore how AI-based software and continuous improvement drive innovation in the warehouse.

Rapyuta.io—An Overview of the Software Driving Our PA-AMRs

Intelligent Software = Better Brains

Just like the brain needs oxygen to function properly, the “brain” behind our PA-AMRs needs software to function; software that is constantly updated and optimized to maintain intelligence is a must for complex decision-making and adaptability in dynamic environments.

The continuous improvement of this software is key, ensuring that our PA-AMRs remain at the forefront of technological advancements—through regular updates, these robots become more efficient, more capable of handling a broader range of tasks, and better at navigating and optimizing workflows.

By integrating machine learning and AI within the software, the PA-AMRs can learn in real-time and improve their performance based on past experiences and real-time data analysis. This approach not only enhances operational efficiency but also ensures that our PA-AMRs can adapt to new challenges and environments, which helps us maintain our competitive edge.

Rapyuta.io – Cloud-Based Software Overview

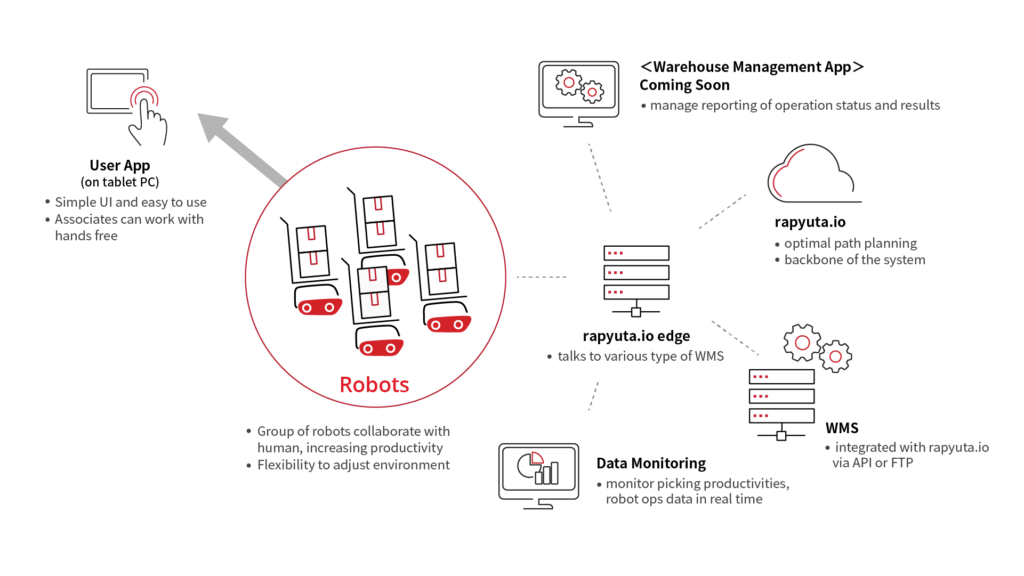

Rapyuta.io—the world’s first all-in-one DevOps platform for cloud-connected robots—is a cloud-based platform specifically designed to enhance the operational capabilities of our PA-AMRs. The browser-based dashboard provides a centralized hub for the entire enterprise, which facilitates real-time data exchange, powerful monitoring, and useful analytics. It is also designed to enable seamless scalability, remote monitoring, and the integration of PA-AMRs within the broader operational ecosystem.

By leveraging cloud computing, Rapyuta.io ensures that our PA-AMRs can operate efficiently, respond to dynamic operational demands, and continuously improve through software updates and machine learning algorithms.

Be sure to check out this video featuring our AMR Dashboard.

Local-Based Control Software Overview

Local-based control software (which includes several logical networks inside one physical network) is also crucial for the autonomous operation of PA-AMRs, providing them with continuously-relevant intelligence to navigate and perform tasks within their immediate environment. This software processes sensor data to avoid obstacles, manage task execution, and ensure safety. It also allows PA-AMRs to operate independently of the cloud, ensuring reliability and responsiveness in critical operations.

This synergy between local-control and cloud-based software ensures our PA-AMRs are both agile on the floor and seamlessly connected to the larger operational ecosystem.

How PA-AMRs Interface with WMS, WES, and ERPs

To fully integrate into operations, PA-AMRs must be able to interface with the industry-standard software applications employed in warehouses, including:

Warehouse Management Systems (WMS)

A WMS helps organizations manage and control their warehouse operations efficiently. A WMS typically includes features like order fulfillment; inventory management; receiving, picking, and packing; shipping; and the ability to track items in the warehouse.

Our PA-AMRs easily integrate with most WMS. When warehouses conduct prior integration testing, seamless data integration with the existing WMS is possible without any major issues. For example, a major B2C e-commerce company, introduced 34 PA-AMRs to support tracking work in their facility. Our PA-AMRs were able to track who did what work into a log and this information was then automatically integrated into their WMS to confirm individual productivity and other data sets.

Warehouse Execution Systems (WES)

Unlike a traditional WMS, which focuses solely on managing inventory, WES systems are hybrid platforms that bridge the gap between warehouse management systems and other control systems by taking a more comprehensive approach to actively managing tasks and resources within the warehouse. This includes task and labor management, inventory and equipment control, as well as the ability to monitor key performance indicators (KPIs) and leverage data analytics to identify inefficiencies and problem areas.

The utilization of a WES empowers our PA-AMRs to autonomously transport, sort, stack, and retrieve items, thereby improving overall efficiency. Additionally, real-time monitoring and data analysis help identify bottlenecks, constantly providing feedback to the WES on how to optimize warehouse efficiency.

Enterprise Resource Planning (ERP) Systems

An ERP platform integrates core business processes such as supply chain, manufacturing, finance, and human resources into a single system. The primary goals of an ERP system are to improve efficiency, provide better visibility and control across the entire organization, and generally streamline business operations.

The sensors and cameras on our PA-AMRs enable them to scope out and determine the specifics of the warehouse layout, a crucial feature for safe and efficient operation. The integration with Enterprise Resource Planning (ERP) systems ensures real-time data use for informed decision-making.

By interfacing seamlessly with these modern software systems, PA-AMRs ensure that physical movements within the distribution center are accurately reflected in digital records, which leads to better decision-making and resource allocation.

Get a free individual consultation today!