Adaptable to Any Situation and Change

The Rapyuta ASRS,(Automated Storage and Retrieval Systems) with its unique modular structure that allows for flexible layouts, stands out as the most dynamic automated storage and retrieval system. It can handle complex shapes and configurations that traditional automated storage systems cannot accommodate, such as mezzanine levels, multi-levels, obstructions of columns or beams, variable ceiling heights and other challenging scenarios. In today’s rapidly changing world, where even the near future is difficult to predict, its ability to adapt to any business changes has garnered interest from customers across a wide range of industries.

Why is Rapyuta ASRS considered a reliable solution for warehouse automation?

Rapyuta ASRS offers a modular, freestanding structure that adapts to irregular warehouse layouts, multi-floor operations, and evolving business needs. Its flexibility, scalability, and ability to relocate make it a highly reliable choice for industries looking for long-term warehouse automation solutions.

In this article, we will explore in detail what makes this system a truly dynamic and flexible automated storage solution, and how it provides significant benefits to our customers.

1. Flexible Configurations

As shown in the video above, the Rapyuta ASRS features a unique modular structure that allows it to be configured in virtually any shape, adapting seamlessly to the existing environment. Not only can it be installed around columns and beams, but it can also span multiple floors, such as between the ground floor and a mezzanine.

The key benefit to customers is the ability to fully utilize irregularly shaped spaces, including vertical space. One of the primary advantages of Automated Storage and Retrieval Systems (AS/RS) is their ability to maximize storage efficiency relative to warehouse volume by making better use of available height space.

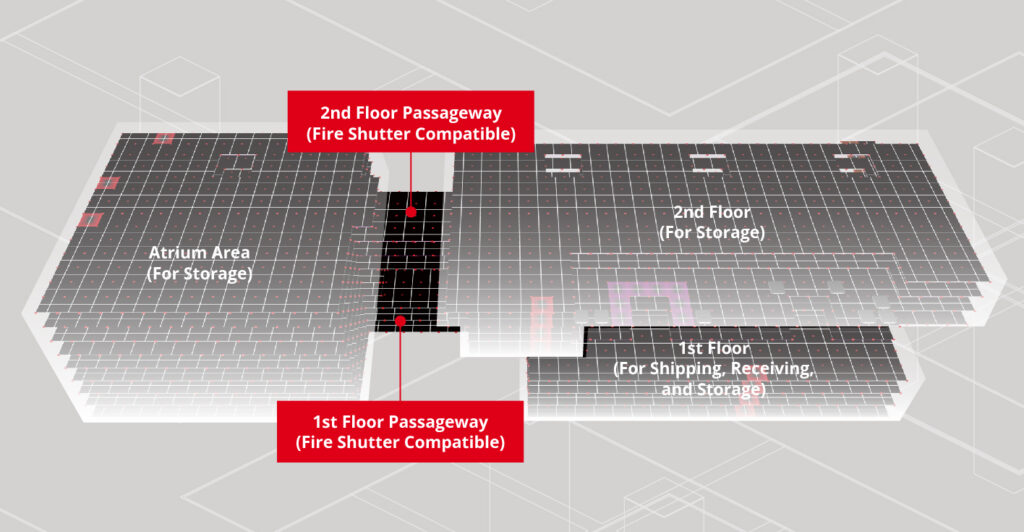

However, unlike traditional ASRSs that require a fixed proportional structure, the Rapyuta ASRS adapts to the unique shape of the facility. This enables the system to deliver not only “high storage efficiency within the automated storage system” but also “high storage efficiency across the entire warehouse or factory space.” As demonstrated by the real world cases like HobbyLink Japan, the system can be installed across both the first and second floors, extending into an adjacent open space, connecting three separate areas into a single, fully operational automated storage system.

Layout at HobbyLink Japan

Even when you need to install the system across multiple sections to achieve high storage and transportation across zones, or if there are existing fixed structures in the facility, the Rapyuta ASRS can be customized to fit the specific layout of any environment. This flexibility enhances overall storage efficiency throughout the entire warehouse space and enables the handling of long transport distances.

Benefits of Shape Flexibility for Customers:

- Improved storage efficiency not just within the automated storage system, but across the entire facility.

- Cross-zone installation allows for the automation of larger-scale warehouses.

- Can be installed in facilities with irregular layouts, such as mezzanines or spaces with non-uniform shapes.

2. Versatile Applications

What industries benefit the most from implementing Rapyuta ASRS?

Rapyuta ASRS is ideal for industries like 3PLs, ecommerce, auto parts, pharma, fast fashion brands, manufacturing, retail and wholesale. It supports both distribution centers and production lines, offering reliable automated storage, picking, parts supply, and even assembly work applications.

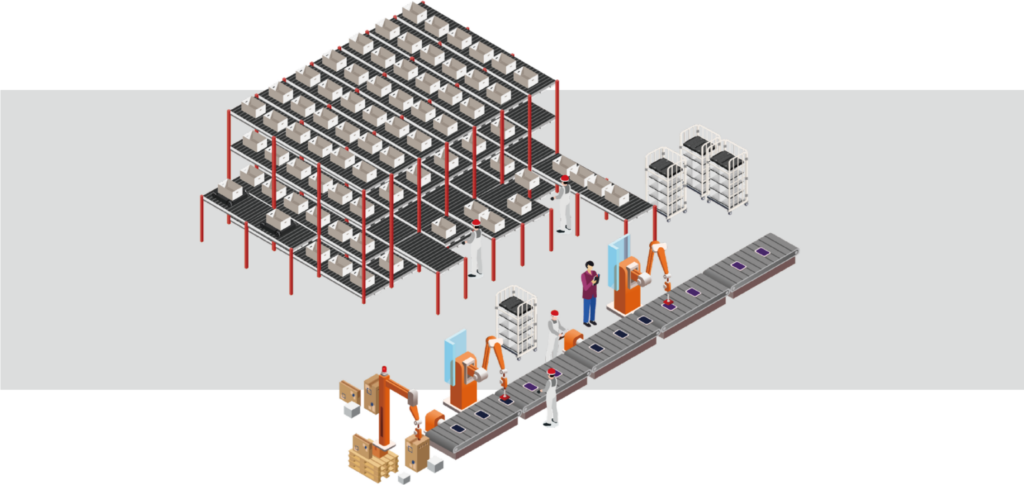

Thanks to its flexible configuration and AI-controlled robotic systems, the Rapyuta ASRS can be utilized in a variety of applications beyond traditional warehousing. In addition to warehouse uses for logistics, wholesale, and retail industries—including distribution center (DC) applications—the system can also serve as a cross-docking terminal (TC) for temporary storage and sorting by destination. In the manufacturing sector, it is ideal not only for manufacturer warehouses and aftermarket repair parts centers but also as a solution for integrated storage, management, and assembly tasks, such as supplying parts to production lines or using picking stations as assembly workstations.

Concept of parts supply to production lines using the Rapyuta ASRS

In addition to the typical applications mentioned above, the Rapyuta ASRS can be adapted for various other uses, leveraging its unique features. As a equipment manufacturer with in-house development capabilities, we offer the advantage of working closely with customers to bring their ideas to life.

Benefits of Application Versatility for Customers:

- Supports not only distribution center (DC) applications but also cross-docking terminal (TC) warehouse operations.

- Suitable for use in manufacturers’ storage and repair parts centers.

- Can be used for parts supply or assembly output in production lines at manufacturing sites.

- The flexibility in configuration offers alternatives to other traditional material handling equipment such as conveyance.

- Operates using standard 120 VAC single-phase power throughout, as opposed to high voltages (230/480/575 VAC) three-phase.

Rapyuta ASRS vs. Manual Warehousing: A Must-Read Guide to Maximizing Warehouse Efficiency

3. Scalability

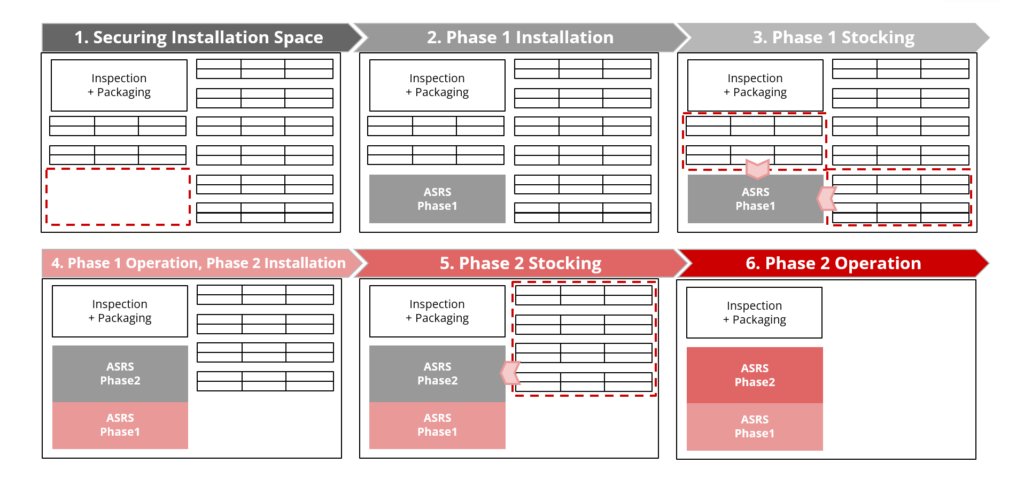

The Rapyuta ASRS can be implemented in stages, as shown in the diagram below, allowing for installation without halting the operations of existing facilities. This advantage also applies to any future expansions of the system.

The Rapyuta ASRS can be implemented in phases, allowing for installation without halting the operations of existing facilities.

While many automated storage systems offer scalability, allowing for expansion after initial implementation, the Rapyuta ASRS has the distinct advantage of being installed without interrupting existing operations from the very beginning. This eliminates any operational downtime, which can positively impact the overall ROI (Return on Investment).

Additionally, although phased implementation may take a relatively longer period to complete, the ability to start small allows customers to gradually familiarize themselves with the operation of the automated storage system. This provides benefits for both managers and on-site staff, as well as for system and software integration, enabling a smooth start on a manageable scale.

Benefits of Scalability for Customers:

- Both the initial implementation and future expansions can be carried out without halting operations.

- Avoiding operational downtime and the need for compensatory work at external or other sites offers a significant advantage in ROI.

- Phased implementation allows gradual adaptation to the Rapyuta ASRS, ensuring a smooth fit for both on-site staff and management.

4. Relocating

Is the Rapyuta ASRS system easy to relocate if business needs change?

Yes, its anchorless, freestanding design and standard 120 VAC power requirement, Rapyuta ASRS can be relocated to new warehouse sites or reconfigured within the same facility with minimal time and cost, significantly reducing long-term investment risks.

Many automated storage systems have hard fixed structures that require extensive construction work. In addition to structural installation, anchor work, and often the need to install connections for 230/480V three-phase power, the initial investment can be significant. For executives, this raises concerns about the “medium- to long-term risk” of investing several million dollars in fixed assets.

The anchorless structure of the Rapyuta ASRS also incorporates a seismic isolation design.

The fact that the Rapyuta ASRS is a freestanding system that operates on standard 120 VAC single-phase power — similar to household outlets—means that unlike traditional fixed automated storage systems, it is relocatable. In today’s world, where it is difficult to predict changes even two to three years into the future, companies are more mindful of the risks associated with their investments. In the logistics industry, many companies are relocating or establishing new facilities as part of efforts to optimize freight transport, such as by improving delivery routes and reducing truck mileage. In the manufacturing sector, frequent changes in external conditions, such as shifts in production items or the need for multi-product, small-lot production, are becoming the norm.

In such a dynamic environment, the Rapyuta ASRS offers flexibility, allowing for relocation to other sites when necessary or reconfiguration of production lines with minimal time and cost. Beyond just ROI (Return on Investment), the ability to relocate the Rapyuta ASRS offers customers a significant advantage by reducing medium- to long-term risks associated with changing external conditions.

Benefits of the ability to relocate the system for Customers:

- Unlike traditional automated storage systems that are fixed installations, the Rapyuta ASRS can be relocated to other sites.

- In production line applications, it can accommodate reconfigurations of the line.

- Operates on standard 120 VAC single-phase power, minimizing or eliminating the need for electrical work during installation or relocation.

- These features help minimize medium- to long-term risks associated with capital investment in the Rapyuta ASRS.

Conclusion – Rapyuta ASRS: Flexible, Versatile, Scalable, and Easily Relocatable Warehouse Automation for All Industries

The Rapyuta ASRS offers flexible layout options that can adapt to the internal shape of a facility, spanning multiple floors or obstructions. It can be utilized not only in typical logistics warehouses but also as a cross-docking terminal (TC), as well as in manufacturing facilities for parts or assembly output to production lines. Moreover, it supports phased implementation, allowing for small-scale initial deployment with the option for later expansion. Unlike traditional ASRS, which are fixed installations, the Rapyuta ASRS is a freestanding system that requires no anchor work, making it relocatable to other sites with minimal time and cost, in response to changes in external conditions.

In today’s VUCA era (volatility, uncertainty, complexity and ambiguity), where it is impossible to predict how the world will change even a few years from now, risk evaluation, especially when making capital investments, has become increasingly challenging. While we at Rapyuta Robotics calculate and provide estimates for ROI (Return on Investment) when proposing the Rapyuta ASRS, the system’s unique strength lies in its ability to account for medium- to long-term risks beyond just ROI considerations.

In addition to enhancing efficiency through automation, the Rapyuta ASRS also achieves operational “standardization,” ensuring consistent quality, speed, and accuracy regardless of who is working, thanks to its multi-error prevention picking stations. This makes it not just an automated storage solution, but a sustainable, human-friendly solution where robots and people can work together efficiently. It’s a solution that can benefit customers across a wide range of industries as they build safer, more ergonomic workplaces.

Meet Our Expert

Rapyuta ASRS delivers measurable results, helping warehouses achieve 10x productivity improvements and 2.5x better storage efficiency. By simplifying workflows, reducing errors, and maximizing available space, it provides a practical path to handle increasing demands without overextending resources.

For warehouses managing high SKU counts, unpredictable order volumes, and labor challenges, Rapyuta ASRS offers a clear way to meet operational goals. It’s built to adapt to your needs, scale with your business, and deliver consistent results.

Contact us today to explore how Rapyuta ASRS can transform your warehouse into a high-performance hub of efficiency and accuracy.